Organizing%20 six%20sigma[1]

- 1. Organizing Six Sigma Christopher J. Zampogna Operations Management 380 Boise State University

- 2. What will be covered ŌĆó The History of Six Sigma ŌĆó Six Sigma Defined ŌĆó Brainstorming Exercise ŌĆó The Six Sigma Roadmap ŌĆó Organizing Six Sigma ŌĆó A Real-World Example ŌĆó An Exercise ŌĆó Summary ŌĆó Reading List ŌĆó References

- 3. The History of Six Sigma ŌĆó ŌĆ£Six SigmaŌĆØ originated at Motorola in 1982 ŌĆó Early adoptors ŌĆō Allied Signal (Honeywell) ŌĆō General Electric ŌĆó Six Sigma management philosophy today ŌĆō A well-developed, thorough approach to quality improvement ŌĆō Uses statistics and management by fact ŌĆō Is effective in manufacturing and services firms

- 4. Defining Six Sigma (6 ) ŌĆ£Six Sigma: A comprehensive and flexible system for achieving, sustaining and maximizing business success. Six sigma is uniquely driven by a close understanding of customer needs, disciplined use of facts, data, and statistical analysis and diligent attention to managing, improving, and reinventing business processes.ŌĆØ - Peter S. Pande6 ’ü│

- 5. Defining Six Sigma (6 ) ŌĆó The Greek symbol (sigma) refers to the amount of variation in a process around the mean value for that process ŌĆó Processes have acceptable upper and lower limits ŌĆó Six Sigma is concerned with reducing the variations to get more output within those limits ’ü│ ’ü│

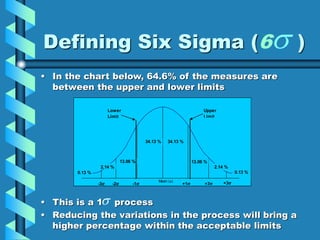

- 6. Defining Six Sigma (6 ) ŌĆó In the chart below, 64.6% of the measures are between the upper and lower limits ŌĆó This is a 1 process ŌĆó Reducing the variations in the process will bring a higher percentage within the acceptable limits ’ü│ Mean (╬╝) +1Žā-1Žā-2Žā +2Žā-3Žā +3Žā 34.13 %34.13 % 13.06 % 2.14 % 13.06 % 2.14 % 0.13 % 0.13 % Lower Limit Upper Limit ’ü│

- 7. The 6 Difference What is the Six Sigma difference ? ŌĆó one typo per page (3 sigma) vs. one typo per library (6 sigma) ŌĆó playing golf at a 6 sigma level means missing one putt every 163 years ’ü│

- 8. Brainstorming Exercise: Where are the variations? Identify six processes in your business that have variations in the output. (HINT: manufacturing, purchasing, inventory, forecasting, product design, customer service, accounting...)

- 9. The Six Sigma Roadmap ŌĆó Five steps to implementing Six Sigma9 1. Identify core processes and key customers 2. Define customer requirements 3. Measure current performance 4. Prioritize, analyze, implement improvements 5. Expand and integrate the Six Sigma system

- 10. Organizing Six Sigma ŌĆó Key Roles10 ŌĆō Leadership Team ŌĆō Champions ŌĆō Mentors (master black belts) ŌĆō Experts (black belts) ŌĆō Participants (green belts)

- 11. Key Six Sigma Roles ŌĆó The Leadership Group ŌĆō Be actively involved from outset ŌĆō Develop a strategic plan ŌĆō Establish Roles and Infrastructure ŌĆō Establish supporting policies ŌĆó Job descriptions ŌĆó Reward/Compensation systems ŌĆó Career paths

- 12. Key Six Sigma Roles ŌĆó The Leadership Group (contŌĆÖd) ŌĆō Select projects ŌĆō Prioritize projects and allocate resources ŌĆō Facilitate, guide, manage

- 13. Key Six Sigma Roles ŌĆó The Champions17 ŌĆō Find appropriate projects ŌĆō Represent projects to the leadership ŌĆō Provide coaching ŌĆō Ensure allocation of resources ŌĆō Resolve issues

- 14. Key Six Sigma Roles ŌĆó Master Back Belts ŌĆō Coach and support project leads ŌĆō Work as a change agent ŌĆō Train others in the use of six sigma tools

- 15. Key Six Sigma Roles ŌĆó Black Belts ŌĆō Highly trained experts ŌĆō Manage project leaders ŌĆō Lead project teams

- 16. Key Six Sigma Roles ŌĆó Green Belts ŌĆō Trained in the use of statistical tools ŌĆō Lead project teams ŌĆō Participate on project teams

