Pipeseal data sheet

0 likes95 views

PIPESEAL is an epoxy paste designed to quickly seal cracks, holes, and leaks in pipes made of materials like copper, steel, lead, and cast iron. It hardens within 5 minutes when applied and heated with a heat gun. PIPESEAL is 100% solids with no VOCs, making it environmentally friendly. It can seal leaks up to 1/2 inch in diameter and withstand pressures over 1200 psi. To use, the resin and hardener must be thoroughly mixed together and applied to the leak, then heated to cure fully within minutes.

1 of 3

Download to read offline

Recommended

Elastaseal data sheet

Elastaseal data sheetDale Stauffer

Ėý

This document summarizes the properties and application of ELASTASEAL, a flexible epoxy coating designed for applications requiring high elongation. ELASTASEAL can tolerate expansion and contraction, adjusts to freeze-thaw cycles, and provides corrosion protection for surfaces like cooling towers, expansion joints, and concrete. It is a 100% solids, solvent-free coating that offers excellent adhesion and flexibility with elongation up to 300%. ELASTASEAL can be applied to surfaces like metal, concrete, wood, and geotextiles, and is suitable for uses like tank linings, secondary containment, and crack repair.Panseal paste grade data sheet

Panseal paste grade data sheetDale Stauffer

Ėý

PANSEAL Paste Grade is a two-component, no-VOC epoxy paste designed for steel tank repairs. It bonds well to steel, concrete, and other surfaces. It can seal cracks and leaks and is suitable for vertical and overhead applications due to its thick viscosity. PANSEAL Paste Grade dries hard in 8 hours at room temperature and can be topcoated within 14 days or machined after curing.Silvershield data sheet

Silvershield data sheetDale Stauffer

Ėý

This document provides product data for SilverShield 5000X, a two-part epoxy coating with zinc flakes. It can be used indoors or outdoors to protect surfaces like pipes, tanks, and structural steel from corrosion. The coating has excellent adhesion and flexibility, provides a metallic silver finish, and protects in temperatures from -18 to 121 degrees Celsius. It is a 100% solids coating that is easy to apply by spray, brush, or roller in thicknesses between 4-12 mils.Panseal gallon data sheet

Panseal gallon data sheetDale Stauffer

Ėý

PANSEAL is a unique epoxy coating formulated for corrosion protection of surfaces like cooling towers, storage tanks, and AHU drain pans. It seals leaks immediately, has a high-solids formula that is solvent-free and fire rated. PANSEAL bonds well to surfaces even under less than ideal conditions, provides excellent chemical resistance, and is suitable for uses like tank linings, pipeline coating, and corrosion protection of steel, concrete, and other materials. It offers properties like flexibility, adhesion, and resistance to chemicals, moisture, abrasion, and temperatures from -20 to 250 degrees Fahrenheit.Durapatch data sheet

Durapatch data sheetDale Stauffer

Ėý

This document provides information on a novolac epoxy paste called DURAPATCH that is designed for quickly patching, sealing, and repairing cracks, holes, and leaks. It can repair surfaces made of metal, plastic, fiberglass, and concrete. DURAPATCH cures within minutes, allowing for reduced downtime. It is suitable for field and machine shop repairs. The paste is self-priming, trowelable, sands and machines well, and has excellent bonding strength for many commercial and residential repairs. The kit contains resin, hardener, and a trowel for mixing and applying the product.Dx 5400 data sheet

Dx 5400 data sheetDale Stauffer

Ėý

This product data sheet provides information on DX-5400, a high temperature resistant novolac epoxy coating and sealant. It is a 100% solids, solvent-free coating that offers chemical resistance to acids, caustics, and petroleum products. It can withstand continuous temperatures up to 450°F and intermittent temperatures up to 500°F. The product has a glossy finish, requires minimal surface preparation, and offers quick return to service within 24 hours at 77°F.How to reduce hot forging costs through innovative techniques?

How to reduce hot forging costs through innovative techniques?Srikar Shenoy

Ėý

This presentation gives successful industrial case studies of cost reduction in hot forging by the use of:

1. Anti-scale protective coatings to prevent rejections due to scaling, reduce or eliminate shot blasting, reduce decarburization in heat treatment, hot rolling and hot forging.

2. Environment friendly die lubricants that eliminate pollution and increase die life.

3. Zero maintenance die lubricant spraying systems that ensure maximum uptime and no unplanned downtime during hot forging.Plastifloor 1 8 inch flakes floor

Plastifloor 1 8 inch flakes floorPlasti-Chemie GmbH

Ėý

Plastifloor CF 1/8" SL is a methyl-methacrylate based, self-leveling flooring system with decorative flake broadcast. It fully cures in one hour, reducing downtime, and provides a seamless, impervious floor that is easy to clean and maintain. The system offers excellent chemical resistance and UV resistance for long-term color performance in applications such as grocery stores, hospitals, restaurants, and factories. It requires no waxing or stripping for maintenance.Crane composite cleanroom

Crane composite cleanroomDutco Tennant LLC

Ėý

We at Dutco Tennant LLC supply the exceptional Hygienic FRP Wall Cladding range from CRANE Composites to the Middle East. They are the worldâs leading manufacturer of premium Hygienic Wall Cladding and Ceiling tiles made from FRP. Crane Composites FRP wall panels combine expertise in composite material science, process, and technology with a deep understanding of End-user needs to deliver innovative products that outperform traditional building material such as Ceramic, Paint, PVC wall cladding & Acrylic panels, metals and woods.

