Bio-Pesticide Product Costing Template (Pilot Plant Scale Production April 2006)

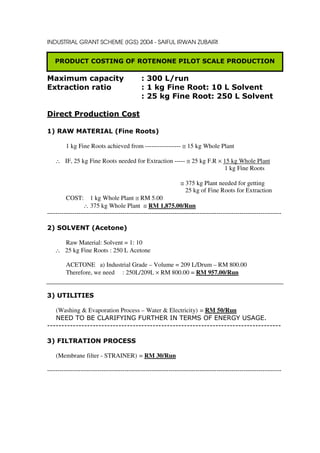

- 1. INDUSTRIAL GRANT SCHEME (IGS) 2004 - SAIFUL IRWAN ZUBAIRI PRODUCT COSTING OF ROTENONE PILOT SCALE PRODUCTION Maximum capacity : 300 L/run Extraction ratio : 1 kg Fine Root: 10 L Solvent : 25 kg Fine Root: 250 L Solvent Direct Production Cost 1) RAW MATERIAL (Fine Roots) 1 kg Fine Roots achieved from ----------------- тЙЕ 15 kg Whole Plant тИ┤ IF, 25 kg Fine Roots needed for Extraction ----- тЙЕ 25 kg F.R ├Ч 15 kg Whole Plant 1 kg Fine Roots тЙЕ 375 kg Plant needed for getting 25 kg of Fine Roots for Extraction COST: 1 kg Whole Plant тЙЕ RM 5.00 тИ┤ 375 kg Whole Plant тЙЕ RM 1,875.00/Run ---------------------------------------------------------------------------------------------------------------- 2) SOLVENT (Acetone) Raw Material: Solvent = 1: 10 тИ┤ 25 kg Fine Roots : 250 L Acetone ACETONE a) Industrial Grade тАУ Volume = 209 L/Drum тАУ RM 800.00 Therefore, we need : 250L/209L ├Ч RM 800.00 = RM 957.00/Run 3) UTILITIES (Washing & Evaporation Process тАУ Water & Electricity) = RM 50/Run NEED TO BE CLARIFYING FURTHER IN TERMS OF ENERGY USAGE. ---------------------------------------------------------------------------------- 3) FILTRATION PROCESS (Membrane filter - STRAINER) = RM 30/Run ----------------------------------------------------------------------------------------------------------------

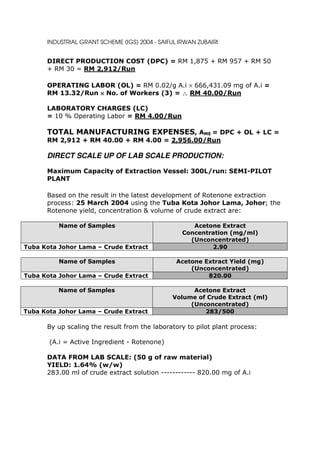

- 2. INDUSTRIAL GRANT SCHEME (IGS) 2004 - SAIFUL IRWAN ZUBAIRI DIRECT PRODUCTION COST (DPC) = RM 1,875 + RM 957 + RM 50 + RM 30 = RM 2,912/Run OPERATING LABOR (OL) = RM 0.02/g A.i ├Ч 666,431.09 mg of A.i = RM 13.32/Run ├Ч No. of Workers (3) = тИ┤ RM 40.00/Run LABORATORY CHARGES (LC) = 10 % Operating Labor = RM 4.00/Run TOTAL MANUFACTURING EXPENSES, AME = DPC + OL + LC = RM 2,912 + RM 40.00 + RM 4.00 = 2,956.00/Run DIRECT SCALE UP OF LAB SCALE PRODUCTION: Maximum Capacity of Extraction Vessel: 300L/run: SEMI-PILOT PLANT Based on the result in the latest development of Rotenone extraction process: 25 March 2004 using the Tuba Kota Johor Lama, Johor; the Rotenone yield, concentration & volume of crude extract are: Name of Samples Acetone Extract Concentration (mg/ml) (Unconcentrated) Tuba Kota Johor Lama тАУ Crude Extract 2.90 Name of Samples Acetone Extract Yield (mg) (Unconcentrated) Tuba Kota Johor Lama тАУ Crude Extract 820.00 Name of Samples Acetone Extract Volume of Crude Extract (ml) (Unconcentrated) Tuba Kota Johor Lama тАУ Crude Extract 283/500 By up scaling the result from the laboratory to pilot plant process: (A.i = Active Ingredient - Rotenone) DATA FROM LAB SCALE: (50 g of raw material) YIELD: 1.64% (w/w) 283.00 ml of crude extract solution ------------ 820.00 mg of A.i

