Process Improvement Presentation V1

- 1. Performance Improvement that Makes a Difference Presented by: Michael Peterson, PHR

- 2. TodayÔÇÖs Agenda ÔÇó Introduction to Sharp ÔÇó Are you ready for a process improvement initiative? ÔÇó Introduction to Six Sigma ÔÇó What is LEAN vs. Six Sigma ÔÇó Results ÔÇó Questions

- 3. Sharp HealthCare ÔÇó San DiegoÔÇÖs Health Care Leader ÔÇó Not-for-profit ÔÇó Largest health care system in San Diego ÔÇô 4 Acute Care Hospitals ÔÇô 3 Specialty Hospitals ÔÇô 2 Affiliated Medical Groups ÔÇô Full range of programs and services ÔÇó Largest private employer in San Diego ÔÇô 15,000 Employees ÔÇô 2,600 Affiliated Physicians ÔÇô 2,000 Volunteers

- 5. Are you ready? ÔÇó Foundational elements of process improvement ÔÇô Often overlooked ÔÇô Leads to the failure of many, if not most, process improvement initiatives

- 6. Are you ready? ÔÇó Define ÔÇô What is the true problem? Baseline measures ÔÇô What does success look like? ÔÇô How will it be measured? ÔÇó Assess ÔÇô What is the driver for improvement? ÔÇó Internal to the department ÔÇó External, but within the company ÔÇó External from the company ÔÇó A mix?

- 7. Are you ready? ÔÇó Assess ÔÇô How will you sustain the gains/improvements? ÔÇó Policy and procedural changes ÔÇó Audits ÔÇô How ÔÇô What resources ÔÇô Who ÔÇó Incentives ÔÇô What kind? ÔÇô Unintended consequences

- 8. Are you ready? ÔÇó Assess ÔÇô Are your processes stable? ÔÇó It is impossible to improve any process that is not consistent ÔÇô The Toyota Way ÔÇô Is anything ÔÇ£hidingÔÇØ problems ÔÇó The Toyota Way ÔÇô Batch manufacturing

- 9. Are you ready? ÔÇó Assess ÔÇô Is anything ÔÇ£hidingÔÇØ problems (continued) ÔÇó What may be hiding problems in Recruiting? ÔÇô Success ÔÇô Brand ÔÇô Lack of competition ÔÇô Lack of need ÔÇô Candidate database ÔÇô Apathy ÔÇô Unrealized problem(s) ÔÇô Lack of knowledge of a better state

- 10. Are you ready? ÔÇó Assess ÔÇô Do you have the resources? ÔÇó People- everyone is accountable ÔÇó Money ÔÇó Time ÔÇô What are the obstacles? ÔÇó Can we mitigate them?

- 11. Six Sigma and LEAN

- 12. What is Six Sigma? ÔÇó A methodology that focuses on data-driven decisions ÔÇó Reduction in variation ÔÇó A statistical term that represents near-perfection ÔÇó A philosophy of driving results to levels never before expected

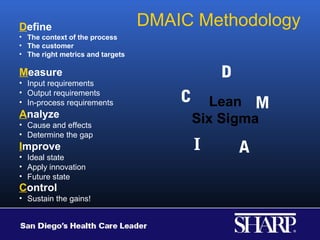

- 13. Define DMAIC Methodology ÔÇó The context of the process ÔÇó The customer ÔÇó The right metrics and targets Measure ÔÇó Input requirements D ÔÇó Output requirements ÔÇó In-process requirements C Lean M Analyze ÔÇó Cause and effects Six Sigma ÔÇó Determine the gap Improve I A ÔÇó Ideal state ÔÇó Apply innovation ÔÇó Future state Control ÔÇó Sustain the gains!

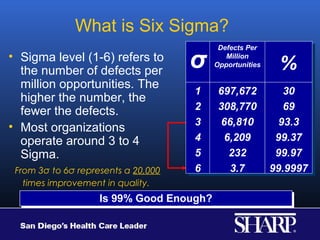

- 14. What is Six Sigma? Defects Per ¤â Defects Per ÔÇó Sigma level (1-6) refers to the number of defects per ¤â Million Million Opportunities Opportunities % % million opportunities. The 1 1 697,672 697,672 30 30 higher the number, the fewer the defects. 2 2 308,770 308,770 69 69 3 3 66,810 66,810 93.3 93.3 ÔÇó Most organizations operate around 3 to 4 4 4 6,209 6,209 99.37 99.37 Sigma. 5 5 232 232 99.97 99.97 From 3¤â to 6¤â represents a 20,000 6 6 3.7 3.7 99.9997 99.9997 times improvement in quality. Is 99% Good Enough? Is 99% Good Enough?

