pneumatics and control mechanical enggn

Download as PPTX, PDF0 likes18 views

Pneumatics

1 of 13

Download to read offline

Recommended

19BT02004.pptx

19BT02004.pptxDevenGohel1

╠²

Pneumatics uses compressed air or gas to power machines. A central compressor powers pneumatic devices like cylinders, actuators and tools. Pneumatic systems are commonly used in factories and construction sites. They have advantages over electric motors in being more flexible, safer in hazardous environments, and sometimes cheaper. While pneumatics is simpler than hydraulics, hydraulics can move higher loads and provide more force due to using relatively incompressible liquid under high pressure. Common industrial pneumatic pressures are 80-100 psi, while hydraulics uses 1000-5000 psi or more.Pneumatic control

Pneumatic controldfarouq

╠²

Pneumatics uses compressed air to perform mechanical operations and motions like linear, swivel, and rotary motion. Common industrial applications of pneumatics include material handling, packaging, filling, sorting, and machining operations like drilling and milling. The pneumatic cylinder is a key component that provides linear motion and is widely used due to its low cost, ease of installation, and availability in various sizes and strokes. Pneumatics offer advantages like insensitivity to temperature fluctuations, ability to store and transport compressed air, high speeds, simple and inexpensive components, and lack of risk of explosion. However, pneumatics also have disadvantages like noise from exhaust air and limited force capability compared to other technologies.Fabrication of pneumatic forging(2)

Fabrication of pneumatic forging(2)Abhinav kumar

╠²

The Pneumatics is study of mechanical motion caused by pressurized gases and how this motion can be used to perform engineering tasks.

Pneumatic systems operate on a supply of compressed air which must be available in sufficient quantity and the air used in pneumatic devices is dried and free from moisture so that it does not create any problem to the internal parts of the system and avoid corrosive actions too.

The compressed air is delivered by the compressor which is a machine that takes in air or gas at a certain pressure and delivered the air at a high pressure.

This machine is pneumatic powered machine and electrical energy is used to operate which has low co-efficient of friction and air.

This machine is designed in solid-works software (module 2017). Chapter 1 introduction to pneumatic

Chapter 1 introduction to pneumaticTaj Nesha

╠²

This chapter introduces Basics of Pneumatics, Advantages & Disadvantages, Application and symbols to students who are taking Pneumatics and Hydraulics course in PolytechnicsPneumatic.pptx

Pneumatic.pptxRayanSajib1

╠²

Pneumatic conveying uses compressed air to transport granular and powder materials through closed pipelines. There are two main types: dilute phase conveying for shorter distances up to 300m, and dense phase conveying for longer distances over 500m. Pneumatic conveying systems consist of a blower/compressor, feeding device, filter, pipeline, and receiving hopper. The compressed air carries materials through the pipeline to be separated from the air stream and collected at the destination. Pneumatic conveying is widely used in manufacturing and processing industries due to its effectiveness, cost efficiency, and flexibility.AUTOMATIC PNEUMATIC INTERNAL PIPE SCRAP REMOVING MACHINE2.pptx

AUTOMATIC PNEUMATIC INTERNAL PIPE SCRAP REMOVING MACHINE2.pptxVishahanVenthan

╠²

The document describes the design of an automatic pneumatic internal pipe scrap removing machine. It uses compressed air to power a pneumatic cylinder with a round file attached, which is used to remove scraps from the inside of pipes. The machine aims to increase efficiency and accuracy by reducing human involvement in the scrap removal process. It works by using compressed air to power the forward and backward stroke of the cylinder and file, which removes pipe scraps automatically. This provides a faster, more consistent method of internal pipe scrap removal compared to manual methods.ilide.info-chapter-1-pneumatic-overview-2020-pr_f7325d006b523d9677a7d22519f0fddd

ilide.info-chapter-1-pneumatic-overview-2020-pr_f7325d006b523d9677a7d22519f0fdddSangNh7

╠²

This document discusses low cost automation using pneumatic systemsBENEFITS OF INDUSTRIAL CENTRIFUGAL PROCESS FANS

BENEFITS OF INDUSTRIAL CENTRIFUGAL PROCESS FANSNeelRao

╠²

Centrifugal fans are one of the vital devices used to provide the specific flow of air for combustion air, exhaust air, cooling, ventilation, and other uses in industrial settings. These equipment are noted for their reliability, adaptability, decent lifespan, and workability in harsh environments requiring little maintenance.

