Penyambungan pipa pe

- 1. Mechanical Joint Butt Fusion Joint Electro Fusion Joint Push the pin POLYETHYLENE PIPE JOINTING SYSTEM PT. RUSLI VINILON SAKTI By. Edward

- 3. 1 4 4 3 3 2 2 Component of a typical Compression Fitting Body Locking Nut Clinching ring Rubber ŌĆśOŌĆÖ ring

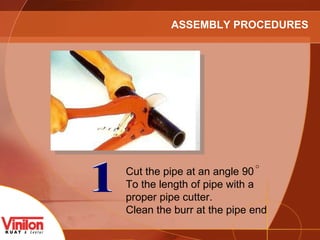

- 4. 1 Cut the pipe at an angle 90 To the length of pipe with a proper pipe cutter. Clean the burr at the pipe end ASSEMBLY PROCEDURES

- 5. 2 Insert the locking nut follow by clinching ring ASSEMBLY PROCEDURES

- 6. 3 Feed the 0-ring on the pipe end ASSEMBLY PROCEDURES

- 7. 4 Push along the pipe axis to the body of the fitting ASSEMBLY PROCEDURES

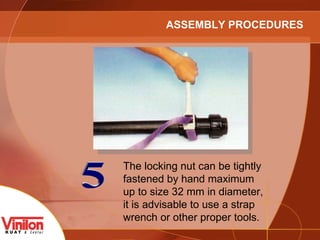

- 8. 5 The locking nut can be tightly fastened by hand maximum up to size 32 mm in diameter, it is advisable to use a strap wrench or other proper tools. ASSEMBLY PROCEDURES

- 9. 6 To ensure the fitting is fully fastened, ascertain that the locking nut exceed the last thread of the body ASSEMBLY PROCEDURES Click here

- 10. ╠²

- 11. BUTT FUSION JOINT

- 12. PT. RUSLI VINILON SAKTI Principles of butt fusion joint Principles regarding to PTt Diagram P r o c e d u r e s I n f l u e n c e s Preparation for fusion M a c h I n e I n s t a l l a t I o n Butt Fusion Fittings

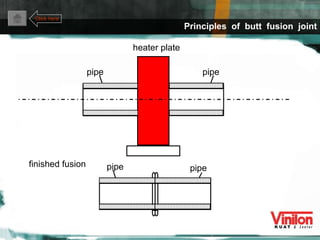

- 13. Principles of butt fusion joint Click here finished fusion pipe pipe heater plate pipe pipe

- 14. Equalisation pressure pressure (N/mm┬▓) 0,01 Equalisation time Heating time Heating pressure Fusion and cooling and pressure Fusion and cooling time time Principles regarding to PTt diagram Click here