Cost Reduction In Heat Treatment, Hot Rolling and Hot Forging by the use of P...

Cost Reduction In Heat Treatment, Hot Rolling and Hot Forging by the use of P...Srikar Shenoy

Ėý

This presentation outlines an innovative concept to reduce cost in heat treatment, hot rolling and hot forging. Industrial case studies and photos are included.Gypsum and its products

Gypsum and its productsDr.shiva sai vemula

Ėý

The document provides an overview of gypsum and its products. It discusses the history, terminology, composition, properties, uses, and recent developments of gypsum. Specifically, it covers:

- The origins and various forms of natural gypsum.

- The terminology used to describe gypsum products like casts, dies, and models.

- The composition of gypsum products, including the main reactive ingredient (calcium sulfate hemihydrate), additives like accelerators and retarders, and coloring agents.

- The properties of gypsum, including the theories of setting reactions, stages of setting, setting expansion, and factors that affect setting time, strength, and water-powder ratio.Polymer Product Technical Datasheet Template

Polymer Product Technical Datasheet TemplateTDSmaker

Ėý

Here is a âPolymer Product Technical Datasheet Templateâ. TDSmaker offer you free Datasheet/ Specsheet/ Techsheet. Visit to ( https://www.tdsmaker.com ) to get start with free template.ZINC PHOSPHATE CEMENT

ZINC PHOSPHATE CEMENTLabeed Ahmed

Ėý

Zinc phosphate cement is an older luting cement that serves as a standard for comparison. It has low hardness and high solubility. When mixed, the powder and liquid undergo an exothermic reaction where zinc ions are released and react with aluminum and phosphoric acid to form a zinc aluminophosphate gel. It has good compressive strength but no chemical adhesion and can cause pulp irritation due to its initial low pH. The powder contains mainly zinc oxide and magnesium oxide while the liquid contains phosphoric acid, water, and aluminum.DENTAL PLASTER

DENTAL PLASTERAnubhav Sharma

Ėý

This document provides information about dental plaster, including:

- It thanks teachers who provided the opportunity to do a project on dental plaster, which helped with research.

- Dental plaster is calcium sulfate hemihydrate that is used to make molds and casts for dental prostheses and restorations.

- The setting reaction involves the hemihydrate dissolving in water and re-crystallizing as calcium sulfate dihydrate with the release of heat.

- Dental plaster must be properly mixed with water at the correct water-to-powder ratio to avoid porosity and ensure strength of the final cast.Both 2016 shanghai development of innovative ultra high temperature coatings ...

Both 2016 shanghai development of innovative ultra high temperature coatings ...Yuguo Cui

Ėý

This document discusses the development of innovative ultra-high temperature coatings for corrosion protection of industrial process vessels and piping. It describes how conventional epoxy coatings have limitations above 100°C and introduces next-generation hybrid coatings that can withstand temperatures over 180°C. Test results are presented showing these hybrid coatings passed autoclave testing at 180°C for 7 days with no blistering or softening, demonstrating their ability to provide long-term corrosion protection at high temperatures.Advancements in Ceramic Coating Technology for the Power Generation Industry ...

Advancements in Ceramic Coating Technology for the Power Generation Industry ...Aldrin Arquillano

Ėý

The document discusses advancements in ceramic coating technology for use in high-temperature industrial processes. Next-generation hybrid coatings are able to withstand temperatures above 200°C while providing excellent erosion and chemical resistance. These solvent-free coatings use inorganic chemistry based on silicon, which offers extreme thermal stability compared to traditional organic coatings that exhibit limited success above 100°C. The coating can withstand temperatures up to 265°C dry and 200°C wet, is highly wear resistant, and provides corrosion protection in acidic environments like those containing sulfuric acid.Industrial flooring

Industrial flooringsonali parashar

Ėý

This document provides information on various floor and wall coating products from LightDuty Floor& Wall Coatings. It describes multiple polyurethane, epoxy resin, and polyurethane floor coating systems that offer properties like chemical resistance, abrasion resistance, flexibility, slip resistance, and ease of cleaning. The coatings have a range of applications in industrial, commercial, and institutional settings depending on the specific product. Technical data on properties like bond strength, hardness, and permeability are also provided for each coating.Liqtro Ascella (Product Data Sheet)

Liqtro Ascella (Product Data Sheet)Eko Kiswanto

Ėý

LIQTRO ASCELLA is a water-miscible metal working fluid that produces a milky white emulsion when mixed with water. It can be safely used on ferrous and non-ferrous metals. The high oil content provides good machining performance and corrosion protection. It contains biocides to prolong the service life. The product is recommended at treat rates of 5-10% for general and difficult to machine materials and can be used as a 5% hydraulic fluid.Controlling decarburization during hot rolling of rail steel

