OM II_Group 9_MRF.pptx

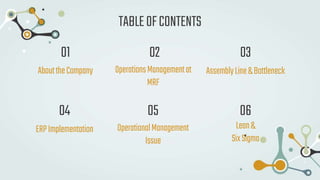

- 1. TABLEOFCONTENTS AbouttheCompany OperationsManagementat MRF AssemblyLine&Bottleneck ERPImplementation OperationalManagement Issue 01 02 04 05 03 Lean& SixSigma 06

- 2. MRFâsJourney 1946 1952 1956 1967 K. M. Mammen Mappillai started MRFâs journey as a toy balloon manufacturing unit in a shed in Tiruvottiyur in Madras in 1946 MRF ventured into the manufacture of tread rubber in 1952 put them on the road and into the big leagues By 1956, within 4 years, MRF was the market leader of tread rubber in India with a 50% share MRF became the first Indian company to export tyres to the very birthplace of tyre technology, the United States AbouttheCompany

- 3. TheJourneyContinued... 1978 1997 2007 2013 MRF developed the MRF Superlug-78, a sturdy tyre for heavy-duty trucks, country's largest selling truck tyre MRF ventured into F3 cars for the very first time MRF made a turnover of 1 Billion Dollars It also launched ZSLK tyres â the first eco friendly tyre MRF's Aero Muscle becomes the only Indian tyre to be chosen for the legendary fighter jet - Sukhoi 30 MKI

- 4. AbouttheCompany Product Portfolio â Tyres â Sports Goods- Cricket Kit, Bat â Funskool- Toy Manufacturing â Pretreads- precured retreading system â Paints & Coats Services Offered â MRF Tyres & Service (T&S) â MRF Tiretok Robotic Wheel Aligner Vehicle Safety Test Lane Diagnostic Wheel Balancer Semi-Automatic Tyre Changer A/C Recovery And Recharging Unit Electronic Headlight Aligner â MRF Tyredrome- Luxury service â MRF Fasst- air-conditioned customer care center â MRF Musclezone- For commercial vehicles

- 6. ProductionUnits Company has four production unit in every manufacturing plant: 1. Tube Plant 2. Tyre Plant 3. Mixing Plant 4. PCTR Plant For understanding the whole process we will look at the different departments:- â Production Planning Department â Plant Purchase Department â Raw materials Store Department â Production department â Shipping (dispatch) Department

- 7. Production Planning Department:- â The Central Planning at Corporate office will issue the Production plan for the coming month â Based on this, plant planning incharge will issue the monthly simulation plan to central planning, plant â production and to shipping. â According to the monthly plan and the inventory norms set by the company requirement of raw materials and consumables will be prepared â Monthly requirement of raw materials is calculated from software and it is validated every six months â Based on the monthly simulation plan of the whole manufacturing unit, each plant will make its own simulation plan â The simulation plan for 3 segments of 10 days each is prepared and micro planning is done based on that â Simulation plan for the work in process material is also prepared as material moves to other plant â Production details report is sent to central planning on a daily basis for the previous dayâs production â Plan Vs Production report is published every 10 days and also on a monthly basis. Plant Purchase Department:- Purchase items are categorized as follows: â Items which come under the head capital expenditure â Items which come under engineering spares(non capital expenditure) â Stationery and miscellaneous items (items which donât come under the preview of raw â materials) â Services (Repairing of machinery) Procedure for purchasing:- â Any person who needs a material can make a purchase requisition but it has to be authorized by the department head. This has to be routed through engineering store â Based on the indent, necessary quotations are invited and purchase orders are released. The copy of purchase order is sent to the supplier, intender, accounts, stores, corporate office PEM and a file copy for plant purchase

- 8. Raw materials Store Department:- â From the Raw material requirement for the month sent by plant planning, central make purchase arrangement â Delivery schedule is prepared, by which supplier release the materials on the specified dates to the plant â After the weighment of the raw material it is unloaded in the storage unit or the place of consumption â Technical department take the sampling and after testing the material is give one of the three tags: â Green => â OKâ â Orange=> â Holdâ â Red => â Rejectedâ â Inventory monitoring is hybrid of continuous and fixed period method â Materials are issued to production as per the indent raised by production in each plant Production Department:- It is the primary function of the company, production is carried in four plant in the manufacturing unit Following are the main functions of the production department:- â Planning for production process â Central planning will give monthly plan to this department every month, based on that a simulation plan is prepared â For this a month is divided into 3 segments, 10 days each â Material indent and receipt â The daily requirement of raw material is calculated at each plant after considering the â available inventory â The schedule production for the next day raw material indented is made to raw material store â Processing : Processing is carried out per the technical specification â Product identification and traceability â Inspection

