Qualimatest - Automatic quality control system for cutting industry

- 1. Unique solutions for quality control QUALIMATEST SA Automatic quality control for the cutting industry QUALIMATEST SA |Chemin du Pont du Centenaire 109 1228 Plan-les-Ouates (Gen├©ve) | Suisse Tel : +41 22 884 00 30 | Fax : +41 22 884 00 40| info@qmt.ch

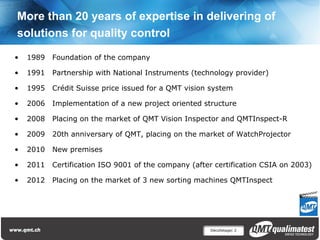

- 2. More than 20 years of expertise in delivering of solutions for quality control ŌĆó 1989 Foundation of the company ŌĆó 1991 Partnership with National Instruments (technology provider) ŌĆó 1995 Cr├®dit Suisse price issued for a QMT vision system ŌĆó 2006 Implementation of a new project oriented structure ŌĆó 2008 Placing on the market of QMT Vision Inspector and QMTInspect-R ŌĆó 2009 20th anniversary of QMT, placing on the market of WatchProjector ŌĆó 2010 New premises ŌĆó 2011 Certification ISO 9001 of the company (after certification CSIA on 2003) ŌĆó 2012 Placing on the market of 3 new sorting machines QMTInspect D├®colletage| 2

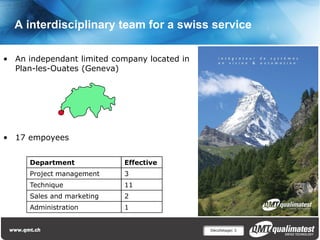

- 3. A interdisciplinary team for a swiss service ŌĆó An independant limited company located in Plan-les-Ouates (Geneva) ŌĆó 17 empoyees Department Effective Project management 3 Technique 11 Sales and marketing 2 Administration 1 D├®colletage| 3

- 4. The reliability of our products and service are the central values of Qualimatest D├®colletage| 4

- 5. A very high level of service for the realization of vision and automation solutions D├®colletage| 5

- 6. An organization for maintenance management and sustainability ŌĆó An organization to ensure optinum equipment operation throughout their life ŌĆó Basic benefits o Assistance and support with guaranteed delivery times o Telemaintenance ŌĆó A proposal with choice options for the customer o Updating of the software o Preventive maintenance o Spare parts o Management of the sustainability of the equipment o Others according to customer requests D├®colletage| 6

- 7. A large customer panel ŌĆó 4 main markets : Watch (50%), Railway (15%), Automotive (25%), Medical (10%) ŌĆó Swiss and international customers o Watch : Audemars Piguet, Breitling, Patek Philippe, Ulysse Nardin, Swatch Group, ŌĆ” o Rail : CFF, Speno International o Automotive :Baud Industries, Continental, DuPont, Sonceboz, ŌĆ” o Medical : Allergan, Becton Dickinson, Johnson & Johnson, Medtronic, ŌĆ” ŌĆó More than 300 installed and maintained systems worldwide D├®colletage| 7

- 8. The strengths of Qualimatest solutions for automatic quality control ŌĆó Improve the repeatability of the control ŌĆó Lower costs of visual control (mean tens of kŌé¼ per year with an automatic sorting machine) ŌĆó Minimize the costs of non-quality by automatic 100% control ŌĆó Collect statistical data to drive the production and continuous improvement D├®colletage| 8

- 9. Qualimatest offers a high level of service ŌĆó An ISO 9001 certified organization ŌĆó A draft process adapted to the industrial world to ensure achievement of customerŌĆÖs objectives and deadlines ŌĆó A team of experts in vision, computer science, mechanical and automation ŌĆó Long experience in the automotive markets and micromechanics ŌĆó An organization for the maintenance management of delivered equipments D├®colletage| 9

- 10. Control systems for vision based on a powerful and efficient swiss made platform QMTView ŌĆó A reliable base of development with a userŌĆÖs interface and multilanguage ŌĆó Security, events logbook, etc ŌĆ” QMT Vision Inspector ŌĆó Hardware platform QVIHardware complete and compatible, proposed by market leaders to ensure perennity and maintenance ŌĆó Treatment engine for images QVIEngine configurable to guarantee maintenance and evolution ŌĆó Standard communication QVICom by I/O, TCP-IP and RS232 ŌĆó A multi language utilization supervisor existing in three versions QVIBase, QVIPro et QVIPro-MS to better fit with utilization needs ŌĆó A complete range of services D├®colletage| 10

- 11. A large expertise in esthetical quality control ŌĆó Technology being developed in collaboration with EPFL ŌĆó QMTSubFace technolgy is integrated in QMT Vision Inspector platform ŌĆó A reliable and automatic methodology for esthetical quality control that takes into account the subjective and human analyses to the definition of acceptance limits ŌĆó Integrated in WatchProjector and QMTInspect D├®colletage| 11

- 12. WatchProjector : Optical equipment for automatic measure and control without contact ŌĆó A measure time of less than one second with an accuracy of less than one micron ŌĆó Automatic recognition of components does not require precise positioning ŌĆó An DXF superposition with automatic referencing on the part ŌĆó A software easy to use by operators and efficient to create programs by a technician ŌĆó A library of measurement functions ŌĆó Cutting industry applications o Accurate without appreciation by the operator of components or finished products o Production driving D├®colletage| 12