Controlling decarburization during hot rolling of rail steelSrikar Shenoy

Ėý

Decarburization of steel during hot rolling makes the hot rolled products prone to low fatigue life. This is especially true in the case of hot rolled rail steel and automobile leaf springs. The presentation gives a practical technique to substantially reduce decarburisation and ensure uniform hardness of hot rolled steel. Prevention of welding / sticking of billets at high temperature, reduced scale pits on hot rolled material, reduced scaling and decarburisation due to billet over-heating in furnace and slightly increased yield are some of the other benefits enabled by use of this technique.Hydrocolloids

HydrocolloidsDrmumtaz Islam

Ėý

This document discusses reversible hydrocolloids, which are polysaccharide colloidal suspensions used for dental impressions. Reversible hydrocolloids exist as either a sol or gel, transitioning between the two states during the impression process. They are extracted from seaweeds and set via cooling and physical bonding. Examples include agar, which is supplied in tubes or syringes and sets in the mouth. Reversible hydrocolloids are dimensionally unstable due to water absorption and evaporation, but provide accurate impressions and are easy to use.White paper - investigating the effects of multiple re-use of Ti6Al4V powder ...

White paper - investigating the effects of multiple re-use of Ti6Al4V powder ...Lucy Grainger

Ėý

- The document investigates the effects of repeatedly re-using Ti6Al4V metal powder in additive manufacturing builds over 38 total builds using a Renishaw AM250 system.

- Analysis found a small but steady increase in oxygen and nitrogen levels in the powder as builds increased, with oxygen levels exceeding specifications after around 16 builds. However, nitrogen levels remained within specifications.

- Physical properties of the powder like particle size distribution and flow were also affected, but the changes were minor and not expected to impact the manufacturing process or part quality.

- It was concluded that repeatedly re-using the powder up to 38 times did not significantly alter the powder properties or composition enough to require powder disposal under normal manufacturing conditions.LACS Ceramic Coating Presentation (Shared File)

LACS Ceramic Coating Presentation (Shared File)Jeff Abshire

Ėý

Louisiana Advanced Coating Solutions provides proprietary ceramic coatings for industrial, automotive, aerospace, military, and other applications. Their coatings offer benefits such as corrosion and heat resistance from 500°F to over 2000°F, various thickness and color options, and increased performance and lifespan of coated parts and equipment. Key products include heat cured, high temperature, dry film lubricant, clear, heat dissipating, and NIR coatings. The company conducts thorough testing of coatings' durability, corrosion protection, hardness, flexibility, chemical resistance, adhesion, abrasion resistance, and thermal barrier properties per ASTM standards. Ceramic coatings can significantly increase equipment lifespan through reduced wear and maintenance needs.Weh61882 61886 high temperature resistance finish coat (200-600â) (all k...

Weh61882 61886 high temperature resistance finish coat (200-600â) (all k...GOPAL RAMALINGAM

Ėý

This document describes a high temperature resistant finish coat that can withstand temperatures between 200-600°C. It is available in various colors and grey. It has high temperature resistance and anti-corrosive properties. The coating has a double component formulation and can be applied by brushing, rolling, or spraying. It dries quickly and has strong adhesion. It provides corrosion protection for 3-5 years when applied in 2-3 coats to a thickness of 50-80um.Renishaw Ti6Al4V metal powder re-use study

Renishaw Ti6Al4V metal powder re-use studyLucy Grainger

Ėý

There are various issues and concerns surrounding the re-use of metal powders through metal powder bed processes. This presentation discusses some of these issues and presents the latest results of a powder re-use study, in which a single batch of Ti6Al4V alloy powder was used over 38 routine builds. Chemistry and physical properties of the powder were assessed over the period of the study as well as tensile properties of built test bars.Zinc oxide eugenol

Zinc oxide eugenolDr. Roshni Maurya

Ėý

Zinc oxide-eugenol (ZOE) is a dental cement that has been used for over 150 years. It is used for multiple applications including impressions, temporary fillings, root canal fillings, cementing, and surgical dressings. ZOE cement sets via a chemical reaction between zinc oxide and eugenol. It has low strength but is biocompatible. Modified versions with additions like EBA or polymers have improved properties but ZOE remains useful due to its favorable pulpal response and low cost.Durapatch

Durapatch Dale Stauffer

Ėý

âĒ All Purpose Quick Cure Epoxy Paste

âĒ Hardens in 5â 15 minutes depending on ambient temperature (down to 38°F)

âĒ Ideal for immediate field use repairs

âĒ Trowellable - ideal for vertical surface repairs

âĒ Self-priming - bonds chemically and mechanically to the substrate

âĒ Can be sanded, drilled, tapped and machined

âĒ 100% solids - No VOCsdental_cements.pdf

dental_cements.pdfssuser93f9e8

Ėý

The document discusses various types of dental cements, their compositions, properties, and uses. Dental cements are used as cavity linings, luting agents, and have been modified to be used as filling materials. The roles of dental cements include being protective, palliative, and therapeutic in endodontic treatment and restorations.1. IMPRESSION MATERIALS ELASTOMERIC.pptx