- 3. INDUSTRIAL GRANT SCHEME (IGS) 2004 - SAIFUL IRWAN ZUBAIRI DATA FOR SEMI-PILOT PLANT SCALE: (25,000 g of raw material) YIELD: 2.66% (w/w) If, 230,000 ml (230 L) of crude extract solution ----------? mg of A.i 820.00 mg of A.i ______ ├Ч 230,000 ml of crude extract 283.00 ml of crude extract = 666,431.09 mg of A.i/Run contain in the 230 L of LIQUID CRUDE EXTRACT. ASSUMING THAT THE CONCENTRATION OF CONCENTRATED LIQUID CRUDE EXTRACT TO BE ACHIEVED IS 50 mg/ml AND THE ROTENONE CONTENT IS RETAINED (666,431.09 mg) BEFORE AND AFTER THE CONCENTRATION PROCESS. (ROTENONE LOSSES IS NEGLECTED тАУ ASSUMING TO BE 100% RECOVERY OF A.i) 2.90 mg/ml (Rotenone Conc.) ----------- 230 L of Liquid Crude Extract (UNCONCENTRTED)/Run 50 mg/ml (Rotenone Conc.) ------------ 13.33 L of Liquid Crude Extract (CONCENTRATED)/Run CALCULATION: 50 mg/ml ├Ч Y (VOLUME OF CONCENTRATED LIQ) = 666,431.09 mg of Rotenone So, Y (VOLUME OF CONCENTRATED LIQ) = 666,431.09 mg/50 mg ├Ч 1 ml тИ┤= 13.33 L/Run 13,328.62 ml (13.33 L) of Concentrated Liquid Crude Extract contains 666,431.09 mg of rotenone. IF, 1 ml of Concentrated Liquid Crude Extract тАУ 666,431.09 mg/13,328.62 ml ├Ч 1ml тИ┤1 ml of Concentrated Liq. Crude Extract --- 50 mg of rotenone 50 mg of rotenone ------------- 1 ml of Concentrated Liq. Crude Extract IF, 1g of A.i ------------ 1ml/50 mg ├Ч 1g = 20 ml So, Cost per unit weight of Rotenone = AME / 666,431.09 mg of A.i/Run RM 2,956.00/Run/666,431.09 mg of A.i/Run = RM 0.0044/mg A.i COST OF SEMI PRODUCT/RUN: тИ┤RM 4.40/g A.i/20 ml of Concentrated Liquid Crude Extract (1 g of A.i that contains in 20ml of Concentrated Liquid Crude Extract (SEMI PRODUCT) per run = RM 4.40

