Poultry World Article September 2014

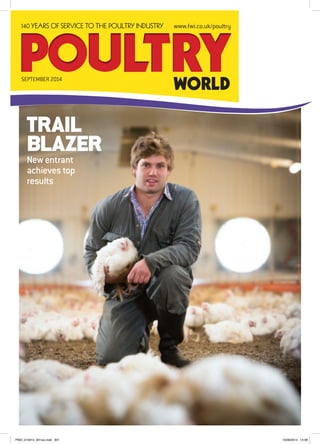

- 1. SEPTEMBER 2014 www.fwi.co.uk/poultry WORLD 140 YEARS OF SERVICE TO THE POULTRY INDUSTRY TRAIL BLAZERNew entrant achieves top results PWO_010914_301rev.indd 301 15/09/2014 14:38

- 2. REPRINTED FROM SEPTEMBER 2014 Ō£▒ POULTRYWORLDPOULTRYWORLD Ō£▒ SEPTEMBER 2014 19THE NEW ENTRANT18 THE NEW ENTRANT People who have got about 300-400 acres at home, who are coming back from university and want to make their mark, have been getting in touch HARRYSHEPHERD ŌĆ£ On the road to the next shed ŌØÜ Builders are booked for a second shed, and construction is due to start in April. The challenges and successes of the last few crops are feeding into design tweaks. The headline change is that it will be a fair bit bigger. ŌĆ£WeŌĆÖre going to go longer for the next shed, to about 400ft, as the site will need an IPPC licence anyway.ŌĆØ That will take about 48,000 birds, adding to the 38,000 capacity of the existing building. ŌĆ£IŌĆÖm going to install bigger roof fans, as well. Instead of 710mm fans, I will go for between 800mm and 900mm, as IŌĆÖve found minimum ventilation easier to manage using the roof rather than the gable end fans. I want the best ventilation possible for those crucial first days of a birdŌĆÖs life.ŌĆØ Gable end fans have thrown up another headache. The Flockman system needs an even distribution of feed, and birds have been scared to use those pans at the end of the line when the fans are spinning. This means feed could be empty apart from at the final feeders, which con- fuses the sensors. ŌĆ£IŌĆÖve moved the proximity sensors a bit further back,ŌĆØ says Harry. ŌĆ£People on ad lib would say it didnŌĆÖt matter, but itŌĆÖs essential with this system that the whole house is getting even amounts of feed.ŌĆØ HarryŌĆÖs bank has been pleased enough with the performance this year to approve financing for the second shed, coupled with the purchase of a biomass boiler. It means adding almost half a million pounds to the mortgage, but itŌĆÖs a mark of confidence in the 26-year-old. After much consideration he is ŌĆ£almost settledŌĆØ on a 500kW unit sup- plied by EDM Energy, the firm run by friend and mentor Ed Barker. ItŌĆÖs one of the only boilers registered for RHI to burn shredded pallet waste ŌĆō a key consideration. ŌĆ£Woodchip and wood pellet are going through the roof; I can get shredded pallet waste for ┬Ż40-50/t.ŌĆØ The reasoning behind a 500kW boiler, when two at less than half that capacity would generate more subsidy, is that capital expenditure is cut almost in half. ŌĆ£I canŌĆÖt wait to get the next shed up ŌĆō the next chapter in my 10-year plan. Instead of relying solely on the first, you can spread the risk if, say, one gets a hit. It will be a lot of pressure off my mind.ŌĆØ EXPANSIONPLANS I t was clear from the outset that one standard broiler unit would not be enough to occupy all of Harry ShepherdŌĆÖs attention for long. Even when Poultry World first vis- ited his skeleton of a shed back in September 2013, plans for expan- sion, developing the business and getting the best performance from his birds were all well formed in his mind. Given 12 months in a commer- cial setting, Harry has had a chance to prove he is able to meet with those measures that define early success. Financially, the business has progressed as expected, the bank manager is happy enough to extend the mortgage and builders have now been booked for the con- struction of a second shed. HarryŌĆÖs husbandry of the birds has improved with each crop, and this summer he achieved an EPEF (European Production Efficiency Factor) of just over 400. This is de- spite health challenges and teething problems with the new shed, its equipment and operating it with a relative lack of experience. ŌĆ£The first year has thrown up so many opportunities,ŌĆØ says Harry, pointing to the different directions that now face him following his short time within the poultry in- dustry. He has had consultancy offers, is providing telephone support for a highly technical management sys- tem, and is still able to have part- time work that allows him to keep personal expenditure and the poul- try business profits separate. HEATCONTROL The big challenge in recent weeks and months has been keeping the shed temperate, despite an unusu- ally hot stretch of weather. ŌĆ£Manag- ing the ventilation in summer has been a completely different ball- Farm facts ŌØÜ Forest Poultry ŌØÜ One shed on a 5ha site ŌØÜ 38,000 pre-sexed broilers ŌØÜ Contracted to Sullivan Poultry ŌØÜ Best EPEF of 401 Healthproblems sorted,flockEPEF soarstoover400 NewentrantHarryShepherdtells JakeDavies of thechallenges and achievements thathavearisen inhis first12monthsasabroilerfarmer lowered the price paid for poultry. ŌĆ£Hopefully itŌĆÖs a temporary thing, and will come back round,ŌĆØ he says. Therein lies the risks from the in- dependent sector; the price of birds can change mid-crop, and the cut that is hurting right now happened with birds already in sheds. It was caused by a sudden glut of poultry dumped on the wholesale market, he explains. Despite the challenges presented with a price in flux, he is happy for the moment with processor Sul- livanŌĆÖs, part of ABN. Would he consider a switch to an integrator? ŌĆ£On the whole I think it works out to be more profitable to be with an independent. The only detractor with wholesale is plan- ning, as supermarket suppliers will set catching times when the crop comes in. Planning would be much easier.ŌĆØ Feed cost coming down has been the saving grace. But it has high- lighted for Harry the importance of buying at the right time. ŌĆ£If IŌĆÖd thought ┬Ż160/t for wheat was cheap six months ago, and had fixed be- fore the price had come down, it would have hurt the business. ŌĆ£I need to get a little bit more clued up on fixing feed,ŌĆØ he admits, Equally, he says, he doesnŌĆÖt want his business to be run on the lines of a man at the roulette table. THEFUTURE So thereŌĆÖs a lot in the pipeline following the first 12 months of our new entrant. In addition, he has been taking phone calls from friends who are also considering a move into broiler growing. ŌĆ£People who have got about 300-400 acres at home, who are coming back from university and want to make their mark, have been getting in touch.ŌĆØ One has asked Harry to consult on the construction of his first shed. His focus will remain on the home farm, though, and the plan to have six sheds within the first 10 years is a target that has every sign of being met. JIMVARNEY Achangetofeedingpracticehashelpedboostflockperformance. game to winter,ŌĆØ says Harry. ŌĆ£These last two crops have been the most difficult.ŌĆØ For the first seven days, the heat is not such a problem, he explains. But when birds get larger and begin putting on weight, keeping the tem- perature under control became in- creasingly difficult. ŌĆ£There was one Saturday where I didnŌĆÖt know where to turn, really. Temperature was 3C above set and rising. I didnŌĆÖt dare bring any more air into the shed for fear of chilling birds without the feather coverage.ŌĆØ In the end, the temperature was brought back under control, but a more long-term fix meant a fun- damental change in the ventilation computerŌĆÖs set-up. Instead of work- ing on time, it now adjusts based on temperature ŌĆō just one of many tweaks that has been made over the last year to make management easier. FEEDINGSYSTEMS One big change that Harry feels helped give a boost to that all-im- portant EPEF score was the intro- duction of the FLOCKMAN feed control system. ŌĆ£It basically keeps an edge on CLEANING Another management tweak has been a change of washing team. Harry now takes one washer himself and joins a team of three others, tak- ing personal responsibility for about a third of his building. ŌĆ£I quite like doing it,ŌĆØ he says. The last time Poultry World vis- ited, the shed had experienced a number of health problems. For Harry itŌĆÖs the hardest part of the job. ŌĆ£ItŌĆÖs hugely demoralising, when you go in to that shed and water consumption is down, litter is wet and the birds are looking unhappy. ŌĆ£Generally, though, health is much better. WeŌĆÖre still getting nig- gles, and I donŌĆÖt know where they come from. IŌĆÖm just really focused on getting the right balance of air and pressure, as well as continuing to rotate litter to keep it from cap- ping.ŌĆØ MARKETING The vagaries of operating in a free market, and in the independent side of the poultry sector ŌĆō where farmers finance their own feed and chicks ŌĆō has been a learning curve for Harry. A challenge has recent- ly reared its head as his integrator the appetite,ŌĆØ he explains. Alternate periods of light and dark are inter- spersed with feeding sessions, and pans are allowed to empty. It trains birds to eat when food appears, and means that appetites are kept up when closer to slaughter weight. Initial results seem promis- ing, says Harry. ŌĆ£Because you restrict feed, growth is slowed in the early stages, allowing for better devel- opment. This cuts down on the potential for ascites later in the crop. There have probably been 60% fewer heart attacks since weŌĆÖve begun using it.ŌĆØ There has also been a big reduc- tion in feed consumption overall, combined with lower mortality and better feed conversion. This has all helped him attain an EPEF of 401. He joins just a handful of UK farm- ers that have managed to get above that golden standard. ŌĆ£The first crop with Flockman was a bit of a nightmare,ŌĆØ admits Harry. It added a lot of time and effort to management. But once the pan settings had been tweaked, things began moving a lot more smoothly. ŌĆ£I think itŌĆÖs paid for itself in a crop-and-a-half.ŌĆØ PWO_010914_018-019rev.indd All Pages 16/09/2014 09:16