1. IMPRESSION MATERIALS ELASTOMERIC.pptxDr. Priyanshi Jaiswal

Ėý

This document discusses different types of impression materials used in dentistry. It describes elastomeric impression materials including polysulfides, condensation silicones, addition silicones, and polyethers. It provides details on the composition, chemistry, properties, advantages and disadvantages of each material. It also discusses impression trays, manipulation of impression materials, and removal of impressions.Dental Cements

Dental CementsDr. Arpit Viradiya

Ėý

This document summarizes three types of dental cements: zinc phosphate cement, zinc polycarboxylate cement, and zinc oxide eugenol cement. It describes the introduction, composition, setting reaction, properties, manipulation and applications of each cement. Zinc phosphate cement is the oldest luting cement and involves a reaction between zinc oxide and phosphoric acid. Zinc polycarboxylate cement bonds to tooth structure through a reaction between polyacrylic acid and calcium ions. Zinc oxide eugenol cement sets through a reaction between zinc oxide, water and eugenol, and has sedative properties making it the least irritating to dental pulps.Cements

Cementsaruncs92

Ėý

This document discusses various dental cements, their properties, uses, and applications. It focuses on zinc oxide eugenol cement and calcium hydroxide cement. Zinc oxide eugenol cement is widely used and has good biocompatibility but poor mechanical properties. Modifications have improved strength. Calcium hydroxide cement has high pH and promotes pulp healing when used as a liner or temporary filling. Both cements are soluble but help maintain pulp vitality due to their properties.More Related Content

What's hot (16)

Crane composite cleanroom

Crane composite cleanroomDutco Tennant LLC

Ėý

We at Dutco Tennant LLC supply the exceptional Hygienic FRP Wall Cladding range from CRANE Composites to the Middle East. They are the worldâs leading manufacturer of premium Hygienic Wall Cladding and Ceiling tiles made from FRP. Crane Composites FRP wall panels combine expertise in composite material science, process, and technology with a deep understanding of End-user needs to deliver innovative products that outperform traditional building material such as Ceramic, Paint, PVC wall cladding & Acrylic panels, metals and woods.

Cost Reduction In Heat Treatment, Hot Rolling and Hot Forging by the use of P...

Cost Reduction In Heat Treatment, Hot Rolling and Hot Forging by the use of P...Srikar Shenoy

Ėý

This presentation outlines an innovative concept to reduce cost in heat treatment, hot rolling and hot forging. Industrial case studies and photos are included.Gypsum and its products

Gypsum and its productsDr.shiva sai vemula

Ėý

The document provides an overview of gypsum and its products. It discusses the history, terminology, composition, properties, uses, and recent developments of gypsum. Specifically, it covers:

- The origins and various forms of natural gypsum.

- The terminology used to describe gypsum products like casts, dies, and models.

- The composition of gypsum products, including the main reactive ingredient (calcium sulfate hemihydrate), additives like accelerators and retarders, and coloring agents.

- The properties of gypsum, including the theories of setting reactions, stages of setting, setting expansion, and factors that affect setting time, strength, and water-powder ratio.Polymer Product Technical Datasheet Template

Polymer Product Technical Datasheet TemplateTDSmaker

Ėý

Here is a âPolymer Product Technical Datasheet Templateâ. TDSmaker offer you free Datasheet/ Specsheet/ Techsheet. Visit to ( https://www.tdsmaker.com ) to get start with free template.ZINC PHOSPHATE CEMENT

ZINC PHOSPHATE CEMENTLabeed Ahmed

Ėý

Zinc phosphate cement is an older luting cement that serves as a standard for comparison. It has low hardness and high solubility. When mixed, the powder and liquid undergo an exothermic reaction where zinc ions are released and react with aluminum and phosphoric acid to form a zinc aluminophosphate gel. It has good compressive strength but no chemical adhesion and can cause pulp irritation due to its initial low pH. The powder contains mainly zinc oxide and magnesium oxide while the liquid contains phosphoric acid, water, and aluminum.DENTAL PLASTER

DENTAL PLASTERAnubhav Sharma

Ėý

This document provides information about dental plaster, including:

- It thanks teachers who provided the opportunity to do a project on dental plaster, which helped with research.

- Dental plaster is calcium sulfate hemihydrate that is used to make molds and casts for dental prostheses and restorations.

- The setting reaction involves the hemihydrate dissolving in water and re-crystallizing as calcium sulfate dihydrate with the release of heat.

- Dental plaster must be properly mixed with water at the correct water-to-powder ratio to avoid porosity and ensure strength of the final cast.Both 2016 shanghai development of innovative ultra high temperature coatings ...

Both 2016 shanghai development of innovative ultra high temperature coatings ...Yuguo Cui

Ėý

This document discusses the development of innovative ultra-high temperature coatings for corrosion protection of industrial process vessels and piping. It describes how conventional epoxy coatings have limitations above 100°C and introduces next-generation hybrid coatings that can withstand temperatures over 180°C. Test results are presented showing these hybrid coatings passed autoclave testing at 180°C for 7 days with no blistering or softening, demonstrating their ability to provide long-term corrosion protection at high temperatures.Advancements in Ceramic Coating Technology for the Power Generation Industry ...