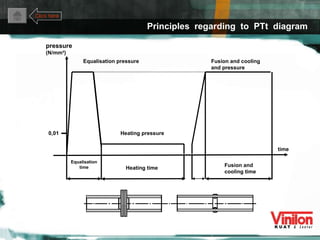

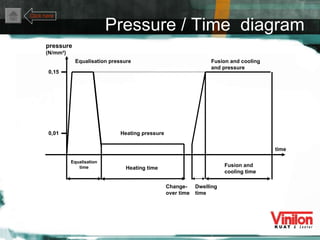

- 15. Butt fusion procedure Planing process PT. RUSLI VINILON SAKTI

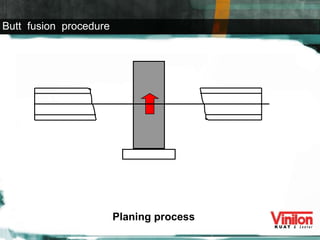

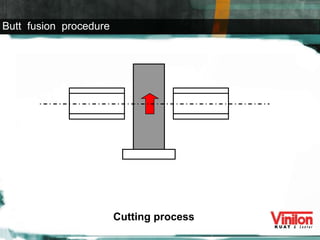

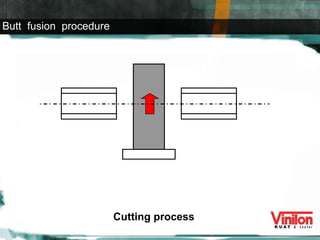

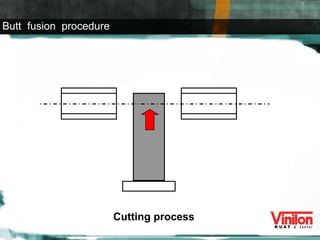

- 16. Cutting process Butt fusion procedure

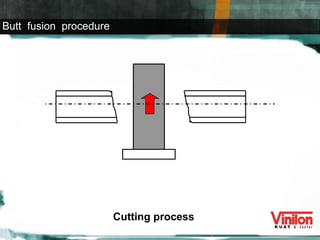

- 17. PT. RUSLI VINILON SAKTI Cutting process Butt fusion procedure

- 18. Cutting process Butt fusion procedure

- 19. Cutting process Butt fusion procedure

- 20. Cutting process Butt fusion procedure

- 21. Cutting process Butt fusion procedure

- 22. Cutting process Butt fusion procedure

- 23. Cutting process Butt fusion procedure

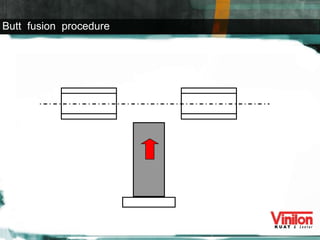

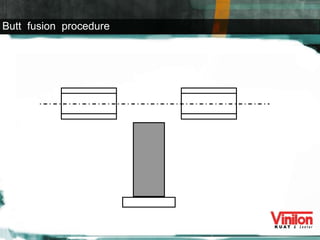

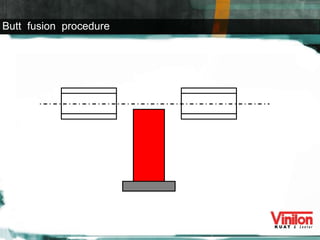

- 24. Butt fusion procedure

- 25. Butt fusion procedure

- 26. Butt fusion procedure

- 27. Butt fusion procedure

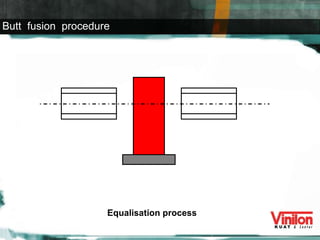

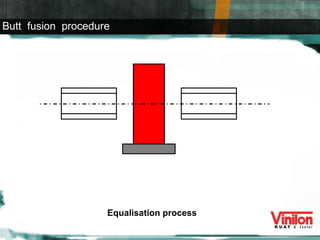

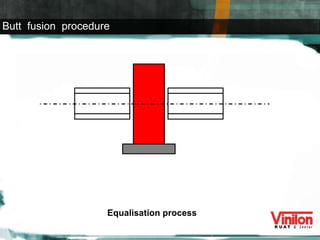

- 28. Equalisation process Butt fusion procedure

- 29. Equalisation process Butt fusion procedure

- 30. Equalisation process Butt fusion procedure

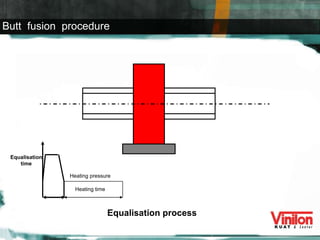

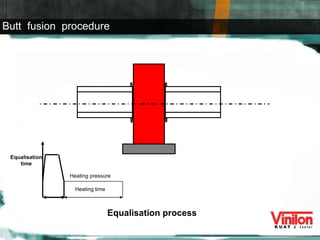

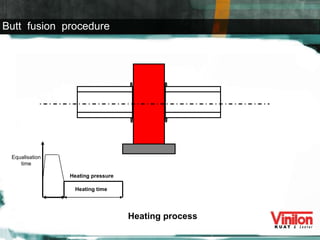

- 31. Equalisation process Equalisation time Heating time Heating pressure Butt fusion procedure