- 13. QMTInspect : Sorting machines for guaranteed 100% control D├®colletage| 13

- 14. QMTInspect-R : Control and sorting machine (glass plate) for guaranteed 100% conformity The specifications of the QMTInspect-R ŌĆó Automatic feeding of parts ŌĆó Several measurement stations modular o Vision, laser, air pad, ŌĆ” o Dimensional measurements with a repeatability down to 1 micron o Characterization of surfaces (scratches, stains, ŌĆ”) o Presence/ absence ŌĆó Automatic multiple ejection of pieces according to measurement results ŌĆó Speed: up to 10 pieces per second D├®colletage| 14

- 15. QMTInspect-RM : Control and sorting machine (glass plate) for microtechnical pieces The specifications of the QMTInspect- RM ŌĆó Control and sorting of small components, typically from watches with high accuracy ŌĆó Automatic feeding of pieces by vibrating bowl or Asyfeed Pocket ŌĆó 1 or 2 stations with 1 ou 2 cameras o Any type of measurements with a maximum accuracy of 1 micron o No chips, stains, scratches, chocks ŌĆó Automatic multiple ejection of the pieces according to the measurement results ŌĆó Speed: up to 4 pieces per second D├®colletage| 15

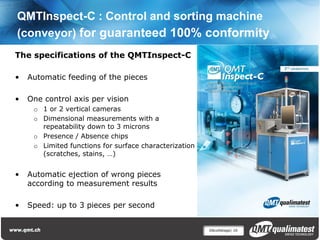

- 16. QMTInspect-C : Control and sorting machine (conveyor) for guaranteed 100% conformity The specifications of the QMTInspect-C ŌĆó Automatic feeding of the pieces ŌĆó One control axis per vision o 1 or 2 vertical cameras o Dimensional measurements with a repeatability down to 3 microns o Presence / Absence chips o Limited functions for surface characterization (scratches, stains, ŌĆ”) ŌĆó Automatic ejection of wrong pieces according to measurement results ŌĆó Speed: up to 3 pieces per second D├®colletage| 16

- 17. QMTInspect-PL : Control and sorting machine (linear and housing) for microtechnical pieces The specifications of the QMTInspect- PL ŌĆó Control and sorting of small components, typically from watches, especially cylindrical (cutting industry) with very high accuracy ŌĆó Automatic feeding of the pieces by vibrating bowl or Asyfeed Pocket ŌĆó One vision station with 1 or 2 cameras o Any type of measurement with an accuracy of down to 0.7 microns o No chips, stains, scratches, chocks ŌĆó Automatic multiple ejection of the pieces according to measurement results avec options de mise en plateau ŌĆó Speed: up to 1 piece per second D├®colletage| 17

- 18. Specific developments to perfectly answer your needs

- 19. Equipment for automatic reading of engraved numbers on watch components D├®colletage| 19

- 20. Equipment for final quality control on medical device in cleanroom D├®colletage| 20

- 21. Welding station assisted by vision for the medical industry D├®colletage| 21

- 22. Quality Control of Pens for insuline injection D├®colletage| 22

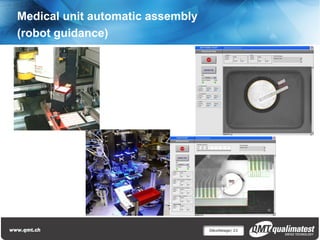

- 23. Medical unit automatic assembly (robot guidance) D├®colletage| 23

- 24. Railway measuring system D├®colletage| 24

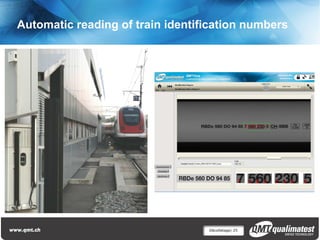

- 25. Automatic reading of train identification numbers D├®colletage| 25

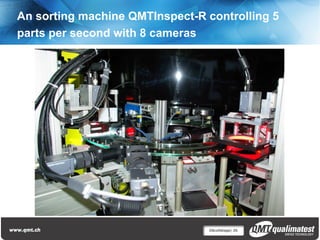

- 26. An sorting machine QMTInspect-R controlling 5 parts per second with 8 cameras D├®colletage| 26

- 27. Welding control D├®colletage| 27

- 28. Bars control for cutting tools manufactoring D├®colletage| 28

- 29. Current sensors quality control D├®colletage| 29

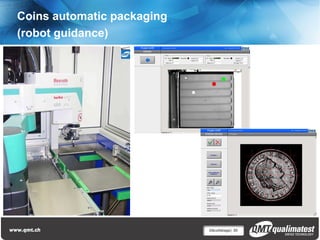

- 30. Coins automatic packaging (robot guidance) D├®colletage| 30

- 31. Stay connected with Qualimatest or contact us Stay connected with Qualimatest www.qmt.ch www.linkedin.com/company/qualimatest-sa www.facebook.com/pages/Qualimatest/107384899337851?fref=ts www.youtube.com/user/qmtmeissner ( indique lŌĆÖexistence dŌĆÖun film) fr.slideshare.net/QMTMeissner Contact us Chemin du Pont-du-Centenaire 109, 1228 Plan-les-Ouates (Gen├©ve) T├®l. : + 41 - 22 884 00 30 Fax : + 41 - 22 884 00 40 Email : info@qmt.ch D├®colletage| 31