AerofilmSystems Brochure_DIG

AerofilmSystems Brochure_DIGDanielle van de Schoot

╠²

This document provides an overview of air caster transportation systems produced by Aerofilm Systems. It describes various air caster products such as permanently installed air caster systems, modular air caster systems, air casters, lift cushions, and custom engineered solutions. The main benefits of air caster transportation systems are listed as being ergonomic, causing no floor damage, suitable for heavy loads, friction-free movement, low maintenance, and accurate positioning.AerofilmSystems Brochure_DIG

AerofilmSystems Brochure_DIGJacco Driessen

╠²

This document provides an overview of air caster transportation systems produced by Aerofilm Systems. It describes various air caster products such as permanently installed air caster systems, modular air caster systems, air casters, lift cushions, and custom engineered solutions. The main benefits of air caster transportation systems are listed as being ergonomic with low effort required, suitable for heavy loads, friction-free movement, accurate positioning, and applicable in cleanroom environments.AerofilmSystems Brochure_DIG

AerofilmSystems Brochure_DIGStephan de Rooij

╠²

This document provides an overview of air caster transportation systems produced by Aerofilm Systems. It describes various air caster products such as permanently installed air caster systems, modular air caster systems, air casters, lift cushions, and custom engineered solutions. The main benefits of air caster transportation systems are listed as being ergonomic, causing no floor damage, suitable for heavy loads, friction-free movement, low maintenance, and accurate positioning.Pneumatics & Hydraulics

Pneumatics & HydraulicsJHALAKNIHALANI

╠²

This document discusses pneumatic systems and their components. It covers the basics of pneumatic systems including common components like compressors, filters, dryers, receivers, control valves and actuators. It also discusses the gases used, advantages and disadvantages of pneumatic systems, applications, electro-pneumatic controllers and system diagrams. Hydraulic systems are mentioned but not described in detail.Pneumatics and hydraulics ppt

Pneumatics and hydraulics pptwifi0047

╠²

This document provides an overview of hydraulics and pneumatics systems. It defines the terms, explains basic concepts like Pascal's law and fluid power transmission. It describes the working principles of hydraulic and pneumatic systems, including components like pumps, valves, actuators. Examples of applications in various industries like manufacturing, automobiles are given. The advantages and disadvantages of both systems are listed. Overall it serves as a introductory guide to the fundamentals and applications of hydraulics and pneumatics.Fabrication of Semi-Automatic Molten Metal Pouring System in Casting Industries.

Fabrication of Semi-Automatic Molten Metal Pouring System in Casting Industries.IJERA Editor

╠²

This document summarizes the fabrication of a semi-automatic molten metal pouring system for casting industries. It aims to introduce an automated pneumatic system for transferring molten metal from an electrical furnace to a die casting, reducing manual labor and hazards. The key components of the system include an air compressor, pneumatic cylinder, flow control valves, hand level valve, hoses, motion transfer mechanism, and trolley. When operated, compressed air moves the piston to lift a bowl of molten metal from the furnace to the die casting mold. The study concludes this system minimizes manual work and travel time compared to conventional manual pouring methods.295790559-Compressed-Air-Production-Using-Vehicle-Suspension.pptx

295790559-Compressed-Air-Production-Using-Vehicle-Suspension.pptxJeevanLandgePatil

