Post-tensioning in Prestressed Concrete

- 2. POST-TENSIONING ’üĄ THE TENSION IS APPLIED TO THE TENDONS AFTER HARDENING OF THE CONCRETE. ’üĄ MINIMUM GRADE OF CONCRETE USED IS 30 MPa. ’üĄ DUCTS ARE PROVIDED IN THIS TYPE OF PRESTRESSING.

- 3. POST-TENSIONING ’üĄ IN POST-TENSIONING SYSTEMS, THE TENDONS ARE PLACED IN DUCTS AFTER THE CASTING OF CONCRETE. ’üĄ THE DUCT PREVENTS BOND BETWEEN CONCRETE AND THE TENDONS DURING THE TENSIONING OPERATION. ’üĄ UNLIKE PRE-TENSIONING, THE TENDONS ARE PULLED WITH THE REACTION ACTING AGAINST THE HARDENED CONCRETE.

- 4. POST-TENSIONING TYPES ’üĄ IF THE DUCTS PROVIDED ARE GROUTED THEN IT IS CALLED BONDED POST-TENSIONING. ’üĄ AND IF DUCTS ARE NOT GROUTED THEN IT IS CALLED UNBONDED POST-TENSIONING. TENDON IS HELD IN POSITION BY END ANCHORAGES.

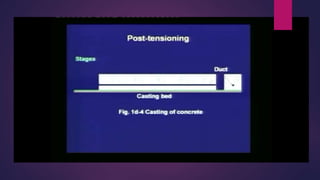

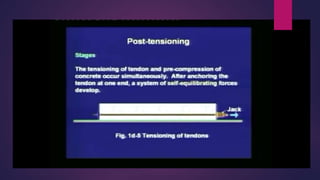

- 7. POST-TENSIONING STAGES ’üĄ The various stages of the post-tensioning operation are summarised as follows. ’üĄ 1) Casting of concrete. ’üĄ 2) Placement of the tendons. ’üĄ 3) Placement of the anchorage block and jack. ’üĄ 4) Applying tension to the tendons. ’üĄ 5) Seating of the wedges. ’üĄ 6) Cutting of the tendons.

- 13. POST-TENSIONING ADVANTAGES ’üĄ The relative advantages of post-tensioning as compared to pre-tensioning are as follows. ’üĄ Post-tensioning is suitable for heavy cast-in- place members. ’üĄ The waiting period in the casting bed is less. ’üĄ The transfer of prestress is independent of transmission length.

- 14. POST-TENSIONING DISADVANTAGES ’üĄ The relative disadvantage of post-tensioning as compared to pre-tensioning is the requirement of anchorage device and grouting equipment.

- 15. DEVICES ’üĄ The essential devices for post-tensioning are as follows. ’üĄ 1) Casting bed ’üĄ 2) Mould/Shuttering ’üĄ 3) Ducts ’üĄ 4) Anchoring devices ’üĄ 5) Jacks ’üĄ 6) Couplers (optional) ’üĄ 7) Grouting equipment (optional)

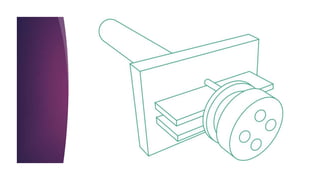

- 16. ANCHORAGE DEVICES ’üĄ In post-tensioned members the anchoring devices transfer the prestress to the concrete. The devices are based on the following principles of anchoring the tendons. ’üĄ 1) Wedge action ’üĄ 2) Direct bearing ’üĄ 3) Looping the wires

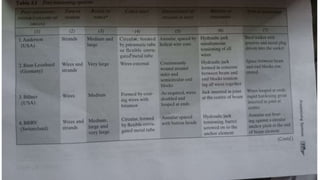

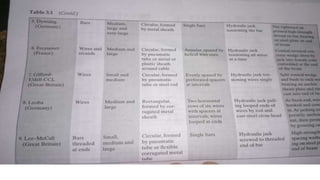

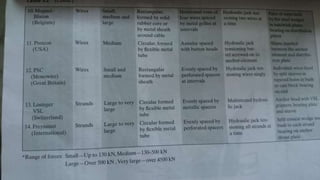

- 17. WEDGE ACTION ’üĄ The anchoring device based on wedge action consists of an anchorage block and wedges. The strands are held by frictional grip of the wedges in the anchorage block. Some examples of systems based on the wedge-action are Freyssinet, Gifford-Udall, Anderson and Magnel- Blaton anchorages

- 18. 18

- 20. DIRECT BEARING ’üĄ The rivet or bolt heads or button heads formed at the end of the wires directly bear against a block. The B.B.R.V post-tensioning system and the Prescon system are based on this principle.

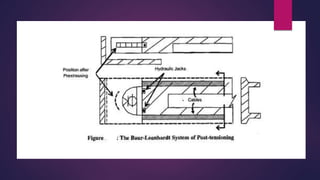

- 23. LOOPING THE WIRES ’üĄ The Baur-Leonhardt system, Leoba system and also the Dwidag single-bar anchorage system, work on this principle where the wires are looped around the concrete. The wires are looped to make a bulb.

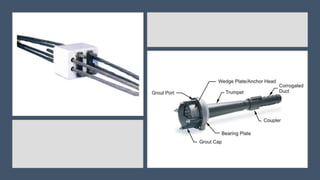

- 25. COUPLERS ’üĄ The couplers are used to connect strands or bars. They are located at the junction of the members, for example at or near columns in post-tensioned slabs, on piers in posttensioned bridge decks. The couplers are tested to transmit the full capacity of the strands or bars.

- 27. ’üĄ MORE THAN 64 SYSTEMS HAVE BEEN PATENTED ACROSS THE WORLD. ’üĄ FREYSSINET SYSTEM IS COMMONLY USED IN INDIA.

- 31. 31