Process-Safety-Management-webinar-PPT.pdf

- 1. Process Safety Management By Sh. V. Narasimhan Conducted by Institution of Safety Engineers (India) www.iseindia.in

- 2. Institution of Safety Engineers (India) Welcome in Free Webinar Session on 20 July 2021, 3:00 PM to 4:15 PM ISE (India) PROCESS SAFETY MANAGEMENT

- 3. About us Institution of Safety Engineers (India) is Non - Profitable organization set up in year 2012 under ZJEW Trust, Govt. Reg. No. 5240 and working with objective to prevent accident, protect environment & minimize losses during disaster. Institution of safety engineers (India) imparting safety, health, environment & quality related training to needy & provide similar services to industries, organization, institution to achieve zero harm. ISE (India) INSTITUTION OF SAFETY ENGINEERS (INDIA) Process Safety Management

- 4. ISE (India) JOURNAL PUBLICATION MEMBERSHIP SERVICES SAFETY HEALTH ENVIRONMENT RELATED TRAINING & SERVICES

- 5. ISE (India) WWW.ISEINDIA.IN OUR SPEAKER Miss Tamanna Afroz : B.Tech, PDIS, SMISE Co-ordinator, Institution of Safety Engineers (India) Mr. V. Narsimhan: Expert in Process Safety Management and Chemical Engineering & Senior Member of Institution of Safety Engineers (India)

- 6. Course Outline ŌĆó Lesson 1 ŌĆó HISTORY ŌĆó Lesson ŌĆó INTRODUCTION ŌĆó Lesson 3 ŌĆó OBJECTIVE ŌĆó Lesson 4 ŌĆó PROCESS SAFETY MGT. ISE (India) WWW.ISEINDIA.IN 1 2 3 4 ŌĆó Lesson 5 ŌĆó ELEMENT OF PROCESS SAFETY MANAGEMENT ŌĆó CASE STUDY ŌĆó Lesson 7 ŌĆó CONCLUSION ŌĆó Lesson 8 ŌĆó QUESTION & ANSWER 5 6 8 7

- 7. OSHA- History In 1912 the first Industrial Revolution took place and a lot of accidents happened and gases emancipating from chimneys and faulty machines were installed. Due to that lots of people died and were not noticed. *Then the World War 1 came in 1914 and ended in 1919 because of that nothing could be done to prevent accidents and death immediately the second industrial revolution came in 1925, then the same story of people dying due to hot gases and faulty machines. People suffered enormously due to the and carried at the waters of the factory and the government in Europe in Britain income came the second world war between 1939 to 1945 nothing could be materialized recording safety. People were educated and wanted to do something costly to ward injury and death due to accidents. * Then came the clean air act amendment in the US in the year 1970 to avoid pollution and other steps. Then the Bhopal incident in India caused 2000 deaths and the Texas blast killed 123 people and three mile disaster and formed OSHA. *Lot of inquiries were made and a lot of discussions were made between 1990 and 1992 in Washington D.C OSHA was conceived. At last they made it compulsory and mandatory for all industries in the U.S and in Europe and Britain and the gulf countries. In the Process Safety Management System under which 14 elements initially and then later 17 elements are now. ISE (INDIA)

- 8. FOR CATASTROPHIC CONSEQUENCES IN THE WORKPLACE

- 9. ISE (India) ISE (INDIA) Introduction About Process Safety Management Risk: Main specific effect with specific of due to the complex of probability and consequence of vulnerability. E.G going in a highway in a car, a man crisscrosses, in order to avoid him if you try to steer your wheel to the right or left to escape from the rat or otherwise get injured in the process. Risk and safety are brothers and sisters. If you have safety in force you can avoid risk. Environment means free pollution from air. E.g. Delhi is a polluted city and prevention is bacon being taken to water pollution. Hazard means which can be of anything or change whether it is a physical hazard or chemical hazard. E.G. Lots of gases are operating from the chimneys and should be controlled. What is safety: Safety is a relative freedom from diseases, fire and flood or by any other means or accidents. E.g.:When you walk on on the road payment, suppose you trip and fall on the payment it is the personal safety.

- 10. OBJECTIVE ’āś Creating awareness among employees & Professional ’āś Developing Positive Behavior among people to Control Process industries related risk ’āś To identify Process Hazard ’āś To Prevent any Potential of Adverse effect ’āś Increase organization Reputation & Success of Business ’āś Fulfill Legal requirements

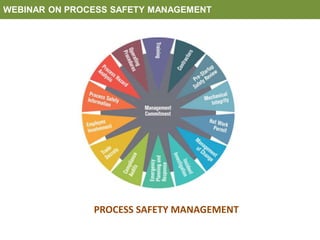

- 11. WEBINAR ON PROCESS SAFETY MANAGEMENT PROCESS SAFETY MANAGEMENT

- 12. Develop on return safety information identifying workplace chemical process hazards, equipment used in the process and Technology as well. Perform your workplace as odd as a statement including identification of potential reasons of accidental release that had a potential 1.THE PROBLEM