╠²

This document provides information about using vehicle suspension to produce compressed air. It discusses the objectives, main components, working principle and applications of the system. The key components are a pneumatic cylinder, quick exhaust valve, spring arrangement, and air collecting tank. When the vehicle encounters irregular roads, the up and down motion of the wheels is converted into compressed air energy using these components. The compressed air is stored in a tank and can be used to power pneumatic applications. Some potential applications mentioned include using the system on speed bumps to collect air and filling tires with compressed air on commercial vehicles.Automation 4.0

Automation 4.0UJJAWALCHAUHAN6

╠²

Pneumatic systems use compressed air to achieve low-cost automation in industries. They are widely used by small and medium enterprises to reduce costs through decreasing machine investment, process time, and increasing productivity and quality consistency. Pneumatics offer simple and easy control through pneumatic components like cylinders, valves, and regulators. Common applications include pushing, pulling, lifting, feeding, clamping, and pressing operations in manufacturing assembly lines, packaging, bottling, vehicle cleaning, and more. While pneumatic systems are lighter and easier to control than hydraulics, they typically operate at lower pressures of 5-10 bar.Three axis pneumatic modern trailer

Three axis pneumatic modern trailer1apr1991

╠²

The document discusses automation in automobiles and the role of hydraulics. It then provides an overview of pneumatics, including how compressed air is produced using reciprocating compressors. Key factors in pneumatic system design are discussed such as selection of pneumatics, production of compressed air, and types of positive displacement compressors. Subsequent chapters cover material selection factors and major components of a pneumatic three-axis tipper system, including air compressors.DOC-20231007-WA0000.pptxndjdjdjsjsjshshshshns

DOC-20231007-WA0000.pptxndjdjdjsjsjshshshshns2750KaifBudye

╠²

The document summarizes the design and fabrication of a pneumatic vice for a mechanical engineering workshop microproject. It describes the working principles of pneumatics using compressed air. The main components of the pneumatic vice are identified as the compressor, direction control valve, flow control valve, and double acting cylinder. Advantages of pneumatic systems are highlighted as high efficiency due to reusable compressed air, longevity and dependability of pneumatic components.Fabrication of solar operated pneumatic reciprocating water pumping system

Fabrication of solar operated pneumatic reciprocating water pumping systemEcway Technologies

╠²

This document provides a summary of a project report on the fabrication of a solar-operated pneumatic reciprocating water pumping system. The report includes chapters on the description of equipment used like pneumatic cylinders, solenoid valves, air compressors, and control units. It also covers the design, working principle, applications, materials list, and cost estimation of the system. The goal of the project is to pump water using minimal electric power generated from solar panels.Et0077 fabrication of solar operated pneumatic reciprocating water pumping ...

Et0077 fabrication of solar operated pneumatic reciprocating water pumping ...Ecway Technologies

╠²

This document appears to be a project report for the fabrication of a solar operated pneumatic reciprocating water pumping system. It includes chapters that describe the equipment used like the pneumatic cylinder, solenoid valves, air compressor, and control unit. It discusses the design, working principle, applications, materials list, and cost estimation. The objective is to pump water using minimal electric power generated from solar panels. Pneumatics is selected due to its simplicity and economy for automation. Compressed air is produced using a reciprocating air compressor.Et0077 fabrication of solar operated pneumatic reciprocating water pumping ...

Et0077 fabrication of solar operated pneumatic reciprocating water pumping ...Ecwaytech

╠²

This document provides a summary of a project report on the fabrication of a solar-operated pneumatic reciprocating water pumping system. The report includes chapters on the description of equipment used like pneumatic cylinders, solenoid valves, air compressors, and control units. It also covers the design, working principle, applications, materials list, and cost estimation of the system. The goal of the project is to pump water using minimal electric power generated from solar panels.Fabrication of solar operated pneumatic reciprocating water pumping system

Fabrication of solar operated pneumatic reciprocating water pumping systemEcway Technologies