- 4. INDUSTRIAL GRANT SCHEME (IGS) 2004 - SAIFUL IRWAN ZUBAIRI PRODUCTION OF FORMULATED PRODUCT (3 % A.i) FROM 13.33 L OF CONCENTRATED LIQUID CRUDE EXTRACT PRODUCT (SEMI PRODUCT) ASSUMING THAT THE CONCENTRATION OF CONCENTRATED LIQUID CRUDE EXTRACT TO BE ACHIEVED IS 50 mg/ml AND THE ROTENONE CONTENT IS RETAINED (666,431.09 mg) BEFORE AND AFTER THE CONCENTRATION PROCESS. (ROTENONE LOSSES IS NEGLECTED тАУ ASSUMING TO BE 100% RECOVERY OF A.i) 2.90 mg/ml (Rotenone Conc.) ----------- 230 L of Liquid Crude Extract (UNCONCENTRTED)/Run 50 mg/ml (Rotenone Conc.) ------------ 13.33 L of Liquid Crude Extract (CONCENTRATED)/Run CALCULATION: 50 mg/ml ├Ч Y (VOLUME OF CONCENTRATED LIQ) = 666,431.09 mg of Rotenone So, Y (VOLUME OF CONCENTRATED LIQ) = 666,431.09 mg/50 mg ├Ч 1 ml тИ┤= 13.33 L/Run 13,328.62 ml (13.33 L) of Concentrated Liquid Crude Extract contains 666,431.09 mg of rotenone. IF, 1 ml of Concentrated Liquid Crude Extract тАУ 666,431.09 mg/13,328.62 ml ├Ч 1ml 1 ml of Concentrated Liq. Crude Extract --- 50 mg of Rotenone Production ratio of 1000 ml formulated product: ASSUMING 3 % A.i (w/v) 1. 3 % Active Ingredient (Rotenone) : 600 ml 0.03 ├Ч 1000 ml = 30 g A.i needed. IF, 0.05 g (50 mg) -- 1 ml of Concentrated Liq. Crude Extract So, 30 g A.i needed --- 1 ml/0.05 g ├Ч 30 g = 600 ml 600 ml of Concentrated Liquid Crude Extract is needed for obtaining the 30 g A.i (Rotenone) 2. Surfactant : 80 ml 3. Water : 320 ml

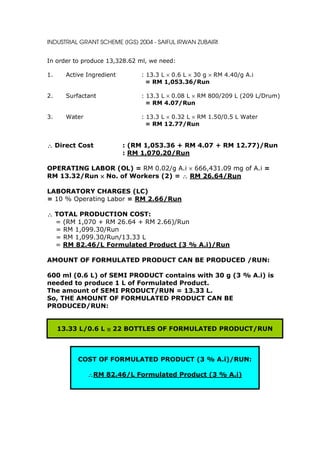

- 5. INDUSTRIAL GRANT SCHEME (IGS) 2004 - SAIFUL IRWAN ZUBAIRI In order to produce 13,328.62 ml, we need: 1. Active Ingredient : 13.3 L ├Ч 0.6 L ├Ч 30 g ├Ч RM 4.40/g A.i = RM 1,053.36/Run 2. Surfactant : 13.3 L ├Ч 0.08 L ├Ч RM 800/209 L (209 L/Drum) = RM 4.07/Run 3. Water : 13.3 L ├Ч 0.32 L ├Ч RM 1.50/0.5 L Water = RM 12.77/Run тИ┤ Direct Cost : (RM 1,053.36 + RM 4.07 + RM 12.77)/Run : RM 1,070.20/Run OPERATING LABOR (OL) = RM 0.02/g A.i ├Ч 666,431.09 mg of A.i = RM 13.32/Run ├Ч No. of Workers (2) = тИ┤ RM 26.64/Run LABORATORY CHARGES (LC) = 10 % Operating Labor = RM 2.66/Run тИ┤ TOTAL PRODUCTION COST: = (RM 1,070 + RM 26.64 + RM 2.66)/Run = RM 1,099.30/Run = RM 1,099.30/Run/13.33 L = RM 82.46/L Formulated Product (3 % A.i)/Run AMOUNT OF FORMULATED PRODUCT CAN BE PRODUCED /RUN: 600 ml (0.6 L) of SEMI PRODUCT contains with 30 g (3 % A.i) is needed to produce 1 L of Formulated Product. The amount of SEMI PRODUCT/RUN = 13.33 L. So, THE AMOUNT OF FORMULATED PRODUCT CAN BE PRODUCED/RUN: 13.33 L/0.6 L тЙЕ 22 BOTTLES OF FORMULATED PRODUCT/RUN COST OF FORMULATED PRODUCT (3 % A.i)/RUN: тИ┤RM 82.46/L Formulated Product (3 % A.i)