- 32. Equalisation process Equalisation time Heating time Heating pressure Butt fusion procedure

- 33. Equalisation time Heating time Heating pressure Heating process Butt fusion procedure

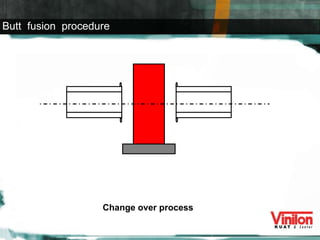

- 34. Change over process Butt fusion procedure

- 35. Change over process Butt fusion procedure

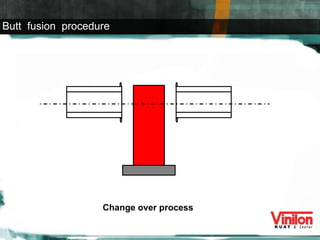

- 36. Change over process Butt fusion procedure

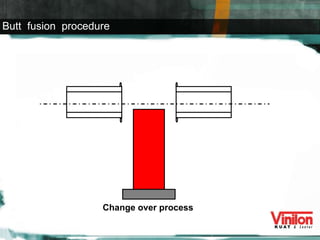

- 37. Change over process Butt fusion procedure

- 38. Change over process Butt fusion procedure

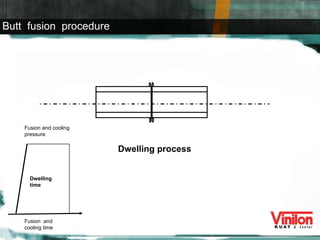

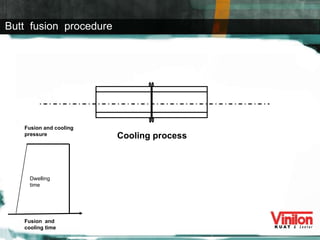

- 39. Dwelling process Fusion and cooling pressure Dwelling time Fusion and cooling time Butt fusion procedure

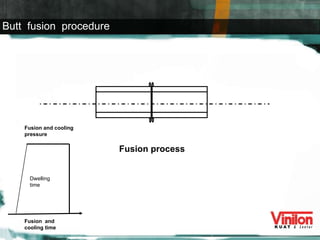

- 40. Fusion process Fusion and cooling pressure Dwelling time Fusion and cooling time Butt fusion procedure

- 41. Cooling process Fusion and cooling pressure Dwelling time Fusion and cooling time Butt fusion procedure

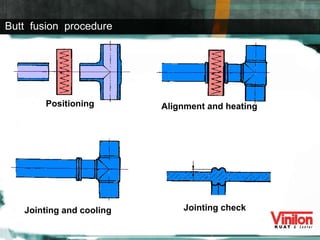

- 42. Positioning Jointing and cooling Alignment and heating Jointing check Butt fusion procedure

- 43. Pressure / Time diagram Equalisation pressure pressure (N/mm┬▓) 0,01 Equalisation time Heating time Heating pressure Fusion and cooling and pressure Fusion and cooling time time 0,15 Change-over time Dwelling time Click here

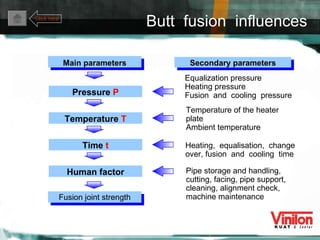

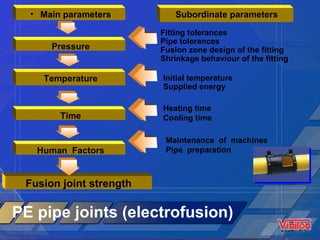

- 44. Butt fusion influences Main parameters Pressure P Temperature T Time t Human factor Fusion joint strength Secondary parameters Equalization pressure Heating pressure Fusion and cooling pressure Temperature of the heater plate Ambient temperature Heating, equalisation, change over, fusion and cooling time Pipe storage and handling, cutting, facing, pipe support, cleaning, alignment check, machine maintenance Click here

