PPEJ.090.2010 rev2

- 1. EPC ADDITIONAL OFFSHORE PIPELINE 10â â 22 KM PALANG TO FSO PPEJ-090/2010-S

- 2. TOPICS LIST 1. PROJECT INTRODUCTION 2. GLOBAL SCOPE OF WORK 3. FLOW CHART PIPELINE ENGINEERING 4. REFERENCE AND CODE STANDART 5. DETAIL SCOPE OF WORK 6. DATA REQUESTED

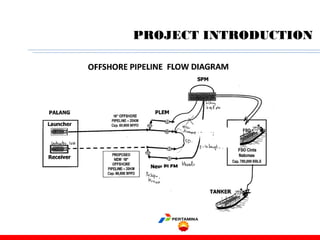

- 3. PROJECT INTRODUCTION PALANG AREA 22 KM EXISTING NEW PIPELINE FSO

- 5. âĒ Pipeline Engineering Design and Installation âĒ New PLEM design, Fabrication and Installation âĒ SPM Piping Modification GLOBAL SCOPE OF WORK

- 6. FLOW CHART FLOW CHART PIPELINE ENGINEERING

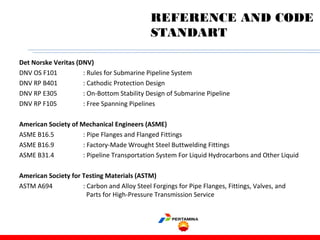

- 7. Det Norske Veritas (DNV) DNV OS F101 : Rules for Submarine Pipeline System DNV RP B401 : Cathodic Protection Design DNV RP E305 : On-Bottom Stability Design of Submarine Pipeline DNV RP F105 : Free Spanning Pipelines American Society of Mechanical Engineers (ASME) ASME B16.5 : Pipe Flanges and Flanged Fittings ASME B16.9 : Factory-Made Wrought Steel Buttwelding Fittings ASME B31.4 : Pipeline Transportation System For Liquid Hydrocarbons and Other Liquid American Society for Testing Materials (ASTM) ASTM A694 : Carbon and Alloy Steel Forgings for Pipe Flanges, Fittings, Valves, and Parts for High-Pressure Transmission Service REFERENCE AND CODE STANDART

- 8. American Petroleum Institute (API) API RP 1111 : Design, Construction, Operation and Maintenance of Offshore Hydrocarbon Pipelines API Spec. 1104 : Standard for Welding Pipeline and Related Facilities API Spec. 5L : Line Pipe API Spec. 6D : Pipeline Valves Manufacturers Standard Society (MSS) MSS SP-75 : Specification for High Test Wrought Buttwelding Fittings National Association of Corrosion Engineers (NACE) NACE Std. MR-0175 : Sulfide Stress Cracking Resistant Metallic Materials for Oilfield Equipment Statutory Regulations 300.K/38/M.PE/1997 : Work Safety of Oil and Gas Pipeline REFERENCE AND CODE STANDART

- 9. FEED â DETAIL DESIGN (ENGINEERING DESIGN) SCOPE : 1. ENGINEERING DESIGN CALCULATION âĒ PIPELINE DESIGN BASIS âĒ PIPELINE FLOW ASSURANCE AND LINE SIZING âĒ PIPELINE MATERIAL AND COATING VERIFICATION âĒ PIPELINE THERMAL EXPANSION ANALYSIS âĒ WALL THICKNESS CALCULATION REPORT âĒ PIPELINE BUCKLING ANALYSIS âĒ EXPANSION SPOLL ANALYSIS âĒ ON-BOTTOM VERTICAL AND LATERAL STABILITY âĒ PIPELINE FREE SPAN ANALYSIS (STATIC & DYNAMIC) âĒ OVALITY ASSESSMENT âĒ CATHODIC PROTECTION DESIGN âĒ PIPE LAYING STRESS ANALYSIS âĒ SPM PLEM FOUNDATION CALCULATION âĒ SUBMARINE HOSE CALCULATION DETAIL SCOPE OF WORK

- 10. FEED â DETAIL DESIGN (ENGINEERING DESIGN) SCOPE : 2. ENGINEERING DATA SHEET âĒ DATA SHEET FOR LINE PIPE âĒ DATA SHEET FOR PIPELINE BEND âĒ DATA SHEET FOR BALL PIPELINE FLANGE CONNECTOR AND PIPELINE FLANGE âĒ DATA SHEET FOR SACRIFICIAL ANODE DETAIL SCOPE OF WORK