╠²

This document appears to be a project report for the fabrication of a solar operated pneumatic reciprocating water pumping system. It includes chapters that describe the equipment used like the pneumatic cylinder, solenoid valves, air compressor, and control unit. It discusses the design, working principle, applications, materials list, and cost estimation. The objective is to pump water using minimal electric power generated from solar panels. Pneumatics is selected due to its simplicity and economy for automation. Compressed air is produced using a reciprocating compressor and then used to power the pneumatic cylinder for reciprocating motion to pump water.FABRICATION OF PNEUMATIC CONTROLLED RAMMER STRIKER FOR MOULDING PROCES.pptx

FABRICATION OF PNEUMATIC CONTROLLED RAMMER STRIKER FOR MOULDING PROCES.pptxchockalingam athilingam

╠²

This document provides details on the fabrication of a pneumatic controlled rammer striker for moulding processes. It includes an introduction describing the role of project work in technical education. It then provides a synopsis of the project, which is to develop a ramming mechanism using a double acting cylinder controlled by a solenoid valve to increase productivity while overcoming labor shortages. Construction details, the working principle, and applications are described. Diagrams of pneumatic components and circuits are also included.Three axis modern tipper

Three axis modern tipperApurv Amit

╠²

This document presents a project on a three axis modern tipper. It discusses the major parts of the tipper including the air compressor, direction control valve, air tank, and cylinders. It explains how pneumatics are used, including the production of compressed air and the principle of operation. Advantages include low cost, easy maintenance and handling, while disadvantages include higher initial cost and need for separate air supply. Applications include material unloading where space is limited.Indian Soil Classification System in Geotechnical Engineering

Indian Soil Classification System in Geotechnical EngineeringRajani Vyawahare

╠²

This PowerPoint presentation provides a comprehensive overview of the Indian Soil Classification System, widely used in geotechnical engineering for identifying and categorizing soils based on their properties. It covers essential aspects such as particle size distribution, sieve analysis, and Atterberg consistency limits, which play a crucial role in determining soil behavior for construction and foundation design. The presentation explains the classification of soil based on particle size, including gravel, sand, silt, and clay, and details the sieve analysis experiment used to determine grain size distribution. Additionally, it explores the Atterberg consistency limits, such as the liquid limit, plastic limit, and shrinkage limit, along with a plasticity chart to assess soil plasticity and its impact on engineering applications. Furthermore, it discusses the Indian Standard Soil Classification (IS 1498:1970) and its significance in construction, along with a comparison to the Unified Soil Classification System (USCS). With detailed explanations, graphs, charts, and practical applications, this presentation serves as a valuable resource for students, civil engineers, and researchers in the field of geotechnical engineering. More Related Content

Similar to pneumatics and control mechanical enggn (20)

ilide.info-chapter-1-pneumatic-overview-2020-pr_f7325d006b523d9677a7d22519f0fddd

ilide.info-chapter-1-pneumatic-overview-2020-pr_f7325d006b523d9677a7d22519f0fdddSangNh7

╠²

This document discusses low cost automation using pneumatic systemsBENEFITS OF INDUSTRIAL CENTRIFUGAL PROCESS FANS

BENEFITS OF INDUSTRIAL CENTRIFUGAL PROCESS FANSNeelRao

╠²

Centrifugal fans are one of the vital devices used to provide the specific flow of air for combustion air, exhaust air, cooling, ventilation, and other uses in industrial settings. These equipment are noted for their reliability, adaptability, decent lifespan, and workability in harsh environments requiring little maintenance.

AerofilmSystems Brochure_DIG

AerofilmSystems Brochure_DIGDanielle van de Schoot

╠²

This document provides an overview of air caster transportation systems produced by Aerofilm Systems. It describes various air caster products such as permanently installed air caster systems, modular air caster systems, air casters, lift cushions, and custom engineered solutions. The main benefits of air caster transportation systems are listed as being ergonomic, causing no floor damage, suitable for heavy loads, friction-free movement, low maintenance, and accurate positioning.AerofilmSystems Brochure_DIG