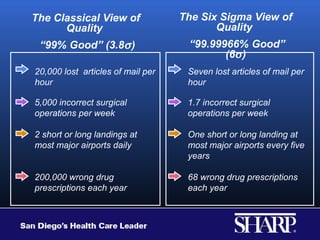

- 15. The Classical View of The Six Sigma View of Quality Quality ÔÇ£99% GoodÔÇØ (3.8¤â ) ÔÇ£99.99966% GoodÔÇØ (6¤â ) 20,000 lost articles of mail per Seven lost articles of mail per hour hour 5,000 incorrect surgical 1.7 incorrect surgical operations per week operations per week 2 short or long landings at One short or long landing at most major airports daily most major airports every five years 200,000 wrong drug 68 wrong drug prescriptions prescriptions each year each year

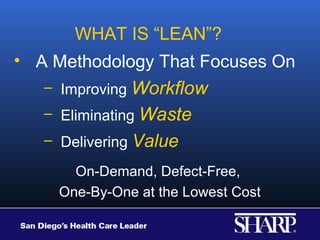

- 16. WHAT IS ÔÇ£LEANÔÇØ? ÔÇó A Methodology That Focuses On ÔÇô Improving Workflow ÔÇô Eliminating Waste ÔÇô Delivering Value On-Demand, Defect-Free, One-By-One at the Lowest Cost

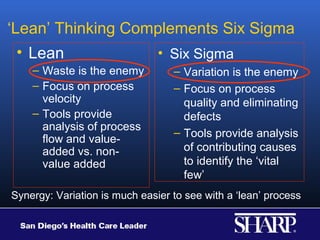

- 17. ÔÇÿLeanÔÇÖ Thinking Complements Six Sigma ÔÇó Lean ÔÇó Six Sigma ÔÇô Waste is the enemy ÔÇô Variation is the enemy ÔÇô Focus on process ÔÇô Focus on process velocity quality and eliminating ÔÇô Tools provide defects analysis of process ÔÇô Tools provide analysis flow and value- added vs. non- of contributing causes value added to identify the ÔÇÿvital fewÔÇÖ Synergy: Variation is much easier to see with a ÔÇÿleanÔÇÖ process

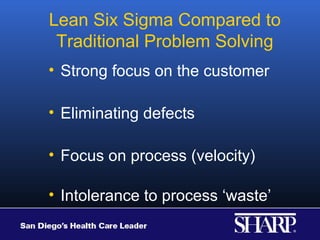

- 18. Lean Six Sigma Compared to Traditional Problem Solving ÔÇó Strong focus on the customer ÔÇó Eliminating defects ÔÇó Focus on process (velocity) ÔÇó Intolerance to process ÔÇÿwasteÔÇÖ

- 19. Results

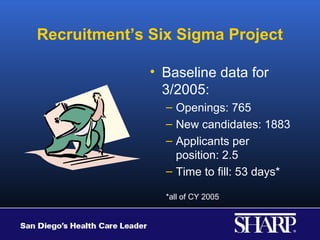

- 20. RecruitmentÔÇÖs Six Sigma Project ÔÇó Baseline data for 3/2005: ÔÇô Openings: 765 ÔÇô New candidates: 1883 ÔÇô Applicants per position: 2.5 ÔÇô Time to fill: 53 days* *all of CY 2005

- 21. Results ÔÇó Measurable improvements ÔÇô Number of open positions ÔÇó March 2005: 765 ÔÇó March 2010: 343 ÔÇó Reduction: 55%

- 22. Results ÔÇó Measurable improvements ÔÇô Time to fill ÔÇó CY 2005: 53 days ÔÇó CY 2009*: 36 days ÔÇó Reduction: 32% *Through June 2009

- 23. Results ÔÇó Measurable improvements ÔÇô New applicants ÔÇó March 2005: 1883 ÔÇó March 2010: 2578 ÔÇó Increase: 36.9% ÔÇó Peaked September 2010: 3925 or a 108.4% increase

- 24. Results ÔÇó Measurable improvements ÔÇô Applicants per posting ÔÇó March 2005: 2.5 ÔÇó April 2010: 5.2 ÔÇó Increase: 108% ÔÇó Peaked January 2010: 9.6 or a 284% increase

- 25. Results ÔÇó Measurable improvements ÔÇô Reduced expenses on interim staffing ÔÇó FY 2004 Registry: $6,103,294 ÔÇó FY 2008 Registry: $2,875,774 ÔÇó Reduction: $3,227,520 or 52.9%