Advancements in Ceramic Coating Technology for the Power Generation Industry ...Aldrin Arquillano

Ėý

The document discusses advancements in ceramic coating technology for use in high-temperature industrial processes. Next-generation hybrid coatings are able to withstand temperatures above 200°C while providing excellent erosion and chemical resistance. These solvent-free coatings use inorganic chemistry based on silicon, which offers extreme thermal stability compared to traditional organic coatings that exhibit limited success above 100°C. The coating can withstand temperatures up to 265°C dry and 200°C wet, is highly wear resistant, and provides corrosion protection in acidic environments like those containing sulfuric acid.Industrial flooring

Industrial flooringsonali parashar

Ėý

This document provides information on various floor and wall coating products from LightDuty Floor& Wall Coatings. It describes multiple polyurethane, epoxy resin, and polyurethane floor coating systems that offer properties like chemical resistance, abrasion resistance, flexibility, slip resistance, and ease of cleaning. The coatings have a range of applications in industrial, commercial, and institutional settings depending on the specific product. Technical data on properties like bond strength, hardness, and permeability are also provided for each coating.Liqtro Ascella (Product Data Sheet)

Liqtro Ascella (Product Data Sheet)Eko Kiswanto

Ėý

LIQTRO ASCELLA is a water-miscible metal working fluid that produces a milky white emulsion when mixed with water. It can be safely used on ferrous and non-ferrous metals. The high oil content provides good machining performance and corrosion protection. It contains biocides to prolong the service life. The product is recommended at treat rates of 5-10% for general and difficult to machine materials and can be used as a 5% hydraulic fluid.Controlling decarburization during hot rolling of rail steel

Controlling decarburization during hot rolling of rail steelSrikar Shenoy

Ėý

Decarburization of steel during hot rolling makes the hot rolled products prone to low fatigue life. This is especially true in the case of hot rolled rail steel and automobile leaf springs. The presentation gives a practical technique to substantially reduce decarburisation and ensure uniform hardness of hot rolled steel. Prevention of welding / sticking of billets at high temperature, reduced scale pits on hot rolled material, reduced scaling and decarburisation due to billet over-heating in furnace and slightly increased yield are some of the other benefits enabled by use of this technique.Hydrocolloids

HydrocolloidsDrmumtaz Islam

Ėý

This document discusses reversible hydrocolloids, which are polysaccharide colloidal suspensions used for dental impressions. Reversible hydrocolloids exist as either a sol or gel, transitioning between the two states during the impression process. They are extracted from seaweeds and set via cooling and physical bonding. Examples include agar, which is supplied in tubes or syringes and sets in the mouth. Reversible hydrocolloids are dimensionally unstable due to water absorption and evaporation, but provide accurate impressions and are easy to use.White paper - investigating the effects of multiple re-use of Ti6Al4V powder ...

White paper - investigating the effects of multiple re-use of Ti6Al4V powder ...Lucy Grainger

Ėý

- The document investigates the effects of repeatedly re-using Ti6Al4V metal powder in additive manufacturing builds over 38 total builds using a Renishaw AM250 system.

- Analysis found a small but steady increase in oxygen and nitrogen levels in the powder as builds increased, with oxygen levels exceeding specifications after around 16 builds. However, nitrogen levels remained within specifications.

- Physical properties of the powder like particle size distribution and flow were also affected, but the changes were minor and not expected to impact the manufacturing process or part quality.

- It was concluded that repeatedly re-using the powder up to 38 times did not significantly alter the powder properties or composition enough to require powder disposal under normal manufacturing conditions.LACS Ceramic Coating Presentation (Shared File)

LACS Ceramic Coating Presentation (Shared File)Jeff Abshire

Ėý

Louisiana Advanced Coating Solutions provides proprietary ceramic coatings for industrial, automotive, aerospace, military, and other applications. Their coatings offer benefits such as corrosion and heat resistance from 500°F to over 2000°F, various thickness and color options, and increased performance and lifespan of coated parts and equipment. Key products include heat cured, high temperature, dry film lubricant, clear, heat dissipating, and NIR coatings. The company conducts thorough testing of coatings' durability, corrosion protection, hardness, flexibility, chemical resistance, adhesion, abrasion resistance, and thermal barrier properties per ASTM standards. Ceramic coatings can significantly increase equipment lifespan through reduced wear and maintenance needs.Weh61882 61886 high temperature resistance finish coat (200-600â) (all k...

Weh61882 61886 high temperature resistance finish coat (200-600â) (all k...GOPAL RAMALINGAM

Ėý

This document describes a high temperature resistant finish coat that can withstand temperatures between 200-600°C. It is available in various colors and grey. It has high temperature resistance and anti-corrosive properties. The coating has a double component formulation and can be applied by brushing, rolling, or spraying. It dries quickly and has strong adhesion. It provides corrosion protection for 3-5 years when applied in 2-3 coats to a thickness of 50-80um.Renishaw Ti6Al4V metal powder re-use study

Renishaw Ti6Al4V metal powder re-use studyLucy Grainger

Ėý

There are various issues and concerns surrounding the re-use of metal powders through metal powder bed processes. This presentation discusses some of these issues and presents the latest results of a powder re-use study, in which a single batch of Ti6Al4V alloy powder was used over 38 routine builds. Chemistry and physical properties of the powder were assessed over the period of the study as well as tensile properties of built test bars.Similar to Pipeseal data sheet (20)

