Power Screw and its application

- 1. PPT Designed By Mohammedi Limdiwala

- 2. ’é×Power Screw ’é×Types of Power Screws ’é×Load Analysis ’é×Efficiency of power screw ’é×Threads ’é×Applications of Power Screw

- 3. ’é×A power screw is a drive used in machinery to convert a rotary motion into a linear motion for power transmission. ’é×It produces uniform motion and the design of the power screw may be such that: ’é×(a) Either yhe screw or the nut is held at rest and the other member rotates as it moves axially. Ex: screw clamp ’é×(b) Either the screw or the nut rotates but does not move axially. Ex: press

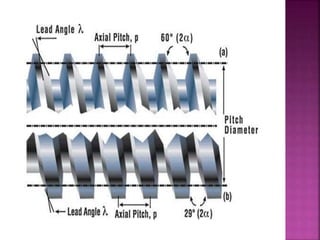

- 5. ’é×Strongest thread. ’é×No radial load. ’é×Hard to manufacture. ’é×Square threads have a much higher intrinsic efficiency than acme threads. ’é×Due to the lack of a thread angle there is no radial pressure, or bursting pressure, on the nut. This also increases the nut life. ’é×This thread is difficult in machining.

- 6. ’é×The square thread form is a common screw thread form, used in high load applications such as lead screws and jack screws. ’é× It gets its name from the square cross-section of the thread. ’é×It is the lowest friction and most efficient thread form, but it is difficult to fabricate.

- 8. ’é×The Acme thread form has a 29┬░ thread angle with a thread height half of the pitch. ’é×The apex and valley are flat. ’é× This shape is easier to machine than is a square thread. ’é× The tooth shape also has a wider base which means it is stronger than a similarly sized square thread. ’é× This thread form also allows for the use of a split nut, which can compensate for nut wear.

- 9. ’é×29┬░ included angle. ’é×Easier to manufacture. ’é×Common choice for loading in both directions. ’é×Faster cutting. ’é×Longer tool life.

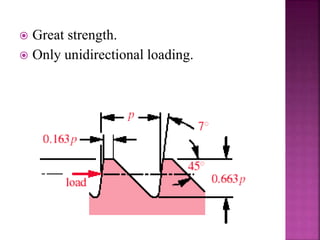

- 11. ’é×In machinery, the buttress thread form is designed to handle extremely high axial thrust in one direction. ’é× The load-bearing thread face is perpendicular to the screw axis or at a slight slant (usually not greater than 7┬░) ’é× The other face is slanted at 45┬░.

- 12. ’é× Great strength. ’é× Only unidirectional loading.

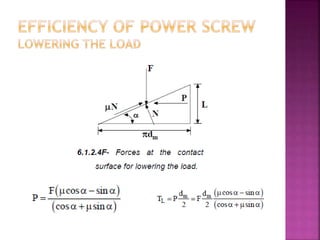

- 14. ’é× A square thread power screw with a single start is shown in figure. ’é× Here p is the pitch, ╬▒ the helix angle, dm the mean diameter of thread and F is the axial load. ’é× In order to analyze the mechanics of the power screw we need to consider two cases: ’éĪ Raising the load ’éĪ Lowering the load.

- 18. ’é× Here work output = F. L ’é× Work input = p. ŽĆdm

- 19. ’é× The load would lower itself without any external force if ŽĆ┬Ądm < L ’é× And some external force is required to lower the load if ŽĆ┬Ądm >= L ’é× Therefore this the condition of self locking.

- 20. ’é× The above analysis is for square thread and for trapezoidal thread some modification is required. Because of the thread angle the force normal to the thread surface is increased. ’é× The torque is therefore given by ’é× The increased friction is due to the wedging effect. But they are not preferred due to greater losses due to friction.

- 22. ’é× Bursting effect on the nut is caused by the horizontal component of the axial load F on the screw Fx = Ftan├ś ’é× For isometric nut 2├ś = 60┬║ and Fx = 0.5777F.

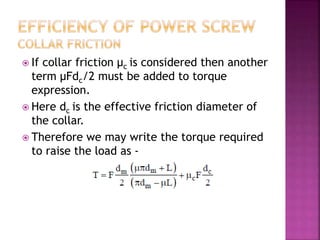

- 23. ’é× If collar friction ╬╝c is considered then another term ╬╝Fdc/2 must be added to torque expression. ’é× Here dc is the effective friction diameter of the collar. ’é× Therefore we may write the torque required to raise the load as -

- 24. ’ü░dp L ’ü¼ N f P F LIFTING y x pd L ’ü░ ’ü¼ ’ĆĮtan ’Ć© ’Ć® ’Ć© ’Ć®Ld LdPd T p pp Su ’üŁ’ü░ ’üŁ’ü░ ’ĆŁ ’Ć½ ’ĆĮ 2

- 25. p pitch in./thread d diameter (major) in. dp pitch diameter in. dr minor diameter in. L Lead in.

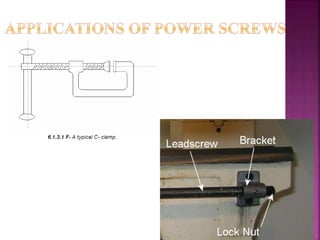

- 27. ’é×Jack screws ’é×Lead screws of a lathe ’é×Screw for vices ’é×Presses ’é×C-clamps ’é×Instron material testing machines ’é×Machine tools (for positioning of table)

- 31. ’é× Power screw drive in machinery is firstly discussed and some details of the thread forms used in such drives are given. The force system at the contact surface between the screw and the nut is analyzed and the torque required to raise and lower a load, condition for self locking and the efficiency of a power screw are derived.