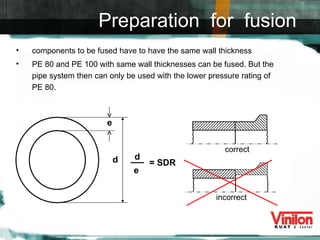

- 45. Preparation for fusion components to be fused have to have the same wall thickness PE 80 and PE 100 with same wall thicknesses can be fused. But the pipe system then can only be used with the lower pressure rating of PE 80. e d d e = SDR incorrect correct

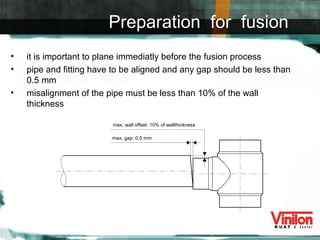

- 46. Preparation for fusion it is important to plane immediatly before the fusion process pipe and fitting have to be aligned and any gap should be less than 0.5 mm misalignment of the pipe must be less than 10% of the wall thickness max. wall offset: 10% of wallthickness max. gap: 0,5 mm

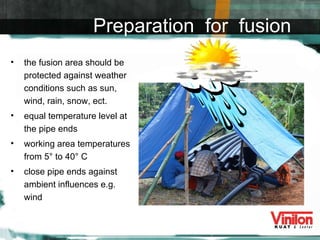

- 47. the fusion area should be protected against weather conditions such as sun, wind, rain, snow, ect. equal temperature level at the pipe ends working area temperatures from 5┬░ to 40┬░ C close pipe ends against ambient influences e.g. wind Preparation for fusion

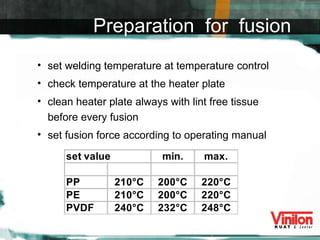

- 48. set welding temperature at temperature control check temperature at the heater plate clean heater plate always with lint free tissue before every fusion set fusion force according to operating manual Preparation for fusion

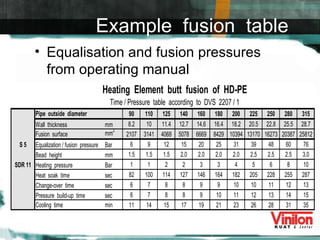

- 49. Equalisation and fusion pressures from operating manual Example fusion table

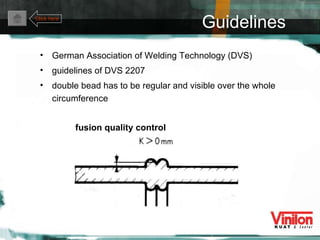

- 50. Guidelines German Association of Welding Technology (DVS) guidelines of DVS 2207 double bead has to be regular and visible over the whole circumference Click here K fusion quality control

- 51. MACHINE Plastic Welding Technology With high product quality standard

- 52. Machine types, DELTA 160 Pipe Diameter 40 mm up to 160 mm

- 53. Machine types, DELTA 250 Pipe Diameter 75mm up to 250 mm

- 54. Machine types, DELTA 315 Pipe Diameter 90 mm up to 315 mm

- 55. Machine types, DELTA 500 Click here Pipe Diameter 200 mm up to 500 mm

- 57. INJECTION MOULDING SDR 11 until SDR 17 Diameter 63 mm up to diameter 500 mm PE 100 BUTT FUSION FITTING

