OE -2013.ppt

- 1. Operational Excellence Prepared By V.Anoop Kumar Sr. Manager (Planning) Emp Code No : 302908 Jammu Udhampur Road Works ©C Jammu section A Winning Edge !

- 2. Executive Summary ? In our turbulent and uncertain times it is tempting for companies to wonder whether they do actually require a strategy. They do. Principles of strategy: ? The First Principle: The need to make difficult choices based on what information you have at the time. You take stock, gather information based on that, and then take action. The worst thing is to stay still ? The Second Principle: The need to stop analyzing and start doing, even if you are not entirely sure that what you are doing is going to turn out to be the right thing ? The Third Principle: The need to learn as you go along and modify your strategy through trial and error 2 Ī░Strategy is all about making difficult choices in the face of uncertainty and then learning as you go along and adjusting your original choicesĪ▒.

- 3. The search for difference ! If strategy is necessary, the next question is how to come up with a differentiated strategy ? ? In our industry competing companies have common client, same suppliers, the contracts are also structured in much the same way, receive their information from the same sources, use similar ways of delighting clients, offer similar services. And yet ! Some pursue genuinely different strategies ? Indeed this is what differentiates the innovators from other companies ? Playing two games: The question is, How can a company play two games simultaneously? Harvard Business SchoolĪ»s Michael Porter suggests that doing this is so difficult that most companies that attempt it will fail it. His colleague Clay Christensen suggests that a company can play two games at the same time, but that the new game needs to be separate from the main business. 3 Ī░Challenging the status quo has to be the starting point for anything that goes under the label of strategy.Ī▒ - Gary Hamel

- 4. Cases in Point ? Look at what happened to Gillette back in the 1970s when it came under attack by Bic. The strategy adopted by Bic was certainly different from Gillette. But Gillette didnĪ»t respond by adopting the Bic strategy. Instead, it invested $1 billion in its existing strategy to develop a superior product ©C the Mach 3 ©C which was then used to destroy Bic and the disposable razor threat. Who buys disposable razors now? ? Consider also the case of Swatch. In the 1970s the Swiss watchmakers competed on the basis of their craftsmanship. Then Japanese companies (like Seiko) attacked by offering better prices, the latest technology, more features. Everybody thought that this was the end of Swiss watch industry. Instead, Swatch hit back at the Japanese. But rather than trying to compete with them on their terms (that is, price and features), Swatch introduced a new competitive dimension ©C Style and Design ©C as the basis for competition and the rest is history ! 4 Ī░The demands for new knowledge and skills will be constant, no longer a value added element, but the essential factor in determining organizational survival.Ī▒ - Meg Wheatley

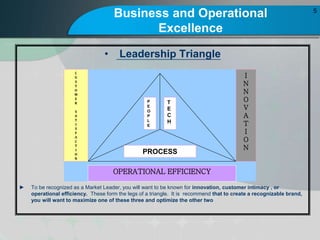

- 5. Business and Operational Excellence ? Leadership Triangle ? To be recognized as a Market Leader, you will want to be known for innovation, customer intimacy , or operational efficiency. These form the legs of a triangle. It is recommend that to create a recognizable brand, you will want to maximize one of these three and optimize the other two 5 T E C H PROCESS P E O P L E OPERATIONAL EFFICIENCY C U S T O M E R S A T I S F A C T I O N I N N O V A T I O N

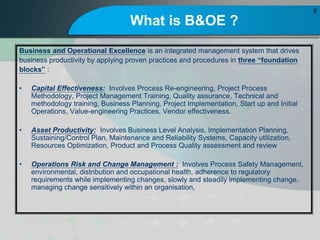

- 6. What is B&OE ? Business and Operational Excellence is an integrated management system that drives business productivity by applying proven practices and procedures in three Ī░foundation blocksĪ▒ : ? Capital Effectiveness: Involves Process Re-engineering, Project Process Methodology, Project Management Training, Quality assurance, Technical and methodology training, Business Planning, Project Implementation, Start up and Initial Operations, Value-engineering Practices, Vendor effectiveness. ? Asset Productivity: Involves Business Level Analysis, Implementation Planning, Sustaining/Control Plan, Maintenance and Reliability Systems, Capacity utilization, Resources Optimization, Product and Process Quality assessment and review ? Operations Risk and Change Management : Involves Process Safety Management, environmental, distribution and occupational health, adherence to regulatory requirements while implementing changes, slowly and steadily implementing change, managing change sensitively within an organisation, 6

