Optimizing Anti-Tack Applications

- 1. intralox.comintralox.com Optimized Anti-tack application Jointly presented by Intralox and the Polymer Solutions Group Tire Technology Expo, 21 February 2018 Hannover, Germany

- 2. intralox.comintralox.com Agenda ŌĆó Welcome and introductions ŌĆó Challenges currently facing in your plants ŌĆó 3 components of a successful anti-tack application process ŌĆó Intralox solutions ŌĆō overview ŌĆó Polymer Solutions Group ŌĆō overview ŌĆó Questions and Answers

- 3. intralox.comintralox.com ŌĆó Paul Timmer, Application Engineer, Intralox Member of Intralox Tire Team with technical focus on tire applications, 10 years with Intralox ŌĆó Ed Juline, EMEA Sales Director, Polymer Solutions Group 8 years with SASCO/PSG Introductions

- 4. intralox.comintralox.com ŌĆó What current challenges are you facing in your anti-tack application process? ŌĆó What upcoming initiatives or objectives are you focusing on? LetŌĆÖs Hear From You

- 5. intralox.comintralox.com ŌĆó Personnel training and problem solving ŌĆó Mixing inconsistencies ŌĆó Porosity Issues ŌĆó New challenges with stickier, softer compounds ŌĆó Line cleanliness ŌĆó Inconsistent application ŌĆó Backside coverage ŌĆó Foam ŌĆó Solids / concentration ŌĆó Sedimentation / separation ŌĆó Blisters ŌĆó Stuck rubber ŌĆó Downstream process issues ŌĆó Impact to production ŌĆó Product quality ŌĆó Scrap ŌĆó Unscheduled downtime ŌĆó Cost incurred to reprocess rejected rubber ŌĆō Line time, labor, energy, health and safety Challenges

- 6. intralox.comintralox.com Controlled and CONSISTENT process. Even application, good backside coverage, consistent quality, limited downtime, limited waste / reprocessing Chemistry Belting Equipment Optimized Anti-Tack Application Components

- 7. intralox.comintralox.com Optimized Anti-Tack Application Components ŌĆó Equipment ŌĆó Belting ŌĆó Chemistry

- 8. intralox.comintralox.com Belt recommendation Considerations for belt choice: ŌĆó Abrasive anti-tack solution (wear) ŌĆó Hot rubber slab, 110-140┬░C (230-284┬░F) ŌĆó Small contact surface for optimal backside coverage ŌĆó Open surface required for drainage ŌĆó Strong belt to handle ball-ups ŌĆó Belt speeds: 10-40 m/min (32-130 ft/min) ŌĆó Typical belt width: 1000-1400 mm (40-56 inch)

- 9. intralox.comintralox.com Belt recommendation Belt and sprocket recommendations: ŌĆó S1700 FG NT Nylon with Nylon rods (dual rod system) ŌĆó S1700 FG Nylon with Nylon rods (dual rod system) ŌĆó S1700 Ultra Abrasion Resistant (Split) Sprockets - 16T, 14T or 12T ŌĆó Other options availableŌĆ” S1700 FG NT

- 10. intralox.comintralox.com Belt recommendation Advantages S1700 FG NT: ŌĆó Increased belt and sprocket life ŌĆó Improved backside coverage ŌĆó Decreased liquid carry-over ŌĆó Better clean-ability ŌĆó Reduced and easier maintenance 37% open area and nub pattern: easier flow of liquid through the belt 8% contact area between rubber slab and belt: More contact of liquid with rubber Rubber slab

- 11. intralox.comintralox.com Conveyor Design Gravity Take-up Min. ├ś 6 inch / ├ś 150 mm Stroke: Min. 2 %, ideally 4% of total belt lengthReturnway rollers Min. ├ś 6 inch / ├ś150 mm Belt edge guides (both sides) Carryway support: Stainless Steel wearstrips in chevron configuration Sufficient space for ball-ups to pass Dunk roller with position limiter Ensure sufficient back-tension (avoid sprocket disengagement) and storage capacity for belt elongation (minimal maintenance) Hugger strips designed such that it can deal with possible ball-ups

- 12. intralox.comintralox.com We suggest looking at the cost of using anti-tack in terms of total cost of use. What it costs to USE, not what it costs to BUY. 1. Rubber producers typically consume 20-50% more anti-tack than the optimal amount needed 2. Actual product purchase cost of anti-tack is a small percentage per ton of rubber (<$4 per ton of rubber) 3. The improper use of anti-tack causes extrusion, calendaring and molding problems that are often unjustly blamed on the downstream processes 4. Rubber producers modify their processes to adapt to their anti-tack instead of finding the best anti-tack for the compound and optimizing the equipment Total Cost of Use of Anti-Tack

- 13. intralox.comintralox.com ŌĆó Depletion or Take-Up Rate: Amount of anti-tack solution used per ton of rubber ŌĆó All anti-tacks deplete at different rates ŌĆó Field Study ŌĆō CompetitorŌĆÖs powder anti-tack and SASCO PolyCoat RLS-40 diluted to 4% solids (500 gallons) ŌĆō 500 gallons of PolyCoat RLS-40 covered twice as much rubber as the competitors dip Not All Anti-Tacks Are the Same

- 14. intralox.comintralox.com Not All Anti-Tacks Are the Same Powder with Calcium Stearate Low-Shear Dispersed into Water Slurry with Calcium Stearate Prepared Under High-Shear Mixing

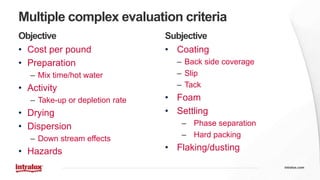

- 15. intralox.comintralox.com Objective ŌĆó Cost per pound ŌĆó Preparation ŌĆō Mix time/hot water ŌĆó Activity ŌĆō Take-up or depletion rate ŌĆó Drying ŌĆó Dispersion ŌĆō Down stream effects ŌĆó Hazards Subjective ŌĆó Coating ŌĆō Back side coverage ŌĆō Slip ŌĆō Tack ŌĆó Foam ŌĆó Settling ŌĆō Phase separation ŌĆō Hard packing ŌĆó Flaking/dusting Multiple complex evaluation criteria

- 16. intralox.comintralox.com ŌĆ£Hope for the bestŌĆØ strategy Suppliers Customers

- 17. intralox.comintralox.com PSG Automated Mixing System Layout H2O Air

- 18. intralox.comintralox.com You can do betterŌĆ”MUCH BETTER!

- 19. intralox.comintralox.com Controlled and CONSISTENT process. Even application, good backside coverage, consistent quality, limited downtime, limited waste / reprocessing Chemistry Belting Equipment Optimized Anti-Tack Application Components

- 20. intralox.comintralox.com Questions & Answers Intralox Booth 9020 Hall 21 Polymer Solutions Group Booth C238 Hall 19 Come and see us at our booths