Project Charter GTL_Sewing DHU_ 24_ August 2016

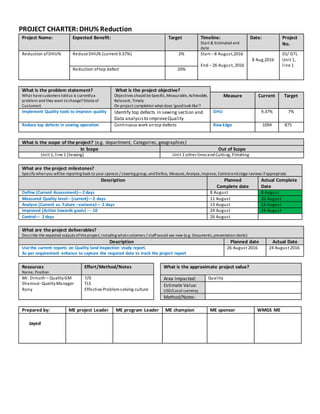

- 1. PROJECT CHARTER:DHU% Reduction Project Name: Expected Benefit: Target Timeline: Start & Estimated end date Date: Project No. Reduction ofDHU% Reduce DHU% (current 9.37%) 2% Start – 8 August,2016 End – 26 August, 2016 8 Aug,2016 01/ GTL Unit 1, line 1 Reduction oftop defect 20% What is the problem statement? What havecustomers toldus is currentlya problem and they want tochange? (Voiceof Customer) What is the project objective? Objectives should beSpecific,Measurable, Achievable, Relevant, Timely On project completion what does ‘goodlook like’? Measure Current Target Implement Quality tools to improve quality Identify top defects in sewing section and Data analysisto improveQuality DHU 9.37% 7% Reduce top defects in sewing operation Continuous work ontop defects Raw Edge 1094 875 What is the scope of the project? (e.g. department, Categories, geographies) In Scope Out of Scope Unit 1, line 1 (Sewing) Unit 1 other linesand Cutting, Finishing What are the project milestones? Specify whenyou willbe reporting back to your sponsor / steering group, andDefine, Measure,Analyse,Improve, Controlendstage reviews ifappropriate Description Planned Complete date Actual Complete Date Define (Current Assessment)—2 days 8 August 8 August Measured Quality level-- (current)—2 days 11 August 10 August Analyse (Current vs. Future –variance)— 2 days 13 August 13 August Improved (Action towards goals) --- 10 24 August 24 August Control— 2 days 26 August What are the project deliverables? Describe the expected outputs oftheproject,including whatcustomers / staffwould see new (e.g. Documents, presentation decks) Description Planned date Actual Date Use the current reports on Quality land Inspection study report. As per requirement enhance to capture the required data to track the project report 26 August 2016 24 August 2016 Resources Name, Position Effort/Method/Notes What is the approximate project value? Mr. Dimuth – QualityGM Shamsul- QualityManager Rony 7/0 TLS Effective Problemsolving culture Area Impacted: Quality Estimate Value: USD/Local currency Method/Notes: Prepared by: ME project Leader ME program Leader ME champion ME sponsor WMGS ME Jayed

- 2. Improvement - Action Points 1 Identify Top 5 defect in Sewing & FinishingSection- Completed 2 Daily Top 5 Defect Identification and Documentation - Completed 3 Select the Line with Highest DHU% & Identify top 5 process- Completed 4 Root CauseAnalysis & Progress check- Completed 5 Train & Motivate operator for 100% Inspection before passing(Startwith top defect operators) - Completed 6 Train Line Controller on TLS & 7/0 (selected Line) - Completed 7 Hourly check & Update TLS & 7/0 report – Completed 8 Start Needle & Thread tension check (twice a Day) top defect process- Not Properly done 9 Feasibility & accuracy of all Quality Data- Completed 10 Monitor Clock-wiseCheck in Sewing & FinishingQ.I and Set Standard time- Completed for Sewing 11 Maintain LineDiscipline& Proper M/C Cleaningfor Quality issue- Not maintained 12 Replace Dull Needle and Knife from top 5 defected process- Completed 13 Remove All Sharp edge, Rusty and spotsource from sewing Table- Completed 14 Change or Improve Foldingsystemfor raw edge defect (top 5 process) - Completed 15 Instructoperator for proper margin and trimming process –Completed 16 Instruction operator proper Feeding and Handlingof garments- Completed 17 Empowerment of Operator to Immediately Send back defected garments to previous operator & followup- Not Completed 18 Proper Ironingsystem & pattern Check- Completed 19 Instruction for Check for Miss Match parts before sewing(operator) & Line-feeding (Line supervisor) & followUp- Complete