Processing and analysis of ground spices.. (turmeric

- 1. Processing and analysis of ground spices (turmeric) Presented by : Mohmmad Idrees Attar Presented to : Dr. R. M Shukla Reg No.: 166 Division of Agricultural Engineering, SKUAST-K

- 2. Introduction ’é┤ Turmeric (Curcuma longa) (Family: Zingiberaceae) is used as condiment, dye, drug and cosmetic in addition to its use in religious ceremonies. ’é┤ India is a leading producer and exporter of turmeric in the World. ’é┤ Andhra Pradesh, Tamil Nadu, Orissa, Karnataka, West Bengal, Gujarat, Meghalaya, Maharashtra, Assam are some of the important states cultivates turmeric ’é┤ Andhra Pradesh alone occupies 35.0% of area and 47.0 per cent of production ’é┤ During 2006-2007, the country produced 8,37,200 tons of turmeric from an area of 1,86,000 ha. About Turmeric

- 4. Images

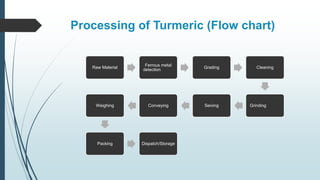

- 5. Processing of Turmeric (Flow chart) Raw Material Ferrous metal detection Grading Cleaning GrindingSeivingConveyingWeighing Packing Dispatch/Storage

- 7. Layout

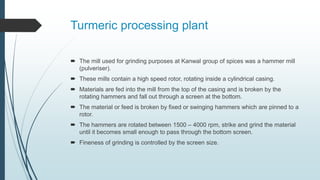

- 10. Turmeric processing plant ’é┤ The mill used for grinding purposes at Kanwal group of spices was a hammer mill (pulveriser). ’é┤ These mills contain a high speed rotor, rotating inside a cylindrical casing. ’é┤ Materials are fed into the mill from the top of the casing and is broken by the rotating hammers and fall out through a screen at the bottom. ’é┤ The material or feed is broken by fixed or swinging hammers which are pinned to a rotor. ’é┤ The hammers are rotated between 1500 ŌĆō 4000 rpm, strike and grind the material until it becomes small enough to pass through the bottom screen. ’é┤ Fineness of grinding is controlled by the screen size.

- 11. Packing of ground powder ’é┤ The packaging unit at the Kanwal group of spices comprised 3 main machines Figure 1: Pakona-500gm packing Figure 2: Auger Filler-1kg packing Figure 3: Pakona-100&200gm packing

- 12. QUALITY ANALYSIS TESTS The parameters for which the quality was examined in contrast to the Agmark specifications are: ’é┤Moisture Content ’é┤Total Ash ’é┤Acid insoluble ash ’é┤Non-volatile ether extraction ’é┤Volatile oil

- 13. Agmark standards for Turmeric powder:

- 14. Observations ’é┤ The moisture content of a ground powder sample of turmeric randomly selected from the production unit of Kanwal group of spices came out to be 7%. ’é┤ The total ash content of ground powder sample of turmeric randomly selected from the production unit of Kanwal group of spices came out to be 4.94%. Moisture content: Total Ash: ’é┤ The acid insoluble ash of ground powder sample of turmeric randomly selected from the production unit of Kanwal group of spices came out to be 0.25%. Acid Insoluble Ash:

- 15. BENEFITS ’āśUsed In Pharmaceutical Industry. ’āśUsed In Food Industry. ’āśUsed In Cosmetic Industry. ’āśOthers (including dye-sensitized PV technology and textiles)

- 16. USES OF TURMERIC (CURCUMIN)

- 17. Thank you