Partitions

- 1. Glass partitions • Glass partition walls are constructed using glass sheets or hollow blocks.

- 2. 1. Glass sheet partitions • Wooden frame work is used in which glass sheets are fixed. • It consists of a number of horizontal and vertical posts spaced to divide the entire area into number of panels. • Glass sheets are kept in position in the panel either by using timber beadings or by putty.(linseed oil and whiting chalk) • Such partitions are light weight, vermin proof and sound proof.

- 3. 2. Hollow block • Hollow glass blocks are translucent units of glass, light in weight and are available in different sizes and shapes and thicknesses. • They are usually square with thickness of 10cm.(14x14cm or 19x19cm) • Jointing edges are painted internally and sanded externally to form key for mortar. • Front or back faces may be either decorative or plain and are sometimes fluted. • Glass blocks are usually laid in cement-lime mortar (1:1:4) using fine sand. • For blocks upto 15cm in height, expanded metal strip reinforcement is placed in every 3rd or 4th course. • If height of block is more than 25cm, reinforcement placed in every course.

- 4. • Another type of glass blocks are in the form of glass bricks with joggles and end grooves. ( sketch) • Glass blocks or glass bricks walls provide good architectural effect and also admit light. • They are sound proof, fire proof and heat-proof.

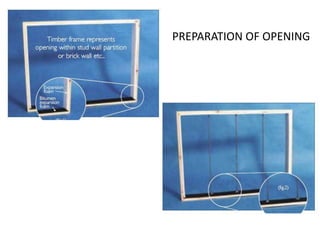

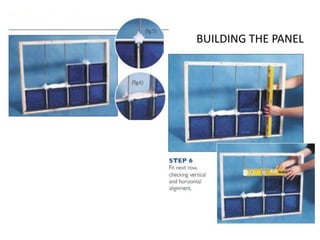

- 5. • Golden Rules - essential guidelines that need to be considered prior to preparation of the opening and before beginning installation of glass blocks. •Glass block walls are self supporting, but not load bearing. Therefore similar to doors & windows, support above should be provided in the form of a lintel. •For best integral strength, glass blocks should ideally be installed into a four sided pre- prepared opening. This opening can be timber, brick, steel, concrete or block work. •Glass blocks expand and contract with temperature change. •Glass blocks should not be installed when the surrounding temperature is 5OC and falling or 30OC and rising. •Expansion material must be incorporated to the perimeter opening & intermittently between vertical or horizontal joints if a panel exceeds 6m in any direction. Perimeter expansion should be weatherproofed by caulking with silicon and not grouted over with mortar. If grouted the joint is bridged, restricting expansion & contraction & may cause blocks to crack. •Openings must be square and perpendicular and made to suit glass block modules. Glass blocks should not be cut like masonry bricks or tiles. •Maximum panel size without intermediate support or slip joints is 25m2 with no single dimension exceeding 6min any direction

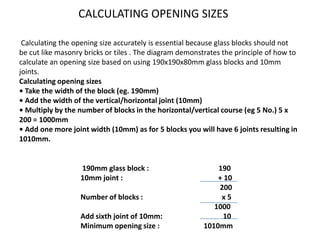

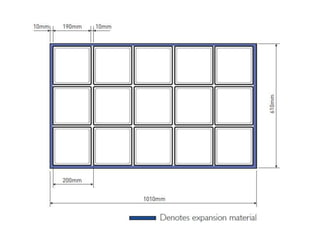

- 6. CALCULATING OPENING SIZES Calculating the opening size accurately is essential because glass blocks should not be cut like masonry bricks or tiles . The diagram demonstrates the principle of how to calculate an opening size based on using 190x190x80mm glass blocks and 10mm joints. Calculating opening sizes • Take the width of the block (eg. 190mm) • Add the width of the vertical/horizontal joint (10mm) • Multiply by the number of blocks in the horizontal/vertical course (eg 5 No.) 5 x 200 = 1000mm • Add one more joint width (10mm) as for 5 blocks you will have 6 joints resulting in 1010mm. 190mm glass block : 190 10mm joint : + 10 200 Number of blocks : x5 1000 Add sixth joint of 10mm: 10 Minimum opening size : 1010mm

- 11. FINISHING THE GLASS BLOCK PANEL SEALING AND WEATHERPROOFING THE PANEL

- 12. Steel partitions • Steel partition walls improve and create new spaces while helping to increase the worth of your home. They can be quick and easy to install and can create spaces such as a home office/study, a utility room, a bathroom or a playroom. • single skin steel partition • Double skin steel partition

- 13. Single skin steel partition A Full Steel B Steel / Glass Door C Steel / Glass / Steel D Steel / Glass E Steel / Mesh / Steel F Steel / Mesh G Drop Down Hatch H Steel / Mesh Door ideal for enclosing work area be multi-tiered to improve security and keep working areas dust-free. Panels can also be cut to accommodate an existing structure to provide an aesthetic finish. Panel heights c(mm) Panel width (mm) 2440, 2745, 3050 & 3660 300, 400, 500, 600, 700, 800, 900 & 1000

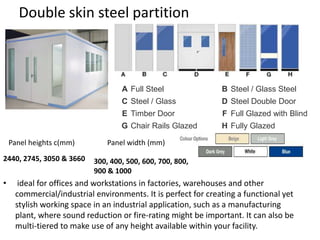

- 14. Double skin steel partition A Full Steel B Steel / Glass Steel C Steel / Glass D Steel Double Door E Timber Door F Full Glazed with Blind G Chair Rails Glazed H Fully Glazed Panel heights c(mm) Panel width (mm) 2440, 2745, 3050 & 3660 300, 400, 500, 600, 700, 800, 900 & 1000 • ideal for offices and workstations in factories, warehouses and other commercial/industrial environments. It is perfect for creating a functional yet stylish working space in an industrial application, such as a manufacturing plant, where sound reduction or fire-rating might be important. It can also be multi-tiered to make use of any height available within your facility.

- 15. Thank You….!!! Presented by :- Dipesh Patel