- 7. Why Operational Excellence? 7 Ī░However numerous your projects, the company wonĪ»t succeed unless each of them is treated with concentrated care.Ī▒ - Robert Heller ? An integrated B&OE management system can be applied to existing and new companies and any organization which plans for expansion, mergers and acquisitions Operational Excellence can help give our organization these advantages: ? Strategic clarity about our mission, objectives, and organizational expectations; ? A culture of operational excellence; ? Best practices in process architecture; ? A well-orchestrated improvement journey and; ? Superior organizational alignment and execution

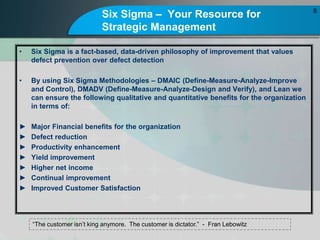

- 8. Six Sigma ©C Your Resource for Strategic Management ? Six Sigma is a fact-based, data-driven philosophy of improvement that values defect prevention over defect detection ? By using Six Sigma Methodologies ©C DMAIC (Define-Measure-Analyze-Improve and Control), DMADV (Define-Measure-Analyze-Design and Verify), and Lean we can ensure the following qualitative and quantitative benefits for the organization in terms of: ? Major Financial benefits for the organization ? Defect reduction ? Productivity enhancement ? Yield improvement ? Higher net income ? Continual improvement ? Improved Customer Satisfaction 8 Ī░The customer isnĪ»t king anymore. The customer is dictator.Ī▒ - Fran Lebowitz

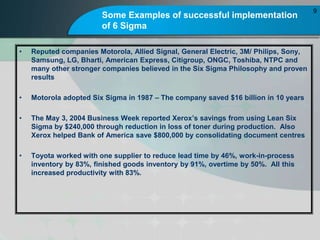

- 9. Some Examples of successful implementation of 6 Sigma ? Reputed companies Motorola, Allied Signal, General Electric, 3M/ Philips, Sony, Samsung, LG, Bharti, American Express, Citigroup, ONGC, Toshiba, NTPC and many other stronger companies believed in the Six Sigma Philosophy and proven results ? Motorola adopted Six Sigma in 1987 ©C The company saved $16 billion in 10 years ? The May 3, 2004 Business Week reported XeroxĪ»s savings from using Lean Six Sigma by $240,000 through reduction in loss of toner during production. Also Xerox helped Bank of America save $800,000 by consolidating document centres ? Toyota worked with one supplier to reduce lead time by 46%, work-in-process inventory by 83%, finished goods inventory by 91%, overtime by 50%. All this increased productivity with 83%. 9

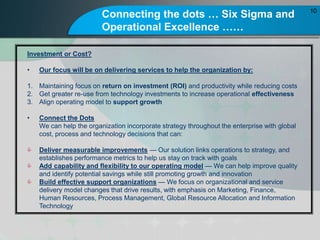

- 10. Connecting the dots ĪŁ Six Sigma and Operational Excellence ĪŁĪŁ 10 Investment or Cost? ? Our focus will be on delivering services to help the organization by: 1. Maintaining focus on return on investment (ROI) and productivity while reducing costs 2. Get greater re-use from technology investments to increase operational effectiveness 3. Align operating model to support growth ? Connect the Dots We can help the organization incorporate strategy throughout the enterprise with global cost, process and technology decisions that can: ? Deliver measurable improvements Ī¬ Our solution links operations to strategy, and establishes performance metrics to help us stay on track with goals ? Add capability and flexibility to our operating model Ī¬ We can help improve quality and identify potential savings while still promoting growth and innovation ? Build effective support organizations Ī¬ We focus on organizational and service delivery model changes that drive results, with emphasis on Marketing, Finance, Human Resources, Process Management, Global Resource Allocation and Information Technology

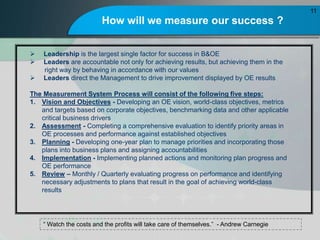

- 11. How will we measure our success ? 11 Ī░ Watch the costs and the profits will take care of themselves.Ī▒ - Andrew Carnegie ? Leadership is the largest single factor for success in B&OE ? Leaders are accountable not only for achieving results, but achieving them in the right way by behaving in accordance with our values ? Leaders direct the Management to drive improvement displayed by OE results The Measurement System Process will consist of the following five steps: 1. Vision and Objectives - Developing an OE vision, world-class objectives, metrics and targets based on corporate objectives, benchmarking data and other applicable critical business drivers 2. Assessment - Completing a comprehensive evaluation to identify priority areas in OE processes and performance against established objectives 3. Planning - Developing one-year plan to manage priorities and incorporating those plans into business plans and assigning accountabilities 4. Implementation - Implementing planned actions and monitoring plan progress and OE performance 5. Review ©C Monthly / Quarterly evaluating progress on performance and identifying necessary adjustments to plans that result in the goal of achieving world-class results

- 12. How do we initiate this ? ? Value ©C stream mapping to be done for existing processes to identify areas of opportunity ? Analysis of the same will help the team with a SMART goal statement and a project charter will be submitted to the Champion (preferably a person in the top managerial position) ? The timelines of the project completion will be mentioned in the project charter. ? A monthly report on the progress of the project will be issued to the stakeholders 12

- 13. How do we initiate this?.... contd ? Specific Points for AFCONS to Implement ? Creating Leaders capable of not only of getting the product to the customer, but also of recognizing problems before they happen and fixing them on their own. ? Create an environment where all the Engineers are cost conscious, should compulsorily prepare a Cost Benefit analysis for the activities they execute and improve for a repetitive type of job. ? Subcontract management to be improved. ? The phase wise mobilization to be well planned for optimum utilization of resources. ? Execution team and CPE should plan and maintain a strong co- ordination for the deployment of right machinery and operator for the right job. 13

- 14. How do we initiate this?.... contd ? Specific Points for AFCONS to Implement ? Minimum 85% of utilization of Major Plant and Major Equipments to be ensured at every site. External Hire equipments utilization to be closely monitored. 14

- 15. How do we initiate this?.... contd ? At Jammu Udhampur Road Project the process of Operation Excellence/ Lean Construction has been initiated in the following manner. ©C Section wise Leaders have been identified, responsible for completion of their section before COD. ©C Exhaustive detailing of all balance activities including minor finishing works have been prepared. ©C Based on the above detailing the responsibility matrix up to supervisor level has been completed. ©C Brainstorming sessions and daily monitoring is being done to identify and arrest problems, if any . 15

- 16. Benefits of OE ? All the operational benefits we normally associate with continuous improvement ©C enhanced on-time delivery, inventory turns, lead time, performance to budget and quality ©C dramatically improve once we achieve Operational Excellence. However, the true impact of Operational Excellence on an organization is much deeper and far more profound. ? Once an operation has achieved Operational Excellence, it will require very little (if any) management intervention. The employees who work directly in the flow will be capable of not only of getting the product to the customer, but also of recognizing problems with the flow before they happen and fixing them on their own using pre-established standard work. 16

- 17. Benefits of OE ? In an environment like this, when an organizationĪ»s managers and leaders are not chasing parts and people, putting out fires and going to meetings, how will they spend their time? They will be working for growing the business: meeting with new customers, interfacing with existing clients, developing new products, and breaking into emerging markets. By extension, we can also reapply the time, capital, and personnel once allocated to operations to other areas of the business. ? With Operational Excellence, we move from an environment where operations simply produces the product to one in which the operational side of the organization becomes capable of contributing to the overall growth of the business. And thatĪ»s the true power and benefit of Operational Excellence, because we canĪ»t grow the business if we donĪ»t have the time we need to do it. ? All the other benefits weĪ»ve come to expect from a journey of continuous improvement will be realized once we achieve Operational Excellence. But its true benefit is not so much what it will do for the operation, but what it will enable the operation to do for the rest of the business 17 Ī░Difficulties, opposition, criticism ©C these things are meant to be overcome, and there is a special joy in facing them and coming out on the top.Ī▒ - Vijaya Lakshmi Pandit

- 18. 18 Ī░A company surrenders tomorrowĪ»s businesses when it gets better without getting different.Ī▒ - Peter F. Drucker Thank you