- 9. Shipping (dispatch) Department:- â Finished goods will be received from inspection/ packing area size wise, batch wise or lot wise on the basis of production Transfer Note â Proper storage and identification of finished goods is the responsibility of shipping department â Finished goods will be stored size wise on pallets with transfer slips showing the size, quantity, date of receipt â There are stacking norms for finished goods, where ever specified norms will be followed â Shipping will publish Daily Dispatch Simulation Plan â Daily Dispatch plan is prepared based on simulation plan, allocation plan and urgency as intimated by central planning /marketing, transportation time required, availability of truck, shelf life of the product

- 11. Structure Diagram of Assembly Line at MRF Banbury Mixer Fabric Calender Extruders Wire Calender Fabric Bias cutter Tyre Building Wire cutter Bead Construction Curing Press PCI Final Inspection

- 12. Above chart shows the queuing time ( avg waiting time) in the assembly line. From this we can see that Fabric Calendering has the largest waiting time and it will be the bottleneck in the process. BottleneckIdentification

- 13. DeterminingtheSpecificcauses â5 Why â analysis was chosen to determine the specific causes for the bottleneck: Why reduced tyre production? Lack of green tyre for curing Why lack of green tyres? Too much time taken for producing green tyres Why green tyre production takes time? The calendered rolls are taking too much time to get standardized after each roll Why are the rolls not being set properly? Each roll has specified temperature and it takes time for setup Why are roll are taking time to be set at required temperature? No apparatus to check the temperature is correct or not. It was done by trial and error method

- 14. Key points : â Calendering machines are taking more time than other process â Company was using 3 roll calendering machine â which takes 2 passes of fabric to coat both side with rubber â Very time consuming and waste of money Solution: â 3 roll calendering machines to be replaced with 4 roll calendering machine available in the market â This replacement reduced the cost by 40% â It removes the process of second pass as both side will be coated in single pass Bottleneckelimination 3 roll calendering machine 4 roll calendering machine

- 16. Problem:- â MRF was using outdated systems that were not capable to keep up with the expanding operation of company â Slow availability of information, manual data entry, less flexibility,improper utilization of human resource all these resulted in increased cost to the company and its performance â Also, lot of time was spending in consolidating the information and data on time which give signal to MRF that there is need to replace the non-integrated system and independent system â The company needed a flexible and total low cost of ownership in its IT solution and decided to implement SAP ERP and SAP CRM based on the SAP NetWeaver platform The Solution:- â To determine the requirements of the company a core team â Power User Teamâ was formed for selection of suitable ERP â A detailed evaluation was performed based on various criteria as product offerings, experience in the manufacturing â After evaluation Oracle and SAP were short listed, MRF participated in aSAP summit which helped the company to take the final decision â SAP offered a clear solution for MRFâs manufacturing operations which included process as well as discrete production ERPImplementationatMRFLtd.

- 17. SD FICO MM PM PP QM HR SAP ERP Implementation:- â There were 60 members from MRF and 35 members from Siemens in implementation process, core team ensured that with collaboration implementation was on the schedule. â One of the challenge during the implementation was the companyâs system were working in silos â SAP ERP has been implemented at the companyâs Head Office in Chennai, 6 factories in Thiruvottiyur, Arakkonam, Pondicherry,Medak, Goa and Kottayam, and around 80 Sales Offices â Finance and Controlling â Sales and Distribution â Human Resource â Material Management â Production Planning â Quality Management â Plant Maintenance

- 19. Problem Definition â MRF decided to launch a new and state of the tires system for heavy vehicles â This was the first of its kind in the market of tyres â MRF wanted to make its product to end customers by the target date without any delays â The raw material was sourced from different locations and final product delivered to the customer must have all the accessories packed with it â MRF wanted their retailer and distributors to have up to the minute information regarding the product availability â Top management should ensure that there will be no issue with the delivery of the new product