AerofilmSystems Brochure_DIGJacco Driessen

╠²

This document provides an overview of air caster transportation systems produced by Aerofilm Systems. It describes various air caster products such as permanently installed air caster systems, modular air caster systems, air casters, lift cushions, and custom engineered solutions. The main benefits of air caster transportation systems are listed as being ergonomic with low effort required, suitable for heavy loads, friction-free movement, accurate positioning, and applicable in cleanroom environments.AerofilmSystems Brochure_DIG

AerofilmSystems Brochure_DIGStephan de Rooij

╠²

This document provides an overview of air caster transportation systems produced by Aerofilm Systems. It describes various air caster products such as permanently installed air caster systems, modular air caster systems, air casters, lift cushions, and custom engineered solutions. The main benefits of air caster transportation systems are listed as being ergonomic, causing no floor damage, suitable for heavy loads, friction-free movement, low maintenance, and accurate positioning.Pneumatics & Hydraulics

Pneumatics & HydraulicsJHALAKNIHALANI

╠²

This document discusses pneumatic systems and their components. It covers the basics of pneumatic systems including common components like compressors, filters, dryers, receivers, control valves and actuators. It also discusses the gases used, advantages and disadvantages of pneumatic systems, applications, electro-pneumatic controllers and system diagrams. Hydraulic systems are mentioned but not described in detail.Pneumatics and hydraulics ppt

Pneumatics and hydraulics pptwifi0047

╠²

This document provides an overview of hydraulics and pneumatics systems. It defines the terms, explains basic concepts like Pascal's law and fluid power transmission. It describes the working principles of hydraulic and pneumatic systems, including components like pumps, valves, actuators. Examples of applications in various industries like manufacturing, automobiles are given. The advantages and disadvantages of both systems are listed. Overall it serves as a introductory guide to the fundamentals and applications of hydraulics and pneumatics.Fabrication of Semi-Automatic Molten Metal Pouring System in Casting Industries.

Fabrication of Semi-Automatic Molten Metal Pouring System in Casting Industries.IJERA Editor

╠²

This document summarizes the fabrication of a semi-automatic molten metal pouring system for casting industries. It aims to introduce an automated pneumatic system for transferring molten metal from an electrical furnace to a die casting, reducing manual labor and hazards. The key components of the system include an air compressor, pneumatic cylinder, flow control valves, hand level valve, hoses, motion transfer mechanism, and trolley. When operated, compressed air moves the piston to lift a bowl of molten metal from the furnace to the die casting mold. The study concludes this system minimizes manual work and travel time compared to conventional manual pouring methods.295790559-Compressed-Air-Production-Using-Vehicle-Suspension.pptx

295790559-Compressed-Air-Production-Using-Vehicle-Suspension.pptxJeevanLandgePatil

╠²

This document provides information about using vehicle suspension to produce compressed air. It discusses the objectives, main components, working principle and applications of the system. The key components are a pneumatic cylinder, quick exhaust valve, spring arrangement, and air collecting tank. When the vehicle encounters irregular roads, the up and down motion of the wheels is converted into compressed air energy using these components. The compressed air is stored in a tank and can be used to power pneumatic applications. Some potential applications mentioned include using the system on speed bumps to collect air and filling tires with compressed air on commercial vehicles.Automation 4.0

Automation 4.0UJJAWALCHAUHAN6

╠²

Pneumatic systems use compressed air to achieve low-cost automation in industries. They are widely used by small and medium enterprises to reduce costs through decreasing machine investment, process time, and increasing productivity and quality consistency. Pneumatics offer simple and easy control through pneumatic components like cylinders, valves, and regulators. Common applications include pushing, pulling, lifting, feeding, clamping, and pressing operations in manufacturing assembly lines, packaging, bottling, vehicle cleaning, and more. While pneumatic systems are lighter and easier to control than hydraulics, they typically operate at lower pressures of 5-10 bar.Three axis pneumatic modern trailer

