Oblique shouldered joints

- 1. OBLIQUE SHOULDERED JOINTS These joints are used where member to be joined meet at an obtuse or actute angle such as in timber truss construction where the principle rafter tie beam struts etc meet obliquely. Following are the common types of oblique joints ÔÉòBRIDDLE JOINT ÔÉòMITRED JOINT ÔÉòDOVETAILED HALVED JOINT ÔÉòBIRDS Mouth JOINT ÔÉòOBLIQUE TENON JOINT

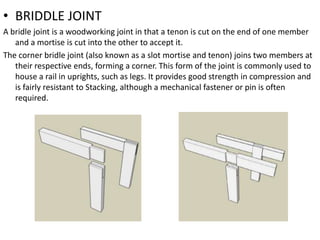

- 2. • BRIDDLE JOINT A bridle joint is a woodworking joint in that a tenon is cut on the end of one member and a mortise is cut into the other to accept it. The corner bridle joint (also known as a slot mortise and tenon) joins two members at their respective ends, forming a corner. This form of the joint is commonly used to house a rail in uprights, such as legs. It provides good strength in compression and is fairly resistant to Stacking, although a mechanical fastener or pin is often required.

- 3. • METRE JOINT • a joint made by bevelling each of two parts to be joined, usually at a 45° angle, to form a corner, usually a 90° angle. A disadvantage of a miter joint is its weakness but it can be strengthened with a spline. • Common applications include picture frames, pipes and molding.

- 4. • Birds mouth joint This joint is formed by cutting an angular notch called birds mouth in the main member, to which the other member is partly inserted and fitted

- 5. • OBLIQUE TENON JOINT This is used for connecting a horizontal member to an inclined member both the members being of bigger size the tenton of inclined member is oblique which fits into corresponding mortise hole of the horizontal member. The joint is further strengthened by bolts, keys, straps etc.

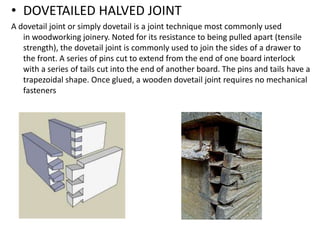

- 6. • DOVETAILED HALVED JOINT A dovetail joint or simply dovetail is a joint technique most commonly used in woodworking joinery. Noted for its resistance to being pulled apart (tensile strength), the dovetail joint is commonly used to join the sides of a drawer to the front. A series of pins cut to extend from the end of one board interlock with a series of tails cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners