OJB Resume 2016

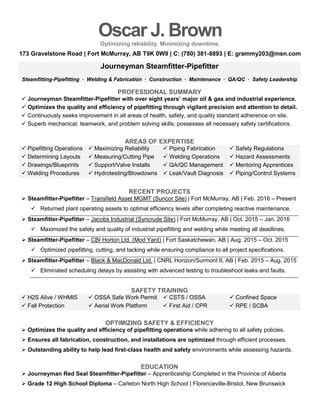

- 1. Oscar J. BrownOptimizing reliability. Minimizing downtime. 173 Gravelstone Road | Fort McMurray, AB T9K 0W9 | C: (780) 381-8893 | E: grammy203@msn.com Journeyman Steamfitter-Pipefitter Steamfitting-Pipefitting â Welding & Fabrication â Construction â Maintenance â QA/QC â Safety Leadership PROFESSIONAL SUMMARY ïž Journeyman Steamfitter-Pipefitter with over eight yearsâ major oil & gas and industrial experience. ïž Optimizes the quality and efficiency of pipefitting through vigilant precision and attention to detail. ïž Continuously seeks improvement in all areas of health, safety, and quality standard adherence on site. ïž Superb mechanical, teamwork, and problem solving skills; possesses all necessary safety certifications. AREAS OF EXPERTISE ïž Pipefitting Operations ïž Determining Layouts ïž Drawings/Blueprints ïž Welding Procedures ïž Maximizing Reliability ïž Measuring/Cutting Pipe ïž Support/Valve Installs ïž Hydrotesting/Blowdowns ïž Piping Fabrication ïž Welding Operations ïž QA/QC Management ïž Leak/Vault Diagnosis ïž Safety Regulations ïž Hazard Assessments ïž Mentoring Apprentices ïž Piping/Control Systems RECENT PROJECTS ï Steamfitter-Pipefitter â Transfield Asset MGMT (Suncor Site) | Fort McMurray, AB | Feb. 2016 â Present ïž Returned plant operating assets to optimal efficiency levels after completing reactive maintenance. ï Steamfitter-Pipefitter â Jacobs Industrial (Syncrude Site) | Fort McMurray, AB | Oct. 2015 â Jan. 2016 ïž Maximized the safety and quality of industrial pipefitting and welding while meeting all deadlines. ï Steamfitter-Pipefitter â CBI Horton Ltd. (Mod Yard) | Fort Saskatchewan, AB | Aug. 2015 â Oct. 2015 ïž Optimized pipefitting, cutting, and tacking while ensuring compliance to all project specifications. ï Steamfitter-Pipefitter â Black & MacDonald Ltd. | CNRL Horizon/Surmont II, AB | Feb. 2015 â Aug. 2015 ïž Eliminated scheduling delays by assisting with advanced testing to troubleshoot leaks and faults. SAFETY TRAINING ïž H2S Alive / WHMIS ïž Fall Protection ïž OSSA Safe Work Permit ïž Aerial Work Platform ïž CSTS / OSSA ïž First Aid / CPR ïž Confined Space ïž RPE / SCBA OPTIMIZING SAFETY & EFFICIENCY ï Optimizes the quality and efficiency of pipefitting operations while adhering to all safety policies. ï Ensures all fabrication, construction, and installations are optimized through efficient processes. ï Outstanding ability to help lead first-class health and safety environments while assessing hazards. EDUCATION ï Journeyman Red Seal Steamfitter-Pipefitter â Apprenticeship Completed in the Province of Alberta ï Grade 12 High School Diploma â Carleton North High School | Florenceville-Bristol, New Brunswick

- 2. DETAILED EXPERIENCE Steamfitter-Pipefitter Transfield Asset Management (Suncor Site) â Fort McMurray, AB (February 2016 â Present) Key Accomplishments: Preventative Maintenance ï Maximized equipment and system performance by completing comprehensive preventative maintenance in full adherence to Transfield and Suncor Energy site policies and procedures. Reactive Maintenance & Unplanned Interruptions ï Worked tirelessly to re-optimize assets to optimal efficiency during unplanned interruptions in service, helping to streamline reactive maintenance completions with colleagues in a safe, efficient manner. Meeting Deadlines & Safety Leadership ï Met deadlines with efficiency while optimizing the maintenance and repairs of Plant 6/7 during a four-week outage, and ensured superior safety and hazard awareness during another three-week outage. Steamfitter-Pipefitter Jacobs Industrial (Syncrude Site) â Fort McMurray, AB (Oct. 2015 â Jan. 2016) Key Accomplishments: Optimizing Maintenance ï Optimized piping, system, and equipment performance by conducting swift reactive and efficient preventative maintenance, following directives of Syncrude supervisor and working with Syncrude trades. Minimizing Downtime ï Minimized downtime and increased operational reliability by removing/replacing valves and piping for serving, optimizing the fabrication of piping spools and field-running pipe, and modifying piping systems. Quality Control/Quality Assurance ï Ensured maximum QA/QC compliance while selecting materials, taking vigilant assurances to ensure strict adherence to associated test packages and performing meticulous QA/QC verifications. Health & Safety ï Helped lead a strong health and safety culture by adhering to all Syncrude safety policies and procedures, assessing/reporting potential hazards, and participating in Syncrude Safe Work Plan Reviews. Steamfitter-Pipefitter CBI Horton Ltd. (Mod Yard) â Fort Saskatchewan, AB (Aug. 2015 â Oct. 2015) Key Accomplishments: New Construction & Fabrication ï Met all work scope deadlines and drove quality while building mods for the new Northwest Refinery in Redwater, AB, working with crane operators to safely rig and expedite the placing of pipes in rack.