Three axis pneumatic modern trailer1apr1991

╠²

The document discusses automation in automobiles and the role of hydraulics. It then provides an overview of pneumatics, including how compressed air is produced using reciprocating compressors. Key factors in pneumatic system design are discussed such as selection of pneumatics, production of compressed air, and types of positive displacement compressors. Subsequent chapters cover material selection factors and major components of a pneumatic three-axis tipper system, including air compressors.DOC-20231007-WA0000.pptxndjdjdjsjsjshshshshns

DOC-20231007-WA0000.pptxndjdjdjsjsjshshshshns2750KaifBudye

╠²

The document summarizes the design and fabrication of a pneumatic vice for a mechanical engineering workshop microproject. It describes the working principles of pneumatics using compressed air. The main components of the pneumatic vice are identified as the compressor, direction control valve, flow control valve, and double acting cylinder. Advantages of pneumatic systems are highlighted as high efficiency due to reusable compressed air, longevity and dependability of pneumatic components.Fabrication of solar operated pneumatic reciprocating water pumping system

Fabrication of solar operated pneumatic reciprocating water pumping systemEcway Technologies

╠²

This document provides a summary of a project report on the fabrication of a solar-operated pneumatic reciprocating water pumping system. The report includes chapters on the description of equipment used like pneumatic cylinders, solenoid valves, air compressors, and control units. It also covers the design, working principle, applications, materials list, and cost estimation of the system. The goal of the project is to pump water using minimal electric power generated from solar panels.Et0077 fabrication of solar operated pneumatic reciprocating water pumping ...

Et0077 fabrication of solar operated pneumatic reciprocating water pumping ...Ecway Technologies

╠²

This document appears to be a project report for the fabrication of a solar operated pneumatic reciprocating water pumping system. It includes chapters that describe the equipment used like the pneumatic cylinder, solenoid valves, air compressor, and control unit. It discusses the design, working principle, applications, materials list, and cost estimation. The objective is to pump water using minimal electric power generated from solar panels. Pneumatics is selected due to its simplicity and economy for automation. Compressed air is produced using a reciprocating air compressor.Et0077 fabrication of solar operated pneumatic reciprocating water pumping ...

Et0077 fabrication of solar operated pneumatic reciprocating water pumping ...Ecwaytech

╠²

This document provides a summary of a project report on the fabrication of a solar-operated pneumatic reciprocating water pumping system. The report includes chapters on the description of equipment used like pneumatic cylinders, solenoid valves, air compressors, and control units. It also covers the design, working principle, applications, materials list, and cost estimation of the system. The goal of the project is to pump water using minimal electric power generated from solar panels.Fabrication of solar operated pneumatic reciprocating water pumping system

Fabrication of solar operated pneumatic reciprocating water pumping systemEcway Technologies

╠²

This document appears to be a project report for the fabrication of a solar operated pneumatic reciprocating water pumping system. It includes chapters that describe the equipment used like the pneumatic cylinder, solenoid valves, air compressor, and control unit. It discusses the design, working principle, applications, materials list, and cost estimation. The objective is to pump water using minimal electric power generated from solar panels. Pneumatics is selected due to its simplicity and economy for automation. Compressed air is produced using a reciprocating compressor and then used to power the pneumatic cylinder for reciprocating motion to pump water.FABRICATION OF PNEUMATIC CONTROLLED RAMMER STRIKER FOR MOULDING PROCES.pptx

FABRICATION OF PNEUMATIC CONTROLLED RAMMER STRIKER FOR MOULDING PROCES.pptxchockalingam athilingam

╠²

This document provides details on the fabrication of a pneumatic controlled rammer striker for moulding processes. It includes an introduction describing the role of project work in technical education. It then provides a synopsis of the project, which is to develop a ramming mechanism using a double acting cylinder controlled by a solenoid valve to increase productivity while overcoming labor shortages. Construction details, the working principle, and applications are described. Diagrams of pneumatic components and circuits are also included.Three axis modern tipper

