Poster Presentation at MIT

Download as PPTX, PDF1 like563 views

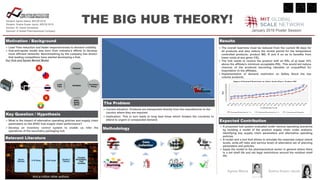

The document proposes implementing a hub-and-spoke distribution model for a global pharmaceutical company to reduce lead times and improve responsiveness. It analyzes how alternative operating policies and supply chain parameters would impact performance of an Asia Pacific distribution hub. A simulation tool would allow testing different planning parameters and policies, such as inventory levels, minimum order quantities, and safety stock. The hub aims to receive products with at least 10% remaining shelf life above affiliates' minimum to reduce obsolescence risks. Demand restriction for low volume productsâ safety stock is also proposed.

1 of 1

Download to read offline

Recommended

Supply chain innovation with iNewtrition

Supply chain innovation with iNewtritioninewtrition

Ėý

At the intersection of supply chain management, political economy, geography, and global governance, research on traders as key sustainability governance actors also provides novel opportunities for interdisciplinary work and stakeholder engagement to support innovation of products, services and technologies.FSP Services: Global Reach, Local Touch

FSP Services: Global Reach, Local TouchCovance

Ėý

Global Reach, Local Touch outlines factors for drug developers to consider when choosing a functional service provider (FSP) partner, including global reach, expertise that can scale up or down on demand, technology platform flexibility, and staff continuity. The document discusses two FSP models - the Clinical FSP model which provides resource flexibility and operational efficiency, and the Clinical Analytics model which consists of services such as clinical data management and biostatistics. It emphasizes that differentiation can be found in a provider's ability to seamlessly adapt to sophisticated clinical trial technology, retain talent that flexibly fits trial needs, and design effective staff onboarding transitions.Data analysis for scientific enterprises

Data analysis for scientific enterprisesinewtrition

Ėý

Data analysis can provide several advantages for scientific enterprises by enabling smart decision making, technical solutions, maximizing quality, minimizing costs and waste, and optimizing efficiency. The document then discusses how data analysis can improve technical operations related to product quality, purity, production efficiency, and cost/waste reduction. It also presents a case study on how data analysis of plant-based proteins can provide insights into ideal customers, maximizing sales, and identifying promotional targets.Drug Development Solutions Distinctly for the Progressive Biopharma Ventures ...

Drug Development Solutions Distinctly for the Progressive Biopharma Ventures ...Covance

Ėý

This document advertises drug development services from Covance that are designed around the client's needs and goals. It highlights personalized attention from dedicated teams, collaborative engagement through ongoing communication and technology, and access to specialized scientific and regulatory expertise to help clients navigate potential issues. Clients can choose from various solutions and services at any stage of drug development, from early research through clinical trials and regulatory approval, to fit their goals and vision.Covance Clinical-Biotech: Clinical Trials Designed Around YouÂŪ

Covance Clinical-Biotech: Clinical Trials Designed Around YouÂŪCovance

Ėý

Advance your clinical trial, your way - with a dedicated, flexible approach that's specifically designed for nimble and progressive biotech firms. From specialized expertise on your program team to tailored payment and communication schedules - you'll find unique options to personalize your trial so it works just for you.

Presentation bcp

Presentation bcpMenna Ahmed

Ėý

This document outlines a business continuity plan for a laboratory. It includes the laboratory's vision and mission, which is to provide high quality services. The plan's purpose is to maintain operations if a critical incident occurs. Objectives are to minimize impacts, ensure continuity, and identify roles. A SWOT analysis identifies strengths like experienced staff and weaknesses like financial limitations. Risks like fires and equipment failures are assessed. Priorities are patient safety and quick recovery. Roles define the director's leadership and staff responsibilities to be aware of and participate in the plan. The plan will be activated in an emergency, tested annually, and reviewed yearly.MTC Supply chain optimization

MTC Supply chain optimizationAdarsh Srivastava

Ėý

MTC is looking to optimize its supply chain to offset a new ACA tax through cost savings. It is considering short, mid, and long-term projects like developing a strategic partnership with a sterilization supplier, reducing sales force and branch offices, a mobile app for medical professionals, and moving to a distributor-only sales model. Financial analysis shows room for improving SG&A expenses relative to revenue growth. Proposed changes aim to reduce lead times, increase visibility, cut overhead costs, and lower inventory levels.Accelerate Your Scientific Discovery with GlobalCODEÂŪ - A Unique Data Managem...

