PRESENTAZIONE VALERIO D'ANGELO

- 1. 14 NOVEMBRE 2017 HRC, Human Robot Collaboration Valerio DŌĆÖAngelo, Business Development Support

- 2. Human-Robot Collaboration Introducing Yumi Yumi case studies Q&A November 15, 2017 ║▌║▌▀Ż 2 Agenda

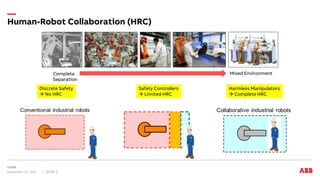

- 3. November 15, 2017 ║▌║▌▀Ż 3 Human-Robot Collaboration (HRC) Complete Separation Mixed Environment Discrete Safety ’āĀ No HRC Safety Controllers ’āĀ Limited HRC Harmless Manipulators ’āĀ Complete HRC

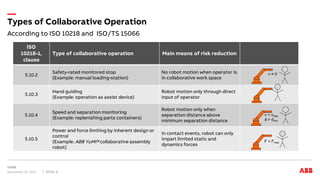

- 4. According to ISO 10218 and ISO/TS 15066 Types of Collaborative Operation November 15, 2017 ║▌║▌▀Ż 4 ISO 10218-1, clause Type of collaborative operation Main means of risk reduction 5.10.2 Safety-rated monitored stop (Example: manual loading-station) No robot motion when operator is in collaborative work space 5.10.3 Hand guiding (Example: operation as assist device) Robot motion only through direct input of operator 5.10.4 Speed and separation monitoring (Example: replenishing parts containers) Robot motion only when separation distance above minimum separation distance 5.10.5 Power and force limiting by inherent design or control (Example: ABB YuMi┬« collaborative assembly robot) In contact events, robot can only impart limited static and dynamics forces

- 5. Economic Background HRC ŌĆō Human Robot Collaboration November 15, 2017 ║▌║▌▀Ż 5 Societal Trend ŌĆō Individuality ŌĆō Differentiation w.r.t. peers Resulting Market Trend ŌĆō Increasing no. of product variants, customization ŌĆō Decreasing product lifetime ŌĆō From ŌĆ£mass productionŌĆØ towards ŌĆ£mass customizationŌĆØ Challenge to Industrial Production ŌĆō Efficient handling of large range of variants and short model lifetimes ŌĆō Common solution today: Mostly manual production in Asia Volume on # Variants Manual Production volume per variant No.ofproductvariantsLoHi Lo Hi Hard automation Conventional robot applications

- 6. Productivity HRC ŌĆō Human Robot Collaboration November 15, 2017 ║▌║▌▀Ż 6 Considering a defined item the used technology is depending on the required volume. Using HRC can reduce the unit costs in case of medium /low volumes . HRC can create new opportunity in investment on automation. The increasing of labor cost can increase the area of HRC application Volume on unit cost

- 7. Overview Introducing YuMi November 15, 2017 ║▌║▌▀Ż 7 No barriers No cages No zones YuMi is the first truly collaborative robot solution Differentiated Value proposition

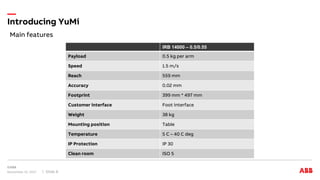

- 8. November 15, 2017 ║▌║▌▀Ż 8 Introducing YuMi IRB 14000 ŌĆō 0.5/0.55 Payload 0.5 kg per arm Speed 1.5 m/s Reach 559 mm Accuracy 0.02 mm Footprint 399 mm * 497 mm Customer interface Foot interface Weight 38 kg Mounting position Table Temperature 5 C ŌĆō 40 C deg IP Protection IP 30 Clean room ISO 5 Main features

- 9. November 15, 2017 ║▌║▌▀Ż 9 Introducing YuMi Working range

- 10. Integrated controller Introducing YuMi November 15, 2017 ║▌║▌▀Ż 10 Saves working space Better cell layout Equipment can be placed closer to, or around, robot without interference Robot is more streamlined and easy to relocate No floor cables or control cables Integrated controller