- 26. Results ÔÇó Measurable improvements ÔÇô Reduced expenses on interim staffing ÔÇó FY 2004 Registry Hours: 114,989 ÔÇó FY 2008 Registry Hours: 52,157 ÔÇó Reduction: 54.6%

- 27. Results ÔÇó Measurable improvements ÔÇô Reduced expenses on interim staffing ÔÇó FY 2004 Traveler Hours: 292,273 ÔÇó FY 2008 Traveler Hours: 190,137 ÔÇó Reduction: 34.9%

- 28. Results ÔÇó Measurable improvements ÔÇô New hire performance improvements* ÔÇó FY 2004 vs. FY 2005: 15.3% increase ÔÇó FY 2004 vs. FY 2006: 23.1% increase ÔÇó FY 2004 vs. FY 2007: 20.5% increase ÔÇó FY 2004 vs. FY 2008: 23.1% increase

- 29. Results ÔÇó Non-measurable improvements ÔÇô Improved approach to managing expenses ÔÇó Media ÔÇó Events ÔÇó Other ÔÇô Improved approach to investigating new media, technologies and practices

- 30. Results ÔÇó Non-measurable improvements ÔÇô More confidence working with the hiring managers ÔÇó Improved relationships ÔÇó More comfortable ÔÇ£providing inputÔÇØ ÔÇó More comfortable innovating

- 31. Results ÔÇó Non-measurable improvements ÔÇô Expedited a culture of more accountability ÔÇó Within Recruitment ÔÇó Outside of Recruitment

- 32. Questions? Contact Information: E-mail: michael.peterson@sharp.com Social Media- Opinions expressed are my own LinkedIn: http://www.linkedin.com/in/michaelkpeterson Twitter: @SoCalRecruiting Blog: SoCalRecruiting.wordpress.com

Editor's Notes

- #4: MP TO PUT OUR STORY INTO PERSPECTIVE, LET ME TAKE A MOMENT TO PROVIDE YOU A VERY BRIEF OVERVIEW OF THE SHARP HEALTHCARE ORGANIZATION. SHARP IS A NOT-FOR-PROFIT, FULLY INTEGRATED HEALTH CARE SYSTEM SERVING THE ENTIRE COUNTY OF SAN DIEGO FOR OVER FIFTY YEARS.. And for our last polling question, please let us know what industry you work in

- #5: MP TO PUT OUR STORY INTO PERSPECTIVE, LET ME TAKE A MOMENT TO PROVIDE YOU A VERY BRIEF OVERVIEW OF THE SHARP HEALTHCARE ORGANIZATION. SHARP IS A NOT-FOR-PROFIT, FULLY INTEGRATED HEALTH CARE SYSTEM SERVING THE ENTIRE COUNTY OF SAN DIEGO FOR OVER FIFTY YEARS.. And for our last polling question, please let us know what industry you work in

- #6: MP Start of many process improvement initiatives: Things ÔÇ£need to be better, or improveÔÇØ But this critical step is often overlooked and leads to failure How many times have you been part of a ÔÇ£process improvement initiativeÔÇØ only to see all those efforts either: Result in improvement that is short lived Or drift to a state of marginal improvement This is because of our eagerness to get the work done without thinking of where we are and where we are going Would you start a long journey with no idea where you are and where you are headed?

- #7: MP How to determine where you are and where you are headed: Define where you are by: Looking at what the problems are, accept that you may not know the causes yet Determine how things will be measured, again accept that you may add to these measures Conduct baseline measures, this will later help you measure effectiveness Determine what success looks like by: Listening to the voice of the customer, what you want usually doesnÔÇÖt matter, what they want does Job seeker example GM example Defining what successful measures will be: Better time measures (be careful) Better cost measures (be careful) Better quality measures Better outcomes Anecdotal measures The definition of success may be partially defined by the driver for improvement For example, if your customers are saying quality is too low, you wouldnÔÇÖt necessarily focus on cost savings

- #8: MP Sustaining the gains/improvements are one of the areas that many projects fail: We all have examples from our experience of those projects that improve performance for a short time, but them everyone slowly returns to their old ways Early on or in some cases before starting the project, look at the tools that you have to make the improvement sustainable and review any ÔÇ£infrastructureÔÇØ like policies and procedures that may need to be changed. If policies and procedures need to be changed, you will need to build into your plan the necessary steps based on your organization. Approvals from sr. leadership, committees, etc. Impact on other departments that utilize/are governed by the same policy/procedure Input and buy in from customers For example: if you are changing the service delivery model, you want input from those that receive the service Do you use audits? (how, what resources do you have, who would do it, what is the enforcement mechanism) Incentives? (what kind, how do you fund?) Watch for unintended consequences