Zinc oxide eugenol

Zinc oxide eugenolDr. Roshni Maurya

Ėý

Zinc oxide-eugenol (ZOE) is a dental cement that has been used for over 150 years. It is used for multiple applications including impressions, temporary fillings, root canal fillings, cementing, and surgical dressings. ZOE cement sets via a chemical reaction between zinc oxide and eugenol. It has low strength but is biocompatible. Modified versions with additions like EBA or polymers have improved properties but ZOE remains useful due to its favorable pulpal response and low cost.Durapatch

Durapatch Dale Stauffer

Ėý

âĒ All Purpose Quick Cure Epoxy Paste

âĒ Hardens in 5â 15 minutes depending on ambient temperature (down to 38°F)

âĒ Ideal for immediate field use repairs

âĒ Trowellable - ideal for vertical surface repairs

âĒ Self-priming - bonds chemically and mechanically to the substrate

âĒ Can be sanded, drilled, tapped and machined

âĒ 100% solids - No VOCsdental_cements.pdf

dental_cements.pdfssuser93f9e8

Ėý

The document discusses various types of dental cements, their compositions, properties, and uses. Dental cements are used as cavity linings, luting agents, and have been modified to be used as filling materials. The roles of dental cements include being protective, palliative, and therapeutic in endodontic treatment and restorations.1. IMPRESSION MATERIALS ELASTOMERIC.pptx

1. IMPRESSION MATERIALS ELASTOMERIC.pptxDr. Priyanshi Jaiswal

Ėý

This document discusses different types of impression materials used in dentistry. It describes elastomeric impression materials including polysulfides, condensation silicones, addition silicones, and polyethers. It provides details on the composition, chemistry, properties, advantages and disadvantages of each material. It also discusses impression trays, manipulation of impression materials, and removal of impressions.Dental Cements

Dental CementsDr. Arpit Viradiya

Ėý

This document summarizes three types of dental cements: zinc phosphate cement, zinc polycarboxylate cement, and zinc oxide eugenol cement. It describes the introduction, composition, setting reaction, properties, manipulation and applications of each cement. Zinc phosphate cement is the oldest luting cement and involves a reaction between zinc oxide and phosphoric acid. Zinc polycarboxylate cement bonds to tooth structure through a reaction between polyacrylic acid and calcium ions. Zinc oxide eugenol cement sets through a reaction between zinc oxide, water and eugenol, and has sedative properties making it the least irritating to dental pulps.Cements

Cementsaruncs92

Ėý

This document discusses various dental cements, their properties, uses, and applications. It focuses on zinc oxide eugenol cement and calcium hydroxide cement. Zinc oxide eugenol cement is widely used and has good biocompatibility but poor mechanical properties. Modifications have improved strength. Calcium hydroxide cement has high pH and promotes pulp healing when used as a liner or temporary filling. Both cements are soluble but help maintain pulp vitality due to their properties.Impression materials and recent advances.pptx

Impression materials and recent advances.pptxMuskan Agarwal

Ėý

The document discusses dental impression materials and recent advances. It defines a dental impression and describes the desirable properties of impression materials including biocompatibility, rheological properties, and mechanical and thermal properties. It covers various types of impression materials including alginate, elastomers like polysulfide, silicone, and polyether materials. Recent advances in alginate, silicone, and polyether impressions are discussed. The document also mentions digital imaging and intraoral scanning.Inelastic impression material

Inelastic impression material Aswati Soman

Ėý

This document discusses impression compound, which is a non-elastic, thermoplastic impression material. It comes in various colors (red, green, gray) which indicate different working temperatures. Red compound has a lower melting temperature. Impression compound is composed of thermoplastic resins, waxes, filler, and lubricants. It has high viscosity and mucocompressive properties. It is commonly used to make preliminary impressions for edentulous ridges and single crowns. Some techniques described are border molding, copper ring technique, and using impression plaster. Impression compound has advantages of being economical and easy to use but also has disadvantages like poor dimensional stability and difficulty recording fine details due to high viscosity.MRO Catalogue - 2016 (2) (1)

MRO Catalogue - 2016 (2) (1)Sanskruti Enterprises

Ėý

Pidilite Industries is an Indian company that has been a pioneer in consumer and specialty chemicals since 1959. It is the market leader in India for adhesives, sealants, construction chemicals, and polymers. The company's Fevicol brand of adhesives is one of the most trusted brands in India and the largest selling adhesives brand in Asia. Pidilite offers a wide range of products developed through in-house R&D including adhesives, construction chemicals, industrial adhesives, and more.Raising performance in sheet molding compounds (SMC) - Highlight

Raising performance in sheet molding compounds (SMC) - HighlightHuntsman Advanced Materials Europe

Ėý

This document summarizes an epoxy resin system for sheet molding compounds that provides high performance. The 4-component system offers easy processing, compatibility with carbon fibers, high glass transition temperature, and excellent mechanical properties. It can be formulated to adjust reactivity and provides robust performance and good adhesion to reinforcement fibers like carbon and glass. The starting formulation and recommended cure cycle are provided along with neat resin properties showing high modulus, strength and toughness.Impression Materials.....bajaj seminar.ppt