- 11. 3. ENGINEERING DRAWING DETAIL SCOPE OF WORK Pipeline Route Alignment Sheet Offshore Pipeline Flow Diagram SBM & FSO Cinta Natomas Layout_Luas Area Pelabuhan Khusus Palang Area Layout P&ID Pig Receiver_Palang Station Piping Arrangement_SPM 1179 Lifting Arrangement & Padeye Detail 10.25 in dia PLEM for FSO Mudmat Layout & Details 10.25 in dia PLEM for FSO Aluminium Anode Layout & Plan 14 inches Pipe PILE Sch-40 Anchor Pile Make-up & Details 48-in Pipe Pile_MakeUp & Details Connection PLEM to SPM Final position of anchor pile-1

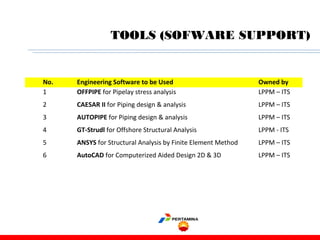

- 12. TOOLS (SOFWARE SUPPORT) No. Engineering Software to be Used Owned by 1 2 3 4 5 6 OFFPIPE for Pipelay stress analysis CAESAR II for Piping design & analysis AUTOPIPE for Piping design & analysis GT-Strudl for Offshore Structural Analysis ANSYS for Structural Analysis by Finite Element Method AutoCAD for Computerized Aided Design 2D & 3D LPPM â ITS LPPM â ITS LPPM â ITS LPPM - ITS LPPM â ITS LPPM â ITS

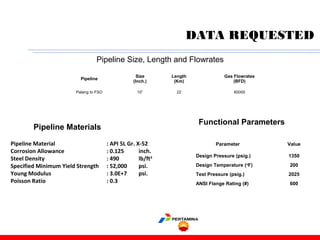

- 13. DATA REQUESTED Pipeline Size (Inch.) Length (Km) Gas Flowrates (BFD) Palang to FSO 10â 22 60000 Pipeline Size, Length and Flowrates Pipeline Material : API 5L Gr. X-52 Corrosion Allowance : 0.125 inch. Steel Density : 490 lb/ft3 Specified Minimum Yield Strength : 52,000 psi. Young Modulus : 3.0E+7 psi. Poisson Ratio : 0.3 Pipeline Materials Parameter Value Design Pressure (psig.) 1350 Design Temperature (o F) 200 Test Pressure (psig.) 2025 ANSI Flange Rating (#) 600 Functional Parameters

- 14. DATA REQUESTED External Corrosion Coating Material : 3LPE 3 Layer External Corrosion Coating Thickness : 0.157 inch. External Corrosion Coating Density : 79.9 lb/ft3 Final Coating Breakdown : 5 % Cathodic Protection Method : Sacrificial Anode Corrosion Protection Lay Barge Name : Arwana[1]) Freeboard Length : 1.8 m Stinger Length : 25 m Barge Tension : 60 tonne Lay Barge Data

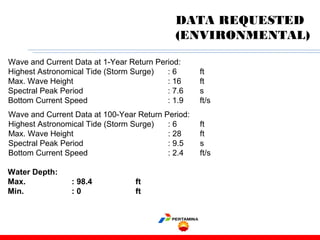

- 15. DATA REQUESTED (ENVIRONMENTAL) Wave and Current Data at 1-Year Return Period: Highest Astronomical Tide (Storm Surge) : 6 ft Max. Wave Height : 16 ft Spectral Peak Period : 7.6 s Bottom Current Speed : 1.9 ft/s Wave and Current Data at 100-Year Return Period: Highest Astronomical Tide (Storm Surge) : 6 ft Max. Wave Height : 28 ft Spectral Peak Period : 9.5 s Bottom Current Speed : 2.4 ft/s Water Depth: Max. : 98.4 ft Min. : 0 ft

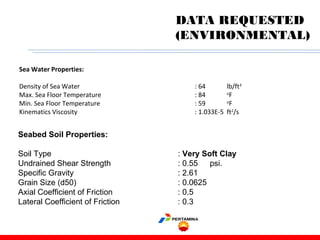

- 16. DATA REQUESTED (ENVIRONMENTAL) Sea Water Properties: Density of Sea Water : 64 lb/ft3 Max. Sea Floor Temperature : 84 o F Min. Sea Floor Temperature : 59 o F Kinematics Viscosity : 1.033E-5 ft2 /s Seabed Soil Properties: Soil Type : Very Soft Clay Undrained Shear Strength : 0.55 psi. Specific Gravity : 2.61 Grain Size (d50) : 0.0625 Axial Coefficient of Friction : 0.5 Lateral Coefficient of Friction : 0.3