- 58. Click here BUTT FUSION FITTING SEGMENTED FITTING * PE 100 * diameter 40 mm up to 500 mm * SDR 11 until SDR 21

- 59. INSTALLATION

- 60. ╠²

- 61. ╠²

- 62. ╠²

- 63. ╠²

- 64. ╠²

- 65. ╠²

- 66. ╠²

- 67. ╠²

- 68. ╠²

- 69. ╠²

- 70. ╠²

- 71. ╠²

- 72. ╠²

- 73. ╠²

- 74. ╠²

- 75. ╠²

- 76. ╠²

- 77. ╠²

- 78. ╠²

- 79. ╠²

- 80. ╠²

- 81. ╠²

- 82. Click here

- 83. ELECTRO FUSION

- 84. Main parameters Subordinate parameters Pressure Fitting tolerances Pipe tolerances Fusion zone design of the fitting Shrinkage behaviour of the fitting Temperature Initial temperature Supplied energy Time Human Factors Fusion joint strength Heating time Cooling time Maintenance of machines Pipe preparation PE pipe joints (electrofusion)

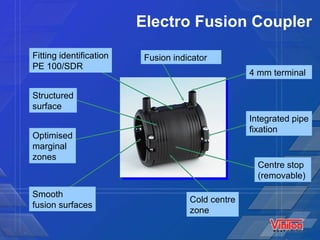

- 85. Fitting identification PE 100/SDR Fusion indicator 4 mm terminal Integrated pipe fixation Centre stop (removable) Cold centre zone Smooth fusion surfaces Optimised marginal zones Structured surface Electro Fusion Coupler

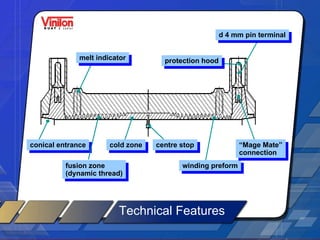

- 86. Technical Features melt indicator protection hood conical entrance fusion zone (dynamic thread) cold zone centre stop winding preform ŌĆ£ Mage MateŌĆØ connection d 4 mm pin terminal

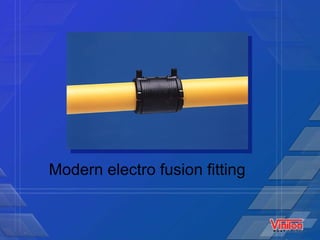

- 87. Modern electro fusion fitting

- 88. ╠²

- 89. Screw cap or Electro fusion cap 360┬░ rotatable outlet Large tapping diameter One top saddle for many applications Heating wire not in contact with medium; optimized fusion zone PE 100 4 mm pin Extra-long fusion outlet Integrated cutter, leaktight in end position Electro Fusion Tapping saddles

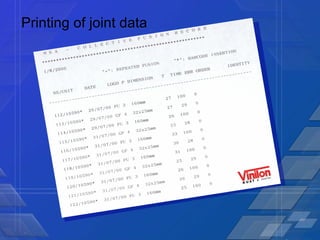

- 90. Printing of joint data

- 91. How do you overcome this problem? ?

- 92. Tapping tools designed for use with PE

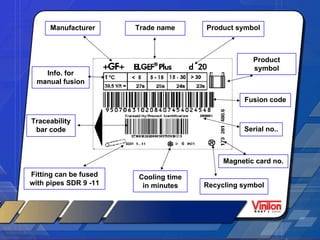

- 94. Manufacturer Info. for manual fusion Traceability bar code Fitting can be fused with pipes SDR 9 -11 Cooling time in minutes Recycling symbol Magnetic card no. Serial no.. Fusion code Product symbol Product symbol Trade name

- 95. ELECTRO FUSION EQUIPMENT Polyweld Manual Polyweld 2230

- 97. ╠²

- 98. ╠²

- 99. Quality of fusion joint

- 100. We are your preferred partner for high quality PE piping system

- 101. Thank You