Plastic and Polymers

- 1. INTRODUCTION • Plasticis the generic name for a family of synthetic materials derived from petrochemicals. • It is often product of two or more components. • There are many families of plastics and polymers being used in construction industry.

- 2. • Examples of plastics used in building are: Acrylic Composites Expanded Polystyrene Polycarbonate Polyethylene Polypropylene Polyvinyl Chloride

- 3. PROPERTIES • Plastics are strong yet lightweight, and so they are easy to transport & manoeuvre. • They are durable, knock-and scratch resistant with excellent weatherability. • They do not rot or corrode. • Plastics are easy to install; many have a snap-fit kind of jointing procedures. • Plastics offer limitless possibilities in design achieved by extrusion, bending, moulding etc.

- 4. • They can be given any range of colours by adding pigments. • The plastics are low conductors of heat and thus are used as insulation materials in green building concepts. • The plastics products can achieve tight seals. • They can be sawn and nailed employing standard carpentry tools and skills. • They can be easily removed and recycled. • They are bad conductors of electricity.

- 5. POLYMERS IN CONSTRUCTION • Polymer materialsaccount for the highest growth area in construction materials. • Polymers are very long molecules typicallymade up of many thousands of repeat units. They include plastics, rubbers,thermoplastic elastomers, adhesives, foams, paintsand sealants. • Applicationsof polymers in construction include areas such as flooring, windows, cladding, rainwater,pipes, membranes, seals, glazing, insulation and signage. • Performance and propertiesof polymers are relativelynew compared to traditionalmaterial types that have been in use for years.

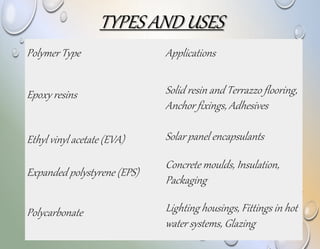

- 6. TYPES AND USES Polymer Type Applications Epoxy resins Solid resin and Terrazzo flooring, Anchor fixings, Adhesives Ethyl vinyl acetate (EVA) Solar panel encapsulants Expanded polystyrene (EPS) Concrete moulds, Insulation, Packaging Polycarbonate Lighting housings, Fittings in hot water systems, Glazing

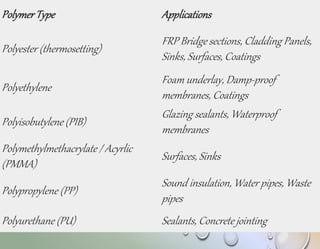

- 7. PolymerType Applications Polyester (thermosetting) FRP Bridge sections, Cladding Panels, Sinks, Surfaces, Coatings Polyethylene Foam underlay, Damp-proof membranes, Coatings Polyisobutylene (PIB) Glazing sealants, Waterproof membranes Polymethylmethacrylate / Acyrlic (PMMA) Surfaces, Sinks Polypropylene (PP) Sound insulation, Water pipes, Waste pipes Polyurethane (PU) Sealants, Concrete jointing

- 8. Polyvinylchloride (PVC) Sealants, Concrete jointing Rubber Bridge bearings, Flooring

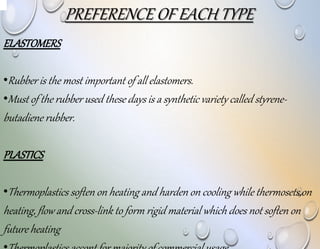

- 9. PREFERENCE OF EACH TYPE ELASTOMERS •Rubber is the most important of all elastomers. •Must of the rubber used these days is a synthetic variety called styrene- butadiene rubber. PLASTICS •Thermoplastics soften on heating and harden on cooling while thermosets,on heating, flow and cross-link to form rigid material which does not soften on future heating

- 10. FIBRES Fibres represent a very important application of polymeric materials. Synthetic polymers posess desirable characteristics such as high softening point to allow for ironing high tensile strength , adequate stiffness, and desirable constuction requirements.

- 11. ADVANTAGES • Low density • Corroision resistance • Easy to manufacture and can be moulded into complex shapes • Used for electrical insulation • Low thermal conductivity • Require low finishing cost • Tough and ductile

- 12. DISADVANTAGES • Low use temperature • Time temperature dependance • Low strength • Fatigue sensitivity • Swell with water if left for longer time • Toxicity and flammability • U.V. light sensitivity

- 13. CLASSIFICATION • Depending on how they are linked or joined (chemical bonds or intermolecular forces) and on the arrangement of the different chains that forms the polymer, the resulting polymeric materials can be classified as: • Thermoplastics • Elastomers • Thermosets

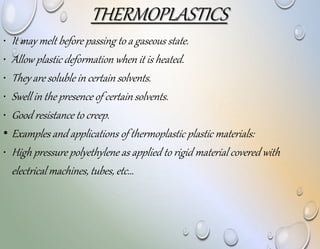

- 14. THERMOPLASTICS • It may melt before passing to a gaseous state. • Allow plastic deformation when it is heated. • They are soluble in certain solvents. • Swell in the presence of certain solvents. • Good resistance to creep. • Examples and applications of thermoplastic plastic materials: • High pressure polyethylene as applied to rigid material covered with electrical machines, tubes, etc...

- 15. • Low pressure polyethylene elastic material used for insulation of electrical cables, etc... • Polystyrene applied for electrical insulation, handles of tools... • Polyamide used for making ropes, belts, etc... • PVC or polyvinyl chloride for the manufacture of insulation materials, pipes, containers, etc...

- 16. ELASTOMERS • Depending on the distribution and degree of the chemical bonds of the polymers, elastomeric materials can be classified into: • Thermoset Elastomers - are those elastomer materials which do not melt when heated. • Thermoplastic Elastomers - are those elastomers which melt when heated. Properties of elastomer materials: Can not melt, before melting they pass into a gaseous state

- 17.  Swell in the presence of certain solvents  Are generally insoluble.  Are flexible and elastic.  Lower creep resistance than the thermoplastic materials

- 18. THERMOSETS • You can not melt. • Generally do not swell in the presence of certain solvents • They are insoluble. • High resistanceto creep • Examples and applicationsof thermoset plastic materials: • Epoxy resins - used as coating materials, caulks, manufactureof insulating materials,etc ... • Phenolic resins - tool handles, billiard balls,sprockets, insulation,etc ... • Unsaturatedpolyester resins - manufactureof plastics reinforced fiberglass commonly known as polyester, fillers, etc ...

- 19. LIMITATIONS • Plasticsmay be degraded under the action of direct sunlight which reduces their mechanical strength. • Many plastics are flammable unless treated. • High embodied energy content • Low modulus of elasticity:makes them unsuitablefor load-bearing applications. • Thermoplastics are subject to creep and soften at moderate temperatures. • Thermal expansion for most plastics is high: adequatethermal movement has to be allowed in detailing.

- 20. THANK YOU