- 13. Establish a system for respect to the workplace hazard assessment findings which shall present address prevention mitigation and emergency responses. Review the hazard assessment and response system. To understand PSM and its requirements employees and employers are hard to understand how OSHA uses the term process to mean any actuary involving a highly hazardous chemical. ISE (India) www.iseindia.in 2. HOW THE STANDARD WORK

- 14. ’āśEmployers complete a compilation of written process safety information. ’āśBefore conducting any process by the standard. ’āśInformation on the hazards of the highly hazardous chemical. ’āśInformation about the technology of the process. ’āśInformation on the equipment. ISE (India) www.iseindia.in 3. PROCESS SAFETY INFORMATION

- 15. The employer must the following methods ’āś Hazard and operability study. ’āś Failure mode effect analysis. ’āś Fault tree analysis ISE (India) www.iseindia.in 4. PROCESS HAZARD ANALYSIS The process hazard analysis a thorough , orderly, systematic approach for For identifying involving highly hazardous chemicals

- 16. ’ü▒ Initial startup ’ü▒ Operating operations ’ü▒Temporary operations ’ü▒ Emergency operations ISE (India) www.iseindia.in 5. OPERATING PROCEDURES The employer must develop important return operating procedures.

- 17. ’āś Employers must develop a written plan of action to implement the employers vision ’āś Participation required by PSM. They should provide employees and their. ’āś Representatives access to process-based analysis and knowledge. ISE (India) www.iseindia.in 6. EMPLOYEES PARTICIPATION Employee participation help to control process related risk

- 18. ’āś OSHA believes that the implementation of an effective training program is one. ’āśone of the important steps to take and hence presently involved in operations. ’āś People should know about the process and its procedures. ’āśThat employees have the required to operate the plant and its operating procedures. ISE (India) www.iseindia.in 7.TRAINING

- 19. Refresher training has to be given to every employee at least every three years. ISE (India) www.iseindia.in 8. REFRESHER TRAINING

- 20. ’āś Record card of the employee must be containing their identity ’āś Of the employee, the date of training and how the employee as verified ’āś That the employee understood the training ISE (India) www.iseindia.in 9. TRAINING DOCUMENTATION

- 21. Employees may be present at a particular site and they should know all the procedures and processes of the particular plant. ISE (India) www.iseindia.in 10. CONTRACTORS They should undergo PSM then only in case of emergency crisis they can be utilised.

- 22. ’ü▒ Contractor employer should evaluate obtain information regarding ’ü▒ Contract employees safety performance. ISE (India) www.iseindia.in 11. EMPLOYEES RESPONSIBILITIES

- 23. Construction and equipment are in accordance with design specification . ISE (India) www.iseindia.in 12. PRE- STARTUP SAFETY REVIEW Safe operation, emergency procedures are in place. Construction and equipment or in accordance with design specification. Safe operation, maintenance and emergency procedures are in place.

- 24. OSHA village it is important to the mechanical integrity of the process to maintain the process equipment and to ensure it is and installed correctly designed and operates properly. ISE (India) www.iseindia.in 13. MECHANICAL INTEGRITY

- 25. ’āś Hot permit should be issued for a hot permit operation conducted on an overhead process. ISE (India) www.iseindia.in 14. HOT WORK PERMIT ’āśThe permit must dominate fire protection etc represents in OSHA ’āś Regulations have been implemented prior to the hot work permit system. English

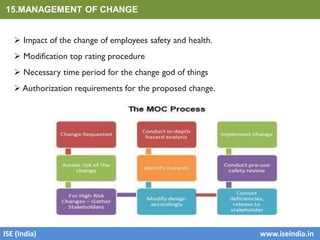

- 26. ’āś Impact of the change of employees safety and health. ’āś Modification top rating procedure ’āś Necessary time period for the change god of things ’āś Authorization requirements for the proposed change. ISE (India) www.iseindia.in 15.MANAGEMENT OF CHANGE

- 27. ’āś Date of incident. ’āś Date of Investigation began ’āś Description of the incident ’āś Description of the incident ’āś Factors contributing to the accident and Recommendation from the investigation. ISE (India) www.iseindia.in 16. INCIDENT INVESTIGATION

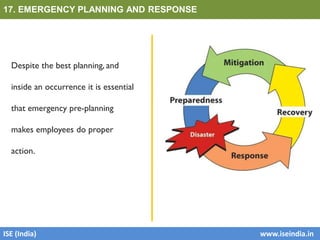

- 28. Despite the best planning, and inside an occurrence it is essential that emergency pre-planning makes employees do proper action. ISE (India) www.iseindia.in 17. EMERGENCY PLANNING AND RESPONSE

- 29. Employees must certify and evaluate with the provision of PSM at least three years. ISE (India) www.iseindia.in 18.COMPLIANCE AUDIT

- 30. ISE (India) www.iseindia.in WEBINAR PROCESS SAFETY MANAGEMENT Any Question

- 31. ISE (India) www.iseindia.in WEBINAR ON PROCESS SAFETY MANAGEMENT THANK YOU! Reference: OSHA, ISEI Manuals & other online sources