- 3. Process & Quality Improvements ï Delivered continuous process and quality improvements by using hand rigging to place pipes on coordinates to follow all specifications, and conducted modifications to existing piping and support systems. Module Finalization & Welding ï Ensured maximum safety and efficiency while assisting welder the aligning/fit-up of weld joints, and prepared mods for shipment by building/installing brackets, clamps, U-bolts, and supports/tie downs. Steamfitter-Pipefitter Black & MacDonald Ltd. â CNRL Horizon/Surmont II, AB (Feb. 2015 â Aug. 2015) Key Accomplishments: New Construction & Commissioning ï Helped streamline the major expansion of Horizonâs vacuum distillation/bitumen recovery units, along with the safe and efficient commissioning of projects at the Conoco Phillips Surmont II Site. Welding & Fabrication ï Optimized quality, safety, and efficiency while working with a lead welder to fabricate piping spools and complete field welds, safely rigging and hoisting pipe with both crane and hand rigging equipment. Steamfitter-Pipefitter PCL Industrial â ConocoPhillips Surmont II, AB (October 2014 â Dec. 2014) Key Accomplishments: New Construction & Hydro Testing ï Maximized efficiency and optimized testing by closely reviewing test packages and ensuring hydro tests of various sizes and types of piping systems were carried out on time and without incident. QA/QC Oversight ï Ensured all test requirements met QA/QC department standards through proper documentation of blind and vent installs, removals, and trimmings to accommodate the safe filling and draining of systems. Steamfitter-Pipefitter Aecon Industrial Western (Suncor Energy) â Fort McMurray, AB (Aug. 2014 â Sept. 2014) Key Accomplishments: Safety Leadership ï Delivered exceptional safety performance on the Suncor site by contributing to safety talks, identifying/reporting hazards, and implementing scope-specific safety controls to best eliminate incidents. Identifying Deficiencies ï Increased cost efficiency, reliability, and performance by identifying deficiencies during the testing and installation of glycol/process (bitumen) piping systems of eight new chillers and six heat exchangers.

- 4. Steamfitter-Pipefitter Jacobs Industrial Services â Syncrude/Shell Albian/Nexen Long Lake (Contracts 2009, 2012, 2013 â 2014) Key Accomplishments: Maintenance & Turnarounds ï Streamlined maintenance activities and major turnarounds at the Shell Albian site through superior preventative maintenance planning and execution, documentation, and project coordination. Construction Leadership ï Helped deliver new construction projects on time on budget while leading apprentices at the MLMR Syncrude, Tank Connectivity (NLL), Natural Gas Handling (NLL), and Major Underground Projects (NLL). Steamfitter-Pipefitter Transfield Asset Management â Suncor Site (Contracts 2010, 2011, 2012) Key Accomplishments: Piping Installation ï Ensured optimal cost efficiency and safety while planning and executing the installation of both small and large bore piping (as part of booster pump house expansion to increase tailings and handling capacity). Outage/Turnaround Maintenance ï Optimized reactive and preventative maintenance during outages and turnarounds, taking a lead role in organizing high-performing teams and ensuring all quality control/assurance objectives were met. Steamfitter-Pipefitter PCL Industrial Constructors Inc. â Kearl Oil Sands Project (Oct. 2011 â Aug. 2012) Key Accomplishments: Project Controls ï Helped deliver project work scopes on schedule by maintaining and clear channel of communication, ensuring all work scope goals and objectives were achieved through vigilant planning and execution. Cross-Trades Installations ï Developed high-performance working relations with cross-trades colleagues to complete pipefitting and ironwork work scopes as part of the heavy module installations crew on the plant. Steamfitter-Pipefitter Lockerbie and Hole Industrial Contracting (Suncor Energy) (Feb. 2008 â June 2009) Key Accomplishments: Maintenance Leadership ï Delivered exceptional reliability and performance while performing maintenance over a ten-month period, and optimized QA/QC during all testing and repairs to ensure optimal asset integrity. Testing & Inspections ï Streamlined testing processes to eliminate leaks and QA/QC deficiencies, using testing equipment to check systems for leaks and conduct overall final inspections before turning over to client.