Three axis modern tipperApurv Amit

╠²

This document presents a project on a three axis modern tipper. It discusses the major parts of the tipper including the air compressor, direction control valve, air tank, and cylinders. It explains how pneumatics are used, including the production of compressed air and the principle of operation. Advantages include low cost, easy maintenance and handling, while disadvantages include higher initial cost and need for separate air supply. Applications include material unloading where space is limited.FABRICATION OF PNEUMATIC CONTROLLED RAMMER STRIKER FOR MOULDING PROCES.pptx

FABRICATION OF PNEUMATIC CONTROLLED RAMMER STRIKER FOR MOULDING PROCES.pptxchockalingam athilingam

╠²

Recently uploaded (20)

Indian Soil Classification System in Geotechnical Engineering

Indian Soil Classification System in Geotechnical EngineeringRajani Vyawahare

╠²

This PowerPoint presentation provides a comprehensive overview of the Indian Soil Classification System, widely used in geotechnical engineering for identifying and categorizing soils based on their properties. It covers essential aspects such as particle size distribution, sieve analysis, and Atterberg consistency limits, which play a crucial role in determining soil behavior for construction and foundation design. The presentation explains the classification of soil based on particle size, including gravel, sand, silt, and clay, and details the sieve analysis experiment used to determine grain size distribution. Additionally, it explores the Atterberg consistency limits, such as the liquid limit, plastic limit, and shrinkage limit, along with a plasticity chart to assess soil plasticity and its impact on engineering applications. Furthermore, it discusses the Indian Standard Soil Classification (IS 1498:1970) and its significance in construction, along with a comparison to the Unified Soil Classification System (USCS). With detailed explanations, graphs, charts, and practical applications, this presentation serves as a valuable resource for students, civil engineers, and researchers in the field of geotechnical engineering. 15. Smart Cities Big Data, Civic Hackers, and the Quest for a New Utopia.pdf

15. Smart Cities Big Data, Civic Hackers, and the Quest for a New Utopia.pdfNgocThang9

╠²

Smart Cities Big Data, Civic Hackers, and the Quest for a New UtopiaIntroduction to Safety, Health & Environment

Introduction to Safety, Health & Environmentssuserc606c7

╠²

Introduction to

Safety, Health &EnvironmentG8 mini project for alcohol detection and engine lock system with GPS tracki...

G8 mini project for alcohol detection and engine lock system with GPS tracki...sahillanjewar294

╠²

b.tech final year projects report for cseEnv and Water Supply Engg._Dr. Hasan.pdf

Env and Water Supply Engg._Dr. Hasan.pdfMahmudHasan747870

╠²

Core course, namely Environment and Water Supply Engineering. Full lecture notes are in book format for the BSc in Civil Engineering program. Engineering at Lovely Professional University (LPU).pdf

Engineering at Lovely Professional University (LPU).pdfSona

╠²

LPUŌĆÖs engineering programs provide students with the skills and knowledge to excel in the rapidly evolving tech industry, ensuring a bright and successful future. With world-class infrastructure, top-tier placements, and global exposure, LPU stands as a premier destination for aspiring engineers.Frankfurt University of Applied Science urkunde

Frankfurt University of Applied Science urkundeLisa Emerson

╠²

Duplicate Frankfurt University of Applied Science urkunde, make a Frankfurt UAS degree.Soil Properties and Methods of Determination

Soil Properties and Methods of DeterminationRajani Vyawahare

╠²

This PPT covers the index and engineering properties of soil. It includes details on index properties, along with their methods of determination. Various important terms related to soil behavior are explained in detail. The presentation also outlines the experimental procedures for determining soil properties such as water content, specific gravity, plastic limit, and liquid limit, along with the necessary calculations and graph plotting. Additionally, it provides insights to understand the importance of these properties in geotechnical engineering applications.How to Make an RFID Door Lock System using Arduino

How to Make an RFID Door Lock System using ArduinoCircuitDigest

╠²

Learn how to build an RFID-based door lock system using Arduino to enhance security with contactless access control.IPC-9716_2024 Requirements for Automated Optical Inspection (AOI) Process Con...