Accelerate Your Scientific Discovery with GlobalCODEÂŪ - A Unique Data Managem...Covance

Ėý

GlobalCODE helps you unify your data and accelerate scientific discovery. Discover the benefits of unified specimen data. Application of Decision Sciences to Solve Business Problems in the Consumer P...

Application of Decision Sciences to Solve Business Problems in the Consumer P...Marketelligent

Ėý

Application of Decision Sciences to Solve Business Problems in the Consumer Packaged Goods (CPG) IndustryUK FCA Sandbox Overview

UK FCA Sandbox OverviewOxbow Partners

Ėý

The UK Financial Services Authority (FCA) has recently launched a "regulatory sandbox" to allow insurance startups to innovate in a safe regulatory environment. Charlie Burgess, a Founding Partner at Oxbow Partners, explores what this means for insurance startup businesses.Mb0044 production and operation management

Mb0044 production and operation managementsmumbahelp

Ėý

Dear students get fully solved assignments

Send your semester & Specialization name to our mail id :

â help.mbaassignments@gmail.com â

or

Call us at : 08263069601

(Prefer mailing. Call in emergency )Mb0044 production and operation management

Mb0044 production and operation managementsmumbahelp

Ėý

Dear students get fully solved SMU MBA assignments

Send your semester & Specialization name to our mail id :

â help.mbaassignments@gmail.com â

or

Call us at : 08263069601

Session 4

Session 4Kinshook Chaturvedi

Ėý

The document discusses production planning systems including aggregate planning and master production scheduling. It provides an overview of different planning horizons and techniques for aggregate and master production scheduling. An example is given demonstrating how to develop a master production schedule over an 8 week planning horizon for 3 products considering demand forecasts, safety stocks and production capacity.MTC challenge for Saving Revenue

MTC challenge for Saving Revenue Rashedul Islam

Ėý

This document outlines proposals to optimize the supply chain of Medical Technologies Corporation (MTC) in order to save costs and compensate for a new medical device tax. Key proposals include establishing in-house sterilization, reducing inventory levels through a just-in-time approach, implementing smart kiosks and RFID tracking at hospitals, rationalizing sales commissions, and forming long-term partnerships with hospitals. These changes could reduce costs in operations, logistics, and sales to achieve the required savings while improving customer service and positioning MTC for future growth through potential mergers or acquisitions.Mtc challange for save revenue

Mtc challange for save revenueRashedul Islam

Ėý

This document outlines proposals to optimize Medical Technologies Corporation's (MTC) supply chain operations in order to save costs and compensate for a new medical device tax. Key proposals include establishing in-house sterilization, reducing inventory levels through a just-in-time approach, implementing smart kiosks and RFID tracking at hospitals, rationalizing sales commissions, and forming long-term partnerships with hospitals. These changes aim to cut costs in manufacturing, logistics, and sales in order to achieve the required 2.3% cost savings while improving customer service and positioning MTC for future growth through potential mergers and acquisitions.Supply Chain Prescriptions Improve Margins for Global Pharmaceutical Company

Supply Chain Prescriptions Improve Margins for Global Pharmaceutical CompanyAntuit

Ėý

Antuitâs supply chain optimization models have helped the client achieve nearly US$2 million in cost savings, further enhancing the profitability of the companyâs best selling product.eBook_InventoryOptimization

eBook_InventoryOptimizationWill Lovatt

Ėý

The document discusses using inventory modeling to develop a holistic inventory strategy. It describes how companies aim to improve service levels while reducing inventory levels, but it is difficult to do both simultaneously without modeling. The document outlines factors like demand variability, supply chain complexity, different types of inventory levels, and demand patterns that must be considered in developing an effective inventory strategy. It provides an example of how modeling helped a manufacturer optimize inventory levels at dealers and distribution centers.Dhaval Shah on "Strategic Alignment Of Projects For Higher Profits And Increa...

Dhaval Shah on "Strategic Alignment Of Projects For Higher Profits And Increa...PMI Pearl City Chapter

Ėý

Dhaval Shah on "Strategic Alignment Of Projects For Higher Profits And Increased Market Share" at PM Conference India 2009Om0013 advanced production and operations management

Om0013 advanced production and operations managementsmumbahelp

Ėý

This document provides information about getting fully solved assignments. It gives a mail ID and phone number to contact for assignment help. It provides details like the semester, subject code, name, credits and marks for the Advanced Production and Operations Management subject. It also includes sample questions and answers related to the subject matter. The questions cover topics like types of operational strategies, computer-aided manufacturing, applications of just-in-time, new product development, V4L principles and demand management.Mb0044 production and operation management

Mb0044 production and operation managementsmumbahelp

Ėý

SABMiller, a $24 billion brewing company, revamped its supply chain management system to address stock-outs of popular brands. The company implemented a new forecasting and planning system using Infor software to better integrate demand data from various sources and optimize production scheduling and profits. The new system is being tested in South Africa with plans to roll it out globally. It aims to reduce stock-outs, improve forecasting accuracy by 40%, and lower costs.Saama Technologies Award Write Up

Saama Technologies Award Write UpClaudia Toscano

Ėý

Saama Technologies provides a clinical data integration and analytics platform that leverages machine learning to help life sciences companies optimize clinical trials and other processes. The platform can handle large amounts of structured and unstructured data. It has applications across the pharmaceutical value chain including supporting clinical trials through patient recruitment, site selection, and feasibility assessment using real-world data. Saama's focus on the life sciences industry helps clients apply real-world evidence to functions like drug discovery and regulatory support.Achieving Customer Specifications Through Process Improv.docx

Achieving Customer Specifications Through Process Improv.docxbartholomeocoombs

Ėý

Achieving Customer

Specifications Through

Process Improvement

Using Six Sigma: Case Study

of NutriSoil â Portugal

AMÃNDIO PEREIRA BAÃA, POLYTECHNIC OF GUARDA â PORTUGAL AND UDI â

RESEARCH UNIT FOR INLAND DEVELOPMENT OF GUARDA

ÂĐ 2015, ASQ

Tolerance limits are essential in production process

management, as they determine consumer satis-

faction. The use of statistical quality control tools

allows for process improvement and the cpk index

enables its measurement. Above all, the adoption

by businesses of lean tools has been crucial in

reducing the variation of a process or a product,

satisfying the consumerâs specifications, eliminat-

ing defects, reducing operating costs, and, in short,

increasing profitability.

The NutriSoil Company in Portugal, a small and

medium-sized enterprise (SME), sells fertilizer in

bags. The company has had problems with its filling

process due to excess weight of the bags. Results show

that by implementing Six Sigma combined with the 5S

program, NutriSoil achieved an improvement in its

cpk index for this process, which increased consumer

satisfaction and a highly significant cost savings. This

resulted in increased competitiveness.

Key words: cp and cpk capability index, process

capability, process improvement, Six Sigma, SME,

statistical quality control

INTRODUCTION

The basic objective of this study is to explore, using

a case study, the benefits of implementing the strat-

egy of Six Sigma combined with the 5S program in

NutriSoil, a Portuguese small and medium-sized enter-

prise (SME) struggling to retain profitability. NutriSoil

had high production costs, a situation that is common

to many SMEs.

The specifications or tolerance limits define the dif-

ference between acceptable and unacceptable products,

and producing within these limits is critical to con-

sumer satisfaction. The ability to consistently distribute

products within specifications determines whether the

supplier will continue to do business with the con-

sumer. A company can improve a production process

by efficiently coordinating the specifications and the

design process. Process capability measures how the

process meets specifications.

True process capability cannot be determined

until x-bar and R control charts have reached opti-

mum quality improvement without significant

investment in new equipment. A key aspect of process

improvement is to recognize that regardless of the

depth of this monitoring, there is always variation.

This variation is well defined when a process is sta-

tistically controlled. A modern definition of quality

48 QMJ VOL. 22, NO. 2/ÂĐ 2015, ASQ

Achieving Customer Specifications Through Process Improvement Using Six Sigma: Case Study of NutriSoil â Portugal

www.asq.org 49

dispersion permitted, that is, with specification limits. It

does, however, have a flaw; it assumes that the process

average is centered in the range of specifications. In

fact, it is not always so. .Capacity management

Capacity managementyashodeep more

Ėý

Capacity planning is determining the production capacity needed by a company to meet changing demands. It involves calculating the maximum output that can be produced with available resources, measuring capacity in units, and linking it to workforce planning. Capacity must account for seasonal or unexpected demand changes. There are three types of capacity considered: potential, immediate, and effective. Proper capacity planning ensures a company can meet customer requirements over time.Brand protection traceability through serialization

Brand protection traceability through serializationShari Popovich

Ėý

Counterfeit drugs is a global issue. Not isolated to certain countries or geographies.

The global economy demands a comprehensive and more robust supply chain to protect brands and their associated assets.

Brand owners and manufacturers face many challenges including the potential opportunity for counterfeit products to land in their supply chain.

Global regulatory bodies, governments, and pharmaceutical companies believe serialization is a required step to combat growing concern.

Serialization allows the unique identification of products and the ability to track these products through the supply chain.

A comprehensive system is required to identify and track products from manufacturer to consumer.

supply_chain_management.pdf

supply_chain_management.pdfCedrickBryllCastuloS

Ėý

This document provides an overview of supply chain management (SCM), including a definition, the importance of SCM, how it is applied today and expected to evolve in the future. It discusses key SCM principles and benefits, such as integrated management across organizations to improve customer satisfaction, increase sales and reduce costs. The document also gives examples of how SCM techniques have been implemented in various industries to reduce order-to-delivery times and improve profitability.Designing channels of distribution case

Designing channels of distribution caseDeepshikha Verma

Ėý

This document outlines a 6-step framework for designing distribution channels for new industrial products. The key steps are: 1) Identifying customer segments, 2) Prioritizing customers' channel function requirements, 3) Benchmarking the seller's and competitors' channel capabilities, 4) Generating feasible channel options, 5) Evaluating the costs and benefits of each option, and 6) Aggregating options to maximize synergies across product lines and markets. The goal is to systematically evaluate different channel structures and identify the option that best satisfies customers' needs while optimizing costs and revenues for the firm.Supply Chain Analytics with Simulation

Supply Chain Analytics with SimulationProModel Corporation

Ėý

Understand the value of simulation based predictive analytics for distribution center, supply chain, logistics, or warehouse design, operations and performance improvement More Related Content

Similar to Poster Presentation at MIT (20)

Application of Decision Sciences to Solve Business Problems in the Consumer P...

Application of Decision Sciences to Solve Business Problems in the Consumer P...Marketelligent

Ėý

Application of Decision Sciences to Solve Business Problems in the Consumer Packaged Goods (CPG) IndustryUK FCA Sandbox Overview

UK FCA Sandbox OverviewOxbow Partners

Ėý

The UK Financial Services Authority (FCA) has recently launched a "regulatory sandbox" to allow insurance startups to innovate in a safe regulatory environment. Charlie Burgess, a Founding Partner at Oxbow Partners, explores what this means for insurance startup businesses.Mb0044 production and operation management

Mb0044 production and operation managementsmumbahelp

Ėý

Dear students get fully solved assignments

Send your semester & Specialization name to our mail id :

â help.mbaassignments@gmail.com â

or

Call us at : 08263069601

(Prefer mailing. Call in emergency )Mb0044 production and operation management

Mb0044 production and operation managementsmumbahelp

Ėý

Dear students get fully solved SMU MBA assignments

Send your semester & Specialization name to our mail id :