Impression Materials.....bajaj seminar.pptSheetal675612

Ėý

impression materials are one of the routinely used materials in dentistry for recording the oral anatomic structure for rehabilitation with prosthesis. luting cement

luting cementVincy Bernice

Ėý

This document provides information about various luting cements used in dentistry. It focuses on zinc phosphate cement, discussing its composition, setting reaction, properties and applications. The key points are:

1. Zinc phosphate cement is the oldest luting agent and consists of a powder made primarily of zinc oxide and a liquid of phosphoric acid. The acid reacts with zinc oxide to form zinc phosphate during setting.

2. It has a working time of 1.5-2 minutes and setting time of 2.5-8 minutes. Its compressive strength is 104MPa and it bonds mechanically rather than chemically.

3. Zinc phosphate cement is used for cementing permanent restorationsImpression materials for complete denture

Impression materials for complete dentureMarwan Ramadan,Dentist

Ėý

presentation about

indications ,contraindications ,and how to use some of these

impression materials for complete denture constructionDENTURE BASE RESINS

DENTURE BASE RESINS Dr Sumaya Saleem

Ėý

CONTENTS:

Introduction

History

Ideal requirements

Classification

Stages of polymerization

Manipulation

Properties of Denture Base Resins

Processing errors

Recent Advancements

Conclusion

References

New rich text document

New rich text documentSadiyahh Channa

Ėý

This document summarizes the properties and use of four different non-elastic impression materials: impression plaster, impression compound, impression waxes, and zinc oxide eugenol. Impression plaster is mixed with water or anti-expansion solution and sets in the mouth to create an impression. Impression compound is softened in warm water before seating in the mouth. Impression waxes are used to modify other impressions. Zinc oxide eugenol is a paste mixed in a 1:1 ratio and used in thin sections to take wash impressions. Each material has advantages like detail capture and disadvantages like dimensional stability.Universal Distributors Ltd: Alteco Adhesive Products

Universal Distributors Ltd: Alteco Adhesive ProductsMarcus Anselm

Ėý

Universal Distributors Ltd

exclusive distribution rights for Alteco Adhesive products in New Zealand and Australia

.Jaman

JamanKulwinder Tiwana

Ėý

Root canal sealers are used to seal the root canal system during root canal treatment. An ideal root canal sealer forms a tight seal, is radiopaque, adheres well to dentin, has adequate working and setting times, is insoluble and biocompatible. Common root canal sealers discussed in the document include Kerr's sealer, Grossman's sealer, Wach's paste, Tubliseal, chloropercha and Nogenol. Each sealer has advantages like sealing ability and disadvantages like potential toxicity if extruded beyond the root canal. The document provides details on the composition, properties and uses of different root canal sealers.recent advances in impression materials

recent advances in impression materialsramkoti reddy

Ėý

This document summarizes recent advances in dental impression materials. It discusses improvements made to alginate impression materials, including extended pour times, tray adhesives, reduced dust, and antimicrobial properties. It also describes advances in elastomeric materials like addition silicones, which provide highly accurate impressions with dimensional stability and short setting times. Digital impression systems offer advantages of speed and accuracy but also have limitations. Overall, the document outlines key properties desired in impression materials and new formulations that improve user experience and clinical outcomes.Irreversible dental materials

Irreversible dental materialsAshitha Dominic

Ėý

1. The document discusses various types of irreversible impression materials used in dentistry, including their properties and applications.

2. Impression materials are classified based on their setting mechanism (chemical reaction or temperature change) and elasticity (rigid, elastic). They are also classified based on their use (edentulous vs dentulous patients) and ability to displace tissues (mucostatic, mucocompressive).

3. Common irreversible impression materials discussed include zinc oxide eugenol, impression plaster, alginate, polysulfides, condensation silicone, addition silicone, and polyether. The properties, composition, advantages and disadvantages of each material are summarized.Raising performance in sheet molding compounds (SMC) - Highlight

Raising performance in sheet molding compounds (SMC) - HighlightHuntsman Advanced Materials Europe