- 3. FLOCKMANA revolutionary way to feed broilers. Birds are fed several feeds a day and not ad-lib. The birds tell FLOCKMAN how much feed they need. Results: lower Mortality, better growth, FCR, EPEF and profit. Needs stockmen to learn ŌĆ£Feed Pan ManagementŌĆØ techniques. Took David Filmer (ex BOCM Technical Director, Dalgety) 25 years to work out! Payback in 1-2 crops: e-mail harry-shepherd@hotmail.co.uk or Tel 07725 899716. 9 International trials 2.2 M birds Results 36-46 day old A/H flocks ITEM BENEFIT Average BENEFIT Minimum BENEFIT Maximum Mortality 1.01% 0.28% 1.74% Liveweight g 40 10 70 FCR 0.062 0.046 0.078 EPEF 17.6 11.0 24.2 Margin/bird p Margin/bird US cents 4.32 7.34 3.14 5.34 5.50 9.34 Margin/house ┬Ż Margin/house US $ ┬Ż1,463 $2,485 ┬Ż1,053 $1,789 ┬Ż1,873 $3,181 David Filmer MA (Cantab), Dip Ag (Cantab), BSc (Agric) (London), NDA. MD FLOCKMAN company. 48 Brent Street, Brent Knoll, Somerset, TA9 4DT, UK. e-mail address david@flockman.com Tel +44 1278 760 760: Mobile +44 7802 200 760: Fax +44 1278 760761 Skype Address david.filmer5 New Award winning website www.flockman.com Untitled-3 1 15/09/2014 15:02