â help.mbaassignments@gmail.com â

or

Call us at : 08263069601

Session 4

Session 4Kinshook Chaturvedi

Ėý

The document discusses production planning systems including aggregate planning and master production scheduling. It provides an overview of different planning horizons and techniques for aggregate and master production scheduling. An example is given demonstrating how to develop a master production schedule over an 8 week planning horizon for 3 products considering demand forecasts, safety stocks and production capacity.MTC challenge for Saving Revenue

MTC challenge for Saving Revenue Rashedul Islam

Ėý

This document outlines proposals to optimize the supply chain of Medical Technologies Corporation (MTC) in order to save costs and compensate for a new medical device tax. Key proposals include establishing in-house sterilization, reducing inventory levels through a just-in-time approach, implementing smart kiosks and RFID tracking at hospitals, rationalizing sales commissions, and forming long-term partnerships with hospitals. These changes could reduce costs in operations, logistics, and sales to achieve the required savings while improving customer service and positioning MTC for future growth through potential mergers or acquisitions.Mtc challange for save revenue

Mtc challange for save revenueRashedul Islam

Ėý

This document outlines proposals to optimize Medical Technologies Corporation's (MTC) supply chain operations in order to save costs and compensate for a new medical device tax. Key proposals include establishing in-house sterilization, reducing inventory levels through a just-in-time approach, implementing smart kiosks and RFID tracking at hospitals, rationalizing sales commissions, and forming long-term partnerships with hospitals. These changes aim to cut costs in manufacturing, logistics, and sales in order to achieve the required 2.3% cost savings while improving customer service and positioning MTC for future growth through potential mergers and acquisitions.Supply Chain Prescriptions Improve Margins for Global Pharmaceutical Company

Supply Chain Prescriptions Improve Margins for Global Pharmaceutical CompanyAntuit

Ėý

Antuitâs supply chain optimization models have helped the client achieve nearly US$2 million in cost savings, further enhancing the profitability of the companyâs best selling product.eBook_InventoryOptimization

eBook_InventoryOptimizationWill Lovatt

Ėý

The document discusses using inventory modeling to develop a holistic inventory strategy. It describes how companies aim to improve service levels while reducing inventory levels, but it is difficult to do both simultaneously without modeling. The document outlines factors like demand variability, supply chain complexity, different types of inventory levels, and demand patterns that must be considered in developing an effective inventory strategy. It provides an example of how modeling helped a manufacturer optimize inventory levels at dealers and distribution centers.Dhaval Shah on "Strategic Alignment Of Projects For Higher Profits And Increa...

Dhaval Shah on "Strategic Alignment Of Projects For Higher Profits And Increa...PMI Pearl City Chapter

Ėý

Dhaval Shah on "Strategic Alignment Of Projects For Higher Profits And Increased Market Share" at PM Conference India 2009Om0013 advanced production and operations management

Om0013 advanced production and operations managementsmumbahelp

Ėý

This document provides information about getting fully solved assignments. It gives a mail ID and phone number to contact for assignment help. It provides details like the semester, subject code, name, credits and marks for the Advanced Production and Operations Management subject. It also includes sample questions and answers related to the subject matter. The questions cover topics like types of operational strategies, computer-aided manufacturing, applications of just-in-time, new product development, V4L principles and demand management.Mb0044 production and operation management

Mb0044 production and operation managementsmumbahelp

Ėý

SABMiller, a $24 billion brewing company, revamped its supply chain management system to address stock-outs of popular brands. The company implemented a new forecasting and planning system using Infor software to better integrate demand data from various sources and optimize production scheduling and profits. The new system is being tested in South Africa with plans to roll it out globally. It aims to reduce stock-outs, improve forecasting accuracy by 40%, and lower costs.Saama Technologies Award Write Up

