Nuclear power ppt

- 2. NUCLEAR ENERGY CONVERSION ï Energy conversion also termed as Energy Transformation.

- 4. NUCLEAR REACTIONS FISSION âĒ Fission would be defined as the division of single atom into multiple atoms of small size. FUSION âĒ Fusion would be defined as the joining of two or more small atoms to form a large atom.

- 5. ENERGY (FROM) FISSION Nuclear energy originates from the splitting of uranium atoms. This generates heat. BURN-UP Burnup also known as fuel utilization,it is a measure of how much energy is extracted from a primary nuclear fuel source.

- 6. RADIO ACTIVITY ï In Radio Activity Radioactive decay takes place. ï Radioactive decay is the process in which an unstable atomic nucleus loses energy. ïBy emitting radiation, such as an alpha particle, beta particle with neutrino or only a neutrino in the case of electron .

- 7. FISSION REACTOR TYPES ïžFast Breeder Reactors (FBR) ïžAqueous Homogeneous Reactors (AHR) ïžHeavy Water Moderated Reactors (HWR) ïžPressurized Water Reactors (PWR) ïžBoiling Water Reactors (BWR) ïžOrganic-Cooled Power Reactors (OCPR) ïžSodium Graphite Reactors (SGR) ïžGas-Cooled Reactors (GCR)

- 8. NUCLEAR POWER PLANTS IN INDIA âĒ Rajasthan Atomic Power Station Rawatbhata India capacity 1180Mwe âĒ Kalpakkam (Madras) Atomic Power Station India capacity 440Mwe âĒ Kudankulam Nuclear Power Plant (KNPP) India capacity 2000Mwe âĒ Narora Atomic Power Station India capacity 440Mwe

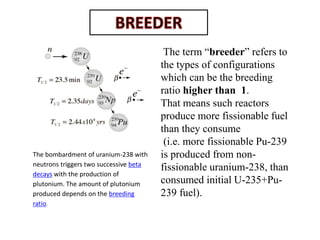

- 9. The term âbreederâ refers to the types of configurations which can be the breeding ratio higher than 1. That means such reactors produce more fissionable fuel than they consume (i.e. more fissionable Pu-239 is produced from non- fissionable uranium-238, than consumed initial U-235+Pu- 239 fuel). The bombardment of uranium-238 with neutrons triggers two successive beta decays with the production of plutonium. The amount of plutonium produced depends on the breeding ratio.

- 10. TYPES OF BREEDER REACTOR âĒ Fast breeder reactor (FBR). The superior neutron economy of a fast neutron reactor makes it possible to build a reactor that, after its initial fuel charge of plutonium, requires only natural (or even depleted) uranium feedstock as input to its fuel cycle. breeding ratio of over 1.2. âĒ Thermal breeder reactor The excellent neutron capture characteristics of fissile uranium-233 make it possible to build a moderated reactor that, after its initial fuel charge of enriched uranium, plutonium, requires only thorium as input to its fuel cycle. Thorium-232 produces uranium-233 after neutron capture and beta decay.

- 12. ïThe most common breeding reaction is that of plutonium-239 from non-fissionable uranium-238. ï The term "fast breeder" refers to the types of configurations which can actually produce more fissionable fuel than they use, such as the LMFBR(Liquid metal fast breeder reactor). ï It is possible because the non-fissionable uranium-238 is 140 times more abundant than the fissionable U-235 and can be efficiently converted into Pu-239 by the neutrons from a fission chain reaction. FAST BREEDING REACTION

- 14. WORKING OF FAST BREEDER REACTOR

- 15. ïUranium is a naturally-occurring element in the Earth's crust. ï Traces of it occur almost everywhere, although mining takes place in locations where it is naturally concentrated. . ïUranium mines operate in some twenty countries, though about half of world production comes from just ten mines in six countries, in Canada, Australia, Niger, Kazakhstan, Russia and Namibia. ï Uranium is the primary fuel for nuclear reactor. SOURCE OF FUEL

- 16. PRODUCTION OF NUCLEAR FUELS ï To make nuclear fuel from the uranium ore requires first for the uranium to be extracted from the rock in which it is found, then enriched in the uranium-235 isotope, before being made into pellets that are loaded into assemblies of nuclear fuel rods. ï At conventional mines, the ore goes through a mill where it is first crushed. It is then ground in water to produce a slurry of fine ore particles suspended in the water. The slurry is leached with sulphuric acid to dissolve the uranium oxides, leaving the remaining rock and other minerals undissolved, as mine tailings Contd...,

- 17. PRODUCTION OF NUCLEAR FUELS ï However, nearly half the world's mines now use a mining method called in situ leaching . This means that the mining is accomplished without any major ground disturbance. Groundwater with a lot of oxygen injected into it is circulated through the uranium ore, extracting the uranium. The solution with dissolved uranium is pumped to the surface. ï Both mining methods produce a liquid with uranium dissolved in it. This is filtered and the uranium then separated by ion exchange, precipitated from the solution, filtered and dried to produce a uranium oxide concentrate, which is then sealed in drums. This concentrate may be a bright yellow colour, hence known as 'yellowcake', or if dried at high temperatures it is khaki. ï The uranium oxide is only mildly radioactive

- 18. ENRICHMENT ï The vast majority of all nuclear power reactors require 'enriched' uranium fuel in which the proportion of the uranium-235 isotope has been raised from the natural level of 0.7% to about 3.5% to 5%. The enrichment process needs to have the uranium in gaseous form, so on the way from the mine it goes through a conversion plant which turns the uranium oxide into uranium hexafluoride. ï The enrichment plant concentrates the useful uranium-235, leaving about 85% of the uranium by separating gaseous uranium hexafluoride into two streams: One stream is enriched to the required level of uranium-235 and then passes to the next stage of the fuel cycle. The other stream is depleted in uranium-235 and is called 'tails' or depleted uranium. It is mostly uranium-238 and has little immediate use. ï Today's enrichment plants use the centrifuge process, with thousands of rapidly-spinning vertical tubes. Research is being conducted into laser enrichment, which appears to be a promising new technology

- 19. CLOSED NUCLEAR FUEL CYCLE

- 20. FABRICATION OF FUEL âĒ Fuel fabrication is the last step in the process of turning uranium into nuclear fuel rods. âĒ Batched into assemblies, the fuel rods form the majority of a reactor core's structure. Nuclear fuel assemblies are specifically designed for particular types of reactors and are made to exacting standards. âĒ Utilities and fabricators have collaborated to greatly improve fuel assembly performance, and an international accident-tolerant fuel program is under way. ï§uranium dioxide powder is pressed,to form small fuel pellets, which are then heated to make a hard ceramic material. The pellets are then inserted into thin tubes to form fuel rods. These fuel rods are then grouped together to form fuel assemblies, which are several meters long.