RECOMBINED SWEETENED MILK

- 1. WELCOME

- 2. INTRODUCTION: Recombination process is applied for production of most dairy products and it has helped in creating new foods and formulations. Recombination is the process of recombining milk fat and milk solids-not fat (SNF) in one or more of their various forms with or without water. This recombination must be made so as to re- establish the product's specified fat-to-SNF ratio and solids-to-water ratio. The recombined process was first used widely during World War II and then onward spreaded worldwide. The main advantages derived are: KARNATAKA VETERINARY ANIMAL AND FISHERIES SCIENCES UNIVERSITY BIDAR DAIRY SCIENCE COLLEGE KALABURAGI

- 3. TOPIC: Recombined Sweetened Condensed Milk Presented To: Mr.Shankarlingayya Asst.Professor of Dairy technology Dairy science college Kalaburagi Presented By: Chethan N DGK1303 2nd year 2ndsem

- 4. INTRODUCTION: ïž Recombination process is applied for production of most dairy products and it has helped in creating new foods and formulations. ïž Recombination is the process of recombining milk fat and milk solids-not fat (SNF) in one or more of their various forms with or without water. ïž This recombination must be made so as to re-establish the product's specified fat-to-SNF ratio and solids-to-water ratio. ïž The recombined process was first used widely during World War II and then onward spreaded worldwide.

- 5. The main advantages derived are: 1) It gives better opportunities for transfer of raw material from a surplus area via industrial manufacturing to fulfill demand in deficiency areas for local range of milk and milk products. (2) It supplements and supports local milk and other products such as vegetable oils and sugars. (3) It generates possible employment for local population at dairy as well as with related activities, and (4) It creates goodwill and interest with authorities.

- 6. Add Skim milk powder to the water [stirr at 50â°C approximately 20 minutes] Add the melted fat and other dry ingredients Deaerate Preheat to 60° C Homogenization: 40 kp/cm2. Pasteurization: 90° C/1 min. Flash cool to 30° C Seed with lactose

- 7. Crystalization Filling PROCEDURE: * Add skim milk powder to