- 20. From the cost analysis MRF decided to produce some of the parts in India and rest to out source in different countries. Also, MRF team up with VISTA supply chain management system to deliver the products. 1. Major components were manufactured in ASIA 2. Assembled in Japan and Thailand 3. Accessories are manufactured in Eastern Europe countries Distribution of the product:- â Assembled products from japan and Thailand were flowned to Kentucky and distributed after packaging to North America â Latin America region was covered with air freight from Kentucky â Product Supply to North and Europe and Africa: The assembled product was air shipped to Bucharest, Romania and is packaged with accessories and sent to retailers â Asia Pacific Region: The accessories are flown to Thailand and packaged with product Major Results:- â The supply chain got reduced by 40% â Increased speed to end customer and retailers â Product is launched at the same time globally without any delays Solution: Synchronizedsupplychainmanagement

- 22. Define:- Here all the processes and department of manufacturing of tyres are studied and performance is measured to find out inefficiency and wastage in the system. Measure:- Here all five processes of manufacturing that is â Banbury Mixing â Tuber, Calendering â Tyre Building â Tyre Curing All these processes were measured on different parameters for further analysis Analyse Phase:- Here all the departments are analysed, âWHY-WHYâ analysis is performed to understand the cause of the defect Also different departments are combined to clearly define the cause and effect, an example of this is show in the next slide. DMAICmethodwasusedbyMRF

- 23. Defect Area Sr. No Cause Sub causes Off Centered Bead Bead fitting and stitching 1 Finger distance low Finger distance setting off specifications 2 Bead off centred Wrong bead 3 Low pressure and dwell time Pressure setting off specifications 4 Bead setting without air trap and wrinkles Operators fault US disc setting off specifications US disc damaged 5 Drum spotting not ok Setting off specifications 6 Specific BSR off specification Operational lapse Non identified BSR Edge worn out of BSR Blisters Awling of the GT 1 Awling not done properly Improper length of the needle Improper rpm and pressure of the gun 2 Awling not done at a specific position Operational error 3 Awling not done for a specific number of times Operational error Contaminati on Curing of the GT 1 Contamination in mould Improper cleaning Contaminated Green Tyres used Use of overused mould Cured flash Damaged mould

- 24. Starvation Banbury Mixing 1 Stock properties off specification Wrong recipe Wrong polymer Polymer weight off specification Wrong oil used Oil weight off specification Wrong filler used Filler weight off specification Wrong chemical packet Wrong mixing sequence Curing of GT 2 Improper tyre shaping pressure Hydraulic leak Airline leakage Bladder pin hole Shaping regulator failed Defect Area Sr. No Cause Sub causes

- 25. Improve and Control :- 1). Loading and Unloading efficiency in Banbury mixing: â Closing of the bottom drop door and opening of the top door would happen simultaneously by using on one single push button. â Per batch around 4 seconds is saved â This would result in improving the Loading and Unloading efficiency Table below gives the comparison of the current and proposed system Important parameters Current Proposed Total number of activities 5 4 Number of non-value added activities 2 0 Average total time is taken for activities 2 and 3 together (in a sec) 8 4 Average Time is taken per batch for Loading and Unloading (in a sec) 20 16 Batches produced currently on an average per shift 235 245 Average Loading and Unloading Efficiency (%) 58.835 100 2). Defects in tyre building and tyre curing: â 3M/4M condition was used which comprises of condition to be followed, the requirement for that given condition, ways to check and maintain it â 3M/4M conditions were generated only after proper discussion with Industry guide, supervisors from the respective department and other staff in the industry having experience and knowledge Example of this Starvation and Blisters are given in the next slide

- 26. 3M Condition Requirement How to check and Maintain Method Preparation of the Green Tyre for loading Uniform application of the paint Visual, For every tyre Material Defect free Green Tyre Proper setting of components of Green Tyre Visual, For every tyre Machine Shaping PRV No cut packing (SS diaphragm), Stage 1 shaping regulator ok, Stage 2 shaping regulator ok Open and check, during PM schedule Defect free Green Tyre The specified setting of the pressure and tread centering Visual, for every tyre 3M Condition Requirement How to check Men No air traps present in Green Tyre Proper awling process done at specific distance and number of times Follow the specification, each tyre No impurities in the vents of press mould Proper cleaning of vents Visually, before loading No impurities in the vents of press mould Use of mould only till its specified life Visually, PM schedule Machine No air traps present in Green Tyre Proper rpm and pressure of pneumatic gun used for awling Visually and Pressure gauge, each tyre Material No impurities in the vents of press mould No contamination on the Green Tyre Visually, each tyre Proper awling application for removing air traps Use of proper needle for awling Visually, each tyre

- 27. THANKYOU!