Saama Technologies Award Write UpClaudia Toscano

Ėý

Saama Technologies provides a clinical data integration and analytics platform that leverages machine learning to help life sciences companies optimize clinical trials and other processes. The platform can handle large amounts of structured and unstructured data. It has applications across the pharmaceutical value chain including supporting clinical trials through patient recruitment, site selection, and feasibility assessment using real-world data. Saama's focus on the life sciences industry helps clients apply real-world evidence to functions like drug discovery and regulatory support.Achieving Customer Specifications Through Process Improv.docx

Achieving Customer Specifications Through Process Improv.docxbartholomeocoombs

Ėý

Achieving Customer

Specifications Through

Process Improvement

Using Six Sigma: Case Study

of NutriSoil â Portugal

AMÃNDIO PEREIRA BAÃA, POLYTECHNIC OF GUARDA â PORTUGAL AND UDI â

RESEARCH UNIT FOR INLAND DEVELOPMENT OF GUARDA

ÂĐ 2015, ASQ

Tolerance limits are essential in production process

management, as they determine consumer satis-

faction. The use of statistical quality control tools

allows for process improvement and the cpk index

enables its measurement. Above all, the adoption

by businesses of lean tools has been crucial in

reducing the variation of a process or a product,

satisfying the consumerâs specifications, eliminat-

ing defects, reducing operating costs, and, in short,

increasing profitability.

The NutriSoil Company in Portugal, a small and

medium-sized enterprise (SME), sells fertilizer in

bags. The company has had problems with its filling

process due to excess weight of the bags. Results show

that by implementing Six Sigma combined with the 5S

program, NutriSoil achieved an improvement in its

cpk index for this process, which increased consumer

satisfaction and a highly significant cost savings. This

resulted in increased competitiveness.

Key words: cp and cpk capability index, process

capability, process improvement, Six Sigma, SME,

statistical quality control

INTRODUCTION

The basic objective of this study is to explore, using

a case study, the benefits of implementing the strat-

egy of Six Sigma combined with the 5S program in

NutriSoil, a Portuguese small and medium-sized enter-

prise (SME) struggling to retain profitability. NutriSoil

had high production costs, a situation that is common

to many SMEs.

The specifications or tolerance limits define the dif-

ference between acceptable and unacceptable products,

and producing within these limits is critical to con-

sumer satisfaction. The ability to consistently distribute

products within specifications determines whether the

supplier will continue to do business with the con-

sumer. A company can improve a production process

by efficiently coordinating the specifications and the

design process. Process capability measures how the

process meets specifications.

True process capability cannot be determined

until x-bar and R control charts have reached opti-

mum quality improvement without significant

investment in new equipment. A key aspect of process

improvement is to recognize that regardless of the

depth of this monitoring, there is always variation.

This variation is well defined when a process is sta-

tistically controlled. A modern definition of quality

48 QMJ VOL. 22, NO. 2/ÂĐ 2015, ASQ

Achieving Customer Specifications Through Process Improvement Using Six Sigma: Case Study of NutriSoil â Portugal

www.asq.org 49

dispersion permitted, that is, with specification limits. It

does, however, have a flaw; it assumes that the process

average is centered in the range of specifications. In

fact, it is not always so. .Capacity management

Capacity managementyashodeep more

Ėý

Capacity planning is determining the production capacity needed by a company to meet changing demands. It involves calculating the maximum output that can be produced with available resources, measuring capacity in units, and linking it to workforce planning. Capacity must account for seasonal or unexpected demand changes. There are three types of capacity considered: potential, immediate, and effective. Proper capacity planning ensures a company can meet customer requirements over time.Brand protection traceability through serialization

Brand protection traceability through serializationShari Popovich

Ėý

Counterfeit drugs is a global issue. Not isolated to certain countries or geographies.

The global economy demands a comprehensive and more robust supply chain to protect brands and their associated assets.

Brand owners and manufacturers face many challenges including the potential opportunity for counterfeit products to land in their supply chain.

Global regulatory bodies, governments, and pharmaceutical companies believe serialization is a required step to combat growing concern.

Serialization allows the unique identification of products and the ability to track these products through the supply chain.