- 11. Padded Arms Introducing YuMi November 15, 2017 ║▌║▌▀Ż 11 Adds to safety of operators if there is an unlikely contact during operation The robot can be run faster due to added protection Faster robot means the ROI will be greater Padded Arms

- 12. ESD Protection Introducing YuMi November 15, 2017 ║▌║▌▀Ż 12 It is possible to manipulate electronic components without damage them due to the Electrostatic Discharge (ESD) protection ESD Protection

- 13. Safety Certification Introducing YuMi November 15, 2017 ║▌║▌▀Ż 13 Safety Certification No need to certify the robot Can be included in your risk assessment of the cell Independent body has certified the robot PL b Cat b

- 14. PFL-Power and Force Limiting Safety Discussion November 15, 2017 ║▌║▌▀Ż 14 Inherently safe by design Mechanical measures Lightweight arms Padding No pinch points Back-drivable brakes Controller Safety Functions Protective stop with PL=b Supervised speed at hand and elbow with max. 1500 mm/s (PL=b) Collision detection

- 15. Easy Programming Introducing YuMi November 15, 2017 ║▌║▌▀Ż 15 Lead-Through Programming Lead-Through Programming makes the programming easy Integrated vision can pick unsorted parts Tablet programming can be wireless saving the need for wires Standard IRC5 rapid as other ABB robots

- 16. Easy Programming Introducing YuMi November 15, 2017 ║▌║▌▀Ż 16

- 17. Customer Benefits Introducing YuMi November 15, 2017 ║▌║▌▀Ż 17 Integrated Hand No need to design your own hand Multi-option hand with five options Integrated communications and air Servo Vacuum Camera

- 18. Customer Benefits Introducing YuMi November 15, 2017 ║▌║▌▀Ż 18 Integrated Vision Cameras embedded in gripper Integrated hands makes it possible to use the hand for vison guided Can be used for simple inspection

- 19. Main Markets Introducing YuMi November 15, 2017 ║▌║▌▀Ż 19 Collaborative Assembly Camera-based inspection and assembly Accurate and fast assembly Testing and packaging Collaborative Assembly Camera-based inspection and assembly Accurate and fast assembly Testing and packaging Collaborative Assembly (Plastic parts etc.) Packaging of small goods Multifunction hand for add components Collaborative Assembly Use of feeding and vision options Automotive General Industry Electronics Medicals

- 20. Summing Up Introducing YuMi November 15, 2017 ║▌║▌▀Ż 20 Dual Arm Safe and collaborative No cages needed Padded arms and light weight design Speed limited Increased ROI fast accurate assembly, lower maintenance costs Ease-of-integration Wide range of communcations interfaces Integrated hand equipped with vision Integrated controller Light weight and portable Ease-of-use Lead-Through Programming

- 21. Applications Automotive Assembly November 15, 2017 ║▌║▌▀Ż 21 Inspection through Integrated Vision Cameras embedded in gripper Easy to deploy Collaborative and flexible inspection

- 22. Applications Automotive Assembly November 15, 2017 ║▌║▌▀Ż 22 FlexFeeder ŌĆō Vision and Parts Insertion Dual Arm Coordinated Robot accuracy Integrated Vision FlexFeeder

- 23. Applications Automotive Assembly November 15, 2017 ║▌║▌▀Ż 23 Parts Placement and Pre-screw Parts placement HRC-based application Pre-screwing on part Accurate and compact

- 24. Inherently safe by design Safety Discussion November 15, 2017 ║▌║▌▀Ż 24

Editor's Notes

- #7: Qui vediamo il costo unitario di produzione in funzione dei volumi di produzione. Il costo unitario nel caso dellŌĆÖassemblaggio manuale ├© indipendente dal volume di produzione, poich├© ├© il costo della forza lavoro dellŌĆÖessere umano. Quindi, fissato un volume di produzione, la curva che si incontra prima dal basso verso lŌĆÖalto rappresenta la soluzione industriale pi├╣ conveniente. LŌĆÖaumento del costo della manodopera accresce i campi di applicabilit├Ā delle applicazioni HRC!