- #9: MP It is impossible to improve any process that is not consistent from the Toyota Way Process improvement is difficult enough with one process, let alone 5 processes that are inconsistent and vary from person to person So ask your self, are your processes stable? If they are, then you can proceed with the initiative If they are not, this makes things very difficult How do you do a baseline measure? Are the variable processes the cause of the issue? Work to create one process and see what the impact is You may still be able to measure a baseline, but it would probably need to be something like customer satisfaction Also be prepared to accept that part of your processes/infrastructure may be hiding problems In Toyota Way one manufacturing process that hides problems is traditional ÔÇ£batchÔÇØ manufacturing where a large supply of parts is made, but that has an unintended consequence of hiding inefficiencies in planning and production

- #10: MP Here are some examples of things within Recruiting that would potentially hide problems

- #11: MP Finally before starting: Assess if you have the resources necessary, this is another point of failure or at least delay for projects Identify other obstacles and proactively try to find a way to mitigate them Buy in from someone that is hard to convince Cooperation from another department Systems and processes that would not support change or need to be worked around

- #13: Many of the elements of Six Sigma and touched upon in The Toyota Way To be honest, I didnÔÇÖt read Toyota Way until after the Six Sigma Project was complete and realized that some of the concepts in the book were ones that we utilized and explored as part of our project

- #14: I have taken you through some of these earlier, specifically Defining and Control To Measuring on this slide I would add a baseline measure to establish a means by which to measure progress

- #16: Who functions at a Six Sigma level? Airplane industryÔǪthinking about landings. Six sigma focuses on reducing variability, it does not much matter where ÔÇô could be very useful in these businesses as well. 3 ´ü│ capabilityÔÇöhistorical standard 4 ´ü│ capabilityÔÇöcurrent standard 6 ´ü│´Çá capabilityÔÇönew standard We must deliver every project, product, or service with the highest quality. In todayÔÇÖs marketplace, ÔÇ£goodÔÇØ is no longer good enough. The experience of several world class companies which have dramatically improved quality levels using the Six Sigma method has demonstrated that: We can be much better if we take a rigorous approach to quality improvement. Six Sigma means: A 99.99966% probability that we will not pass on a defect to the customer.

- #22: March 2005 was as far back as I could go WeÔÇÖre a big organization with a lot of moving parts, so obviously these improvements are the result of many initiatives, some of which were part of or resulted from six sigma, but some were independent or even beyond our control

- #23: MP

- #24: MP Applicant volume increases started small in July 2005 and kept growing stronger and stronger with some fluctuation

- #25: MP We started tracking applicants per posting because we recognized the number of postings declining and felt that this decline would eventually impact the volume of applicants, which is something that we may be seeing today.

- #26: MP For those of you outside of healthcare, Registry is something like a last minute temporary employee they come in to cover for a shorter period of time, usually for unplanned absences Having additional available staff and a strong internal temp pool can mitigate the need for external registry We also implemented an internal system that allows employees to bid on available shifts for coverage

- #27: MP Dramatic reduction in Registry Hours

- #28: MP The reason I did not share cost with you is the number was deceptive. The underlying structure of how we worked with Travelers changed completely since FY 2004 and the per hour rate increased dramatically as a result.

- #29: MP So getting to the focus of this presentations title, these are the results we have for quality of hire We measured quality of hire for the purpose of this presentation by comparing average merit increases for individuals hired on or after FY 2004 FY 2004- before the Six Sigma Project This slide reflects the percent increase in average merit increase since the FY 2004, not the actual increase to salary Quality of hire is the result of a process As you can see, Six Sigma is a great tool/methodology for reviewing and improving processes So look at where you are, and where you want to be: The D in DMAIC stands for Define, so define what a high quality hire is. Is it mgr satisfaction, performance, cultural integration, team integration, new hire satisfaction, is it multi-dimensional? What time frames are critical? Then decide if a Six Sigma process is what you need to make the improvements necessary. Look at the variability, determine what is driving it and fix it. Keep asking why throughout the process? The C in DMAIC stands for control and that is the true key- building a sustainable fix.

- #30: MP I feel that the non-measurable improvements are the true benefits and the measurements are the outcome of those improvements Being data driven, being more confident in moving forward with new technologies You have a comfort with data going in You have a comfort with data to evaluate efficacy

- #31: MP Communication improves relationships Armed with data and experience, we are more comfortable providing input to managers More comfortable innovating

- #32: MP Throughout the talent supply chain, more accountability Perfect- no Better- yes

- #33: MP My contact information is: [email_address] Also on LinkedIn and Twitter I also have a blog: socalrecruiting.wordpress.com