Ėý

Pipeseal data sheet

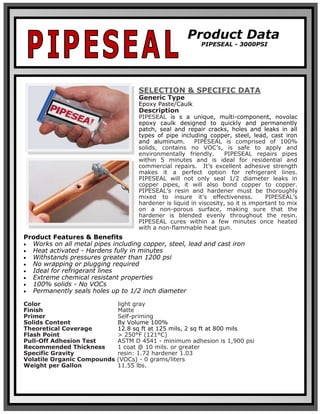

- 1. SELECTION & SPECIFIC DATA Generic Type Epoxy Paste/Caulk Description PIPESEAL is s a unique, multi-component, novolac epoxy caulk designed to quickly and permanently patch, seal and repair cracks, holes and leaks in all types of pipe including copper, steel, lead, cast iron and aluminum. PIPESEAL is comprised of 100% solids, contains no VOCâs, is safe to apply and environmentally friendly. PIPESEAL repairs pipes within 5 minutes and is ideal for residential and commercial repairs. Itâs excellent adhesive strength makes it a perfect option for refrigerant lines. PIPESEAL will not only seal 1/2 diameter leaks in copper pipes, it will also bond copper to copper. PIPESEALâs resin and hardener must be thoroughly mixed to insure itâs effectiveness. PIPESEALâs hardener is liquid in viscosity, so it is important to mix on a non-porous surface, making sure that the hardener is blended evenly throughout the resin. PIPESEAL cures within a few minutes once heated with a non-flammable heat gun. Product Features & Benefits âĒ Works on all metal pipes including copper, steel, lead and cast iron âĒ Heat activated - Hardens fully in minutes âĒ Withstands pressures greater than 1200 psi âĒ No wrapping or plugging required âĒ Ideal for refrigerant lines âĒ Extreme chemical resistant properties âĒ 100% solids - No VOCs âĒ Permanently seals holes up to 1/2 inch diameter Color light gray Finish Matte Primer Self-priming Solids Content By Volume 100% Theoretical Coverage 12.8 sq ft at 125 mils, 2 sq ft at 800 mils Flash Point > 250°F (121°C) Pull-Off Adhesion Test ASTM D 4541 - minimum adhesion is 1,900 psi Recommended Thickness 1 coat @ 10 mils. or greater Specific Gravity resin: 1.72 hardener 1.03 Volatile Organic Compounds (VOCs) - 0 grams/liters Weight per Gallon 11.55 lbs. Product Data PIPESEAL - 3000PSI

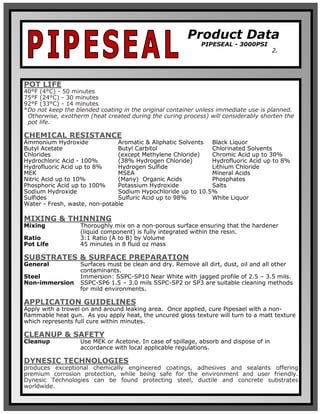

- 2. Product Data PIPESEAL - 3000PSI 2. POT LIFE 40°F (4°C) - 50 minutes 75°F (24°C) - 30 minutes 92°F (33°C) - 14 minutes *Do not keep the blended coating in the original container unless immediate use is planned. Otherwise, exotherm (heat created during the curing process) will considerably shorten the pot life. CHEMICAL RESISTANCE Ammonium Hydroxide Aromatic & Aliphatic Solvents Black Liquor Butyl Acetate Butyl Carbitol Chlorinated Solvents Chlorides (except Methylene Chloride) Chromic Acid up to 30% Hydrochloric Acid - 100% (38% Hydrogen Chloride) Hydrofluoric Acid up to 8% Hydrofluoric Acid up to 8% Hydrogen Sulfide Lithium Chloride MEK MSEA Mineral Acids Nitric Acid up to 10% (Many) Organic Acids Phosphates Phosphoric Acid up to 100% Potassium Hydroxide Salts Sodium Hydroxide Sodium Hypochloride up to 10.5% Sulfides Sulfuric Acid up to 98% White Liquor Water - Fresh, waste, non-potable MIXING & THINNING Mixing Thoroughly mix on a non-porous surface ensuring that the hardener (liquid component) is fully integrated within the resin. Ratio 3:1 Ratio (A to B) by Volume Pot Life 45 minutes in 8 fluid oz mass SUBSTRATES & SURFACE PREPARATION General Surfaces must be clean and dry. Remove all dirt, dust, oil and all other contaminants. Steel Immersion: SSPC-SP10 Near White with jagged profile of 2.5 â 3.5 mils. Non-immersion SSPC-SP6 1.5 â 3.0 mils SSPC-SP2 or SP3 are suitable cleaning methods for mild environments. APPLICATION GUIDELINES Apply with a trowel on and around leaking area. Once applied, cure Pipesael with a non- flammable heat gun. As you apply heat, the uncured gloss texture will turn to a matt texture which represents full cure within minutes. CLEANUP & SAFETY Cleanup Use MEK or Acetone. In case of spillage, absorb and dispose of in accordance with local applicable regulations. DYNESIC TECHNOLOGIES produces exceptional chemically engineered coatings, adhesives and sealants offering premium corrosion protection, while being safe for the environment and user friendly. Dynesic Technologies can be found protecting steel, ductile and concrete substrates worldwide.

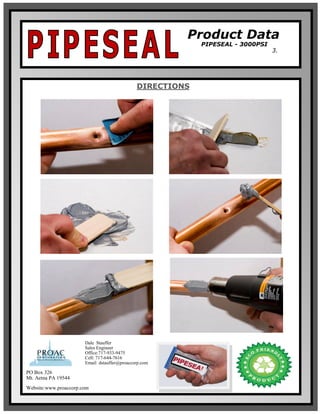

- 3. Product Data PIPESEAL - 3000PSI 3. DIRECTIONS PO Box 326 Mt. Aetna PA 19544 Website:www.proaccorp.com Dale Stauffer Sales Engineer Office:717-933-9475 Cell: 717-644-7616 Email: dstauffer@proaccorp.com