IPC-9716_2024 Requirements for Automated Optical Inspection (AOI) Process Con...ssuserd9338b

╠²

IPC-9716_2024 Requirements for Automated Optical Inspection (AOI) Process Control for Printed Board Assemblies.pdfpneumatics and control mechanical enggn

- 1. pneumatics Presented by :- Vikash Kumar

- 2. introduction The word Pneumatics is derived from a Greek word Pneumatikos --- ŌĆ£pneumaŌĆØ- means ŌĆ£windŌĆØ ŌĆ£ tikos ŌĆØ ŌĆō means ŌĆ£ science ŌĆØ Pneumatics is the name given to the branch of science which deals with the properties, motion and behavior of air.

- 3. ŌĆó Pneumatics deals the use of compressed air or gases . Most commonly, compressed air is used to do mechanical work that is to produce motion and generate forces. Pneumatic system have the task of converting the energy stored in compressed air into motion. ŌĆó Cylinders are most commonly used in pneumatic system. They are characterized by robust construction, large range of types, simple installation and favorable performance. As a result of these benefits, pneumatics is used in a wide range of application. Detailed introduction

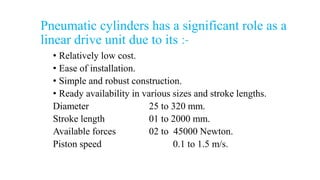

- 4. Pneumatic cylinders has a significant role as a linear drive unit due to its :- ŌĆó Relatively low cost. ŌĆó Ease of installation. ŌĆó Simple and robust construction. ŌĆó Ready availability in various sizes and stroke lengths. Diameter 25 to 320 mm. Stroke length 01 to 2000 mm. Available forces 02 to 45000 Newton. Piston speed 0.1 to 1.5 m/s.

- 5. Pneumatic components can perform ŌĆó Linear motion ŌĆó Swivel motion ŌĆó Rotary motion

- 6. Are a of application ŌĆó Spray painting ŌĆó Crop spraying and operation of other agricultural equipment ŌĆó Pneumatic robots ŌĆó Machine tool, work or tool feeding ŌĆó Bottling and filling machines ŌĆó Operation of heavy or hot doors ŌĆó Dental drills ŌĆó and so much moreŌĆ” new applications are developed daily

- 7. Some industrial application employing pneumatics are listed below :- ŌĆó General methods of material handling ŌĆō 1. Clamping 2. Shifting 3. Positioning 4. Orienting ŌĆó General Applications ŌĆō 1. Packaging 2. Filling 3. Locking 4. Driving axes. 5. Door control 6. Transfer of material 7. Stacking of components 8. stamping

- 8. Compressed air preparation Compressed air consumption

- 9. Advantages and distinguishing characteristic of compressed air- ’āśAvailability ’āśTransport ’āśstorage ’āśTemperature ’āśExplosion proof ’āśAir is available practically everywhere in unlimited quantity ’āśAir can be easily transported in pipelines, over large distances. ’āśCompressed air can be stored in a reservoir and removed as required. In addition the reservoir can be transportable. ’āśCompressed air is relatively insensitive to temperature. ’āśCompressed air offers no risk of explosion or fire.

- 10. ’āśCleanliness ’āśComponents ’āśSpeed ’āśOverload safe ’āśUnlubricated exhaust is clean. ’āśThe operating components are of simple construction and therefore inexpensive. ’āśCompressed air is very fast working medium. ’āśPneumatic tools and operating components can be loaded to the point of stopping.

- 11. Pneumatics Symbols - Supply units Service equipment's

- 12. Combined symbols Filter regulator and lubricator (FRL) Simplified diagram of service unit

- 13. Simplified air service unit without lubricator Pressure regulator relieving type

![group CC [Autosaved].pptx in the field of engineering](https://cdn.slidesharecdn.com/ss_thumbnails/groupccautosaved-240502141157-4acbc85b-thumbnail.jpg?width=560&fit=bounds)