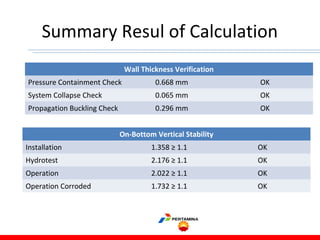

- 17. Summary Resul of Calculation Wall Thickness Verification Pressure Containment Check 0.668 mm OK System Collapse Check 0.065 mm OK Propagation Buckling Check 0.296 mm OK On-Bottom Vertical Stability Installation 1.358 âĨ 1.1 OK Hydrotest 2.176 âĨ 1.1 OK Operation 2.022 âĨ 1.1 OK Operation Corroded 1.732 âĨ 1.1 OK

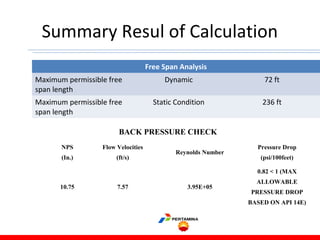

- 18. Summary Resul of Calculation Free Span Analysis Maximum permissible free span length Dynamic 72 ft Maximum permissible free span length Static Condition 236 ft NPS (In.) Flow Velocities (ft/s) Reynolds Number Pressure Drop (psi/100feet) 10.75 7.57 3.95E+05 0.82 < 1 (MAX ALLOWABLE PRESSURE DROP BASED ON API 14E) BACK PRESSURE CHECK

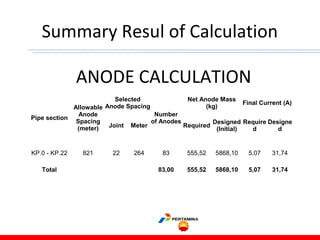

- 19. Summary Resul of Calculation Pipe section Allowable Anode Spacing (meter) Selected Anode Spacing Number of Anodes Net Anode Mass (kg) Final Current (A) Joint Meter Required Designed (Initial) Require d Designe d Ėý Ėý Ėý Ėý Ėý Ėý Ėý Ėý Ėý KP.0Ėý-ĖýKP.22 821 22 264 83 555,52 5868,10 5,07 31,74 Ėý Ėý Ėý Ėý Ėý Ėý Ėý Ėý Ėý Total Ėý Ėý Ėý 83,00 555,52 5868,10 5,07 31,74 ANODE CALCULATION

- 20. Summary Resul of Calculation PIPELINE EXPANSION CALCULATION Kilometer Point of Pipeline Route OD (In.) Virtual Anchor Location [m] Hydro Testing Operating Kp. 0.0 to Kp. 22 10 4143 3980

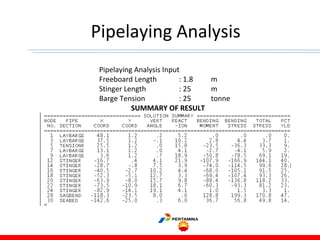

- 21. Pipelaying Analysis Pipelaying Analysis Input Freeboard Length : 1.8 m Stinger Length : 25 m Barge Tension : 25 tonne SUMMARY OF RESULT

![DATA REQUESTED

External Corrosion Coating Material : 3LPE 3 Layer

External Corrosion Coating Thickness : 0.157 inch.

External Corrosion Coating Density : 79.9 lb/ft3

Final Coating Breakdown : 5 %

Cathodic Protection Method : Sacrificial Anode

Corrosion Protection

Lay Barge Name : Arwana[1])

Freeboard Length : 1.8 m

Stinger Length : 25 m

Barge Tension : 60 tonne

Lay Barge Data](https://image.slidesharecdn.com/5145cfc7-79d2-4622-81d0-da866b55b265-160309172114/85/PPEJ-090-2010-rev2-14-320.jpg)

![Summary Resul of Calculation

PIPELINE EXPANSION CALCULATION

Kilometer Point of

Pipeline Route OD

(In.)

Virtual Anchor Location [m]

Hydro Testing Operating

Kp. 0.0 to Kp. 22

10

4143 3980](https://image.slidesharecdn.com/5145cfc7-79d2-4622-81d0-da866b55b265-160309172114/85/PPEJ-090-2010-rev2-20-320.jpg)