PipeAssure_A4

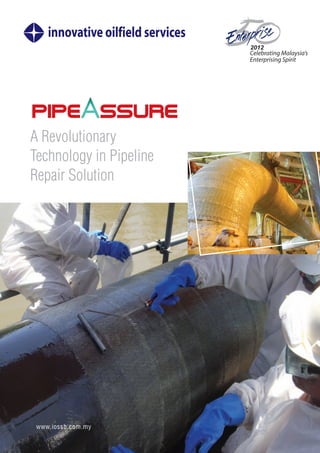

- 1. A Revolutionary Technology in Pipeline Repair Solution www.iossb.com.my

- 2. The Challenge Oil and gas pipelines deteriorate over time due to a range of structural and operational issues including manufacturing defects or degradation caused by exposure to the harsh marine environment. Current methods of pipeline repair include underwater welding, which carries considerable safety risks. The need to shut down production for extended periods can cost oil and gas companies millions in lost revenue. The Solution PETRONAS have patented a new technology that can revolutionize the repair, rehabilitation and maintenance of oil and gas pipelines: PIPEASSUREŌäó. The PIPEASSUREŌäó technology is an adhesive composite material that can be wrapped around pipelines and similar structures to protect and repair sections damaged by corrosion and other forms of degradation, even in a wet environment. The product is highly durable and resistant to moisture, capable of withstanding the conditions that subsea pipelines are exposed to. Its properties include a high glass transition temperature and strong mechanical adhesion with the ability to be applied with minimal interruption, which allows it to be used for efficient pipeline repairs in a cost effective manner while avoiding lengthy pipeline shutdowns. The technology is able to restore and provides compromised pipelines with an increased lifespan, enabling installation of a replacement pipeline section to be scheduled at their own convenience, with minimum downtime.

- 3. ŌĆ£Multiple Benefits, Cost Reduced, Trust │ę▓╣Š▒▓į▒╗Õ.ŌĆØ

- 4. Application PIPEASSUREŌäó is suitable for application on both onshore and offshore pipelines. Its broad range of applications includes pressurised vessels or piping and pipelines operating at elevated temperatures. The material comprised of an epoxy-based resin system impregnated into a glass fabric, which is then cured to form a fibre reinforced composite (FRP). This FRP material has demonstrated optimal adhesion to submersed steel substrates and the ability to be prepared and cured in sea water at a range of temperatures. Benefits The innovative PIPEASSUREŌäó technology will enable restoration of damaged pipelines efficiently, cost-effectively and with minimal production downtime with the following benefits: ŌĆó Adheres effectively to steel structures, even in a wet environment ŌĆó Is highly durable under prolonged exposure to hydrocarbons and high temperatures ŌĆó Designed to withstand underwater condition for 5 years ŌĆó Extends pipeline life (e.g. thin-walled pipelines) ŌĆó No hot work required as it eliminates the need for underwater welding, increasing the safety and convenience of pipeline repair ŌĆó Has a high glass transition temperature (thermal softening point) ŌĆó Is specially designed to repel water due to its hydrophobic properties thus creating a corrosive free environment by avoiding moisture layer from being trapped at the laminate-substrate interface and providing superior mechanical interlocking between the bonded surfaces ŌĆó Is flexible and lightweight, allowing for application to structures of various shapes and sizes ŌĆó Minimal or no shut down is required ŌĆ£Curable underwater & capable of withstanding wet environmentŌĆØ

- 5. Competitive Advantages Composite application in oil and gas industry is governed by strict international standards, namely the ISO TS 24817 and ASME PCC-2. These standards provide guidelines for qualification and design, installation, testing and inspection of composite wrapping products. As composite wrapping is considered a bonded repair, its performance is measured in terms of its bonding or adhesion strength to the substrate to complete a repair system. Testing is conducted on a range of structures used by the industry in field environment and operating conditions. Performance is measured in terms of transverse adhesion strength (strength against work done perpendicular to the axial of repair) and lap shear adhesion strength (strength against work done planar to the axial of repair). For PIPEASSUREŌäó, the transverse adhesion strength is 10.0 MPa and lap shear adhesion strength is 16.5 MPa, far greater than its competitors, which is more than 3 times the adhesion requirement of 3.45 MPa set forth in PTS 30.48.00.31-P. 1 As tested in PETRONAS; Tested as per ASME PCC2 requirement PIPEASSUREŌäó Performance: Benchmark PROPERTIES Competitor A Competitor B Competitor C Competitor D PIPEASSUREŌäó Chemical System Epoxy/Wet PU/Prepreg PU/Prepreg Epoxy/Wet Epoxy/Prepreg lay up lay up Tensile Strength (MPa) Tensile Modulus (GPa) Various glass specifications ranging from C to E E-Glass Specifications Transverse Adhesion Strength (MPa) 3.5 3.7 2.9 1.2 10.0 Lap Shear Adhesion Reading too Reading too Strength (MPa) 6.2 low low 0.6 16.5 Tg Temp (╦ÜC) 122 (90)1 80 122 55 130 Pot life at 30╦ÜC (min) 30-60 15 15 30 60 90% Full Strength Cure Time at 30╦ÜC (days) 7 3 3 7 4 Hardness (Shore D) 80 80 85 70 80 Salt Spray (unscribed) Passed 4,500 hrs

- 6. Qualification & Certification Certifications obtained in compliance with ISO TS 24817 standard from DNV Australia ŌĆó Materials Properties (out-of-water) ŌĆó Materials Properties (in-water) ŌĆó Adhesion Properties (out-of-water) ŌĆó Adhesion Properties (in-water) ŌĆó Dielectric ŌĆó Cathodic Disbondment ŌĆó Weathering Tests ŌĆó Type A: Wall Loss (out-of-water) ŌĆó Type A: Wall Loss (in-water), including unrepaired specimens ŌĆó Type B: Leak (out-of-water) ŌĆó Type B: Leak (in-water) Environmental and Safety The PIPEASSUREŌäó technology overcomes some of the significant health and safety concerns associated with the repair of subsea pipelines, through: ŌĆó A reduction of organic pollutants in the marine environment as a result of improved pipeline repair and maintenance methods ŌĆó Eliminating the need for underwater welding, creating a less hazardous method of pipeline repair.

- 7. www.iossb.com.my Innovative Oilfield Services Sdn Bhd (383695-M) Headquarters B07-G, Paragon Point 1, Jalan Medan PB5 Medan Pusat Bandar 5, Seksyen 9 Pusat Bandar Baru Bangi, 43650 Bangi Selangor Darul Ehsan, MALAYSIA. Tel: +6 03 8926 1261 Fax: +6 03 8926 1263 Email: admin@iossb.com.my Labuan Office Lot 8, Jalan Arsat Ranca-Ranca Light Industrial Estate 87008 W. P. Labuan, MALAYSIA. Tel: +6 087 583 261 Fax: +6 087 583 263 Terengganu Office Lot No. OYP2/03/26 Open Yard KSB, Phase 2 Kemaman Supply Base 24007 Kemaman Terengganu Darul Iman, MALAYSIA. Tel: +6 09 8623 951 / 52 Fax: +6 09 8623 950 Sarawak Office Lot 2297, Block 2, MCLD 2nd Floor, Pujut 5, 98000 Miri Sarawak, MALAYSIA. Tel: +6 085 651 730 Fax: +6 085 650 730 Innovative Manufacturing Services Sdn Bhd No.8, Jalan 8/16 Taman Industri Selaman, Seksyen 10 43650 Bangi, Selangor Darul Ehsan MALAYSIA. Tel: +6 03 8926 1264