A comprehensive system is required to identify and track products from manufacturer to consumer.

supply_chain_management.pdf

supply_chain_management.pdfCedrickBryllCastuloS

Ėý

This document provides an overview of supply chain management (SCM), including a definition, the importance of SCM, how it is applied today and expected to evolve in the future. It discusses key SCM principles and benefits, such as integrated management across organizations to improve customer satisfaction, increase sales and reduce costs. The document also gives examples of how SCM techniques have been implemented in various industries to reduce order-to-delivery times and improve profitability.Designing channels of distribution case

Designing channels of distribution caseDeepshikha Verma

Ėý

This document outlines a 6-step framework for designing distribution channels for new industrial products. The key steps are: 1) Identifying customer segments, 2) Prioritizing customers' channel function requirements, 3) Benchmarking the seller's and competitors' channel capabilities, 4) Generating feasible channel options, 5) Evaluating the costs and benefits of each option, and 6) Aggregating options to maximize synergies across product lines and markets. The goal is to systematically evaluate different channel structures and identify the option that best satisfies customers' needs while optimizing costs and revenues for the firm.Supply Chain Analytics with Simulation

Supply Chain Analytics with SimulationProModel Corporation

Ėý

Understand the value of simulation based predictive analytics for distribution center, supply chain, logistics, or warehouse design, operations and performance improvement Dhaval Shah on "Strategic Alignment Of Projects For Higher Profits And Increa...

Dhaval Shah on "Strategic Alignment Of Projects For Higher Profits And Increa...PMI Pearl City Chapter

Ėý

Poster Presentation at MIT

- 1. Sneha Susan JacobAgnes Maina THE BIG HUB THEORY!Student: Agnes Maina, MSCM 2016 Student: Sneha Susan Jacob, MSCM 2016 Advisor: Dr. David Gonsalvez Sponsor: A Global Pharmaceutical Company ï Lead Time reduction and faster responsiveness to demand volatility ï Hub-and-spoke model was born from industryâs efforts to develop more efficient networks. Benchmarking by the company has shown that leading competitors have started developing a Hub. Our Hub and Spoke Mental Model ï What is the impact of alternative operating policies and supply chain parameters on the APAC hub supply chain performance? ï Develop an inventory control system to enable us infer the operations of the secondary packaging hub ï A proposed hub system evaluated under various operating scenarios by building a model of the product supply chain under analysis, identifying key supply chain parameters and alternative operating policies. ï A model and a tool that allows to simulate the expected output (stock levels, write-off risks and service level) of alternative set of planning parameters and policies. ï Apply the model to the pharmaceutical sector in general where there is a set shelf life and set legal restrictions around the residual shelf life. ï The overall lead-time must be reduced from the current 90 days for all products and also reduce the review period for the temperature controlled products; product MD, R and X so as to benefits from lower costs at any given CSL. ï The hub needs to receive the product with an RSL of at least 10% above the affiliateâs minimum acceptable RSL. This would aid reduce chances of the products becoming obsolete or unqualified for importation to the affiliates. ï Implementation of demand restriction on Safety Stock the low volume products. Methodology The Problem Motivation / Background Key Question / Hypothesis Relevant Literature Results Expected Contribution ï Current situation: Products are transported directly from the manufacturer to the country where they are required. ï Implication: This in turn leads to long lead times which hinders the countries to attend to urgent or unexpected demand. January 2016 Poster Session And a million other authors Variables Demand Inventory Policy MOQ, Safety Stock Lead Time 8 10 12 14 16 18 20 22 24 26 28 30 89.5% 90.0% 90.5% 91.0% 91.5% 92.0% 92.5% 93.0% 93.5% 94.0% 94.5% 95.0% 95.5% 96.0% 96.5% 97.0% 97.5% 98.0% 98.5% 99.0% 99.5% 99.9% Days Cycle Service Level Impact of Demand Restriction on Safety Stock (Days): Product MD Demand Restricted at 1 Ï Demand Restricted at 2 Ï Unrestricted Demand