- 17. A Real-World Example ŌĆó General ElectricŌĆÖs 6 results: - reduced invoice defects and disputes with a key customer by 98% - saved $1 million annually in contract review process (GE Capital) - developed breakthrough technology that reduced medical scan times to 30 seconds from 3 minutes - improved a key call center performance measure from 76% 99% - reduced vibrations in Power System rotors by 300% - saved $320 million in less than two years, $750 million in three years ’ü│

- 18. Exercise 1) If you have a 2 sigma process, what percentage of the output is within spec ? 2) Six Sigma originated at Honeywell ŌĆōT/F 3) Six Sigma focuses on the customer ŌĆōT/F 4) What does the Greek symbol sigma represent? 5) Six Sigma utilizes fact-based decision making ŌĆō T/F 6) Continuous improvement requires feedback and adjustments to ensure achievement of business objectives ŌĆō T/F ANSWERS: 1) 94.38%, 2) False, 3)True, 4)Standard deviation, 5) True, 6) True

- 19. Six Sigma Summary ŌĆó Project-driven management philosophy ŌĆó Relies on fact-based decision making (statistical tools) ŌĆó Requires top-down support ŌĆó Requires an infrastructure that can support quality project management ŌĆó Has been shown to have markedly positive impacts on business performance

- 20. Suggested Reading ŌĆó Breyfogle, F.W., III, Cupello, J.M., & Meadows, B. (2003). Managing Six Sigma: A Practical Guide to Understanding, Assessing, and Implementing the Strategy that Yields Bottom-Line Success. New York, New York: John Wiley & Sons. ŌĆó Eckes, George. (2001) The Six Sigma Revolution: How General Electric and Others Turned Process into Profits. New York, New York: John Wiley & Sons. ŌĆó Eckes, George. (2003) Six Sigma for Everyone. New York, New York: John Wiley & Sons. ŌĆó Foster, S. Thomas. (2004). Managing Quality: An Integrative Approach. Upper Saddle River, New Jersey: Pearson Prentice Hall. ŌĆó Kerzner, Harold. (2003). Project Management: a systems approach to planning, scheduling, and controling. Upper Saddle River, New Jersey: Pearson Prentice Hall. ŌĆó Kinicki, A, & Kreitner, R. (2003). Organizational Behavior: key concepts, skills & best practices. New York, New York: McGraw Hill. ŌĆó Pande, P.S., Neuman, R.P., & Cavanagh, R.R. (2000). The Six Sigma Way: How GE, Motorola and other Top Companies are Honing Their Performance. New York, New York: McGraw Hill.

- 21. Bibliography 1) Eckes, George. (2001) The Six Sigma Revolution: How General Electric and Others Turned Process into Profits. p.5. New York, New York: John Wiley & Sons. 2) Eckes, The Six Sigma Revolution. p.6. 3) Ibid. 4) Eckes, The Six Sigma Revolution. pp.9-10. 5) Costanzo, Chris. (2002). At Suntrust, Six Sigma is Middle ManagementŌĆÖs Baby. American Banker, June 12, 2002, Vol. 167, Issue 112. 6) Pande, P.S., Neuman, R.P., & Cavanagh, R.R. (2000). The Six Sigma Way: How GE, Motorola and other Top Companies are Honing Their Performance. New York, New York: McGraw Hill. 7) Breyfogle, F.W., III, Cupello, J.M., & Meadows, B. (2003). Managing Six Sigma: A Practical Guide to Understanding, Assessing, and Implementing the Strategy that Yields Bottom-Line Success. p.6. New York, New York: John Wiley & Sons.

- 22. Bibliography 8) Vasilash, Gary S. (1999). Missing One Putt Every 163 Years. Automotive Manufacturing and Production, Dec99, Vol. 111, Issue 12. 9) Pande, p.67. 10) Eckes, The Six Sigma Revolution. p.25. 11) Pande, chapters 7 and 8. 12) Pande, p.110. 13) Eckes, George. (2003) Six Sigma for Everyone. pp.15-26. New York, New York: John Wiley & Sons. 14) Pande, pp. 96-103. 15) Gale, Sara F. (2003). Building Frameworks for Six Sigma. Workforce, May2003, Vol. 82, Issue 5.

- 23. Bibliography 16) Kerzner, Harold. (2003). Project Management: a systems approach to planning, scheduling and controlling. Upper Saddle River, New Jersey: Pearson Prentice Hall. 17) Pande, p.119. 18) Eckes, The Six Sigma Revolution. p.43. 19) Pande, pp.123-127. 20) Ibid. 21) Foster, S. Thomas. (2004). Managing Quality: An Integrative Approach. P.404. Upper Saddle River, New Jersey: Pearson Prentice Hall. 22) Eckes, The Six Sigma Revolution. p.43. 23) Foster, pp.404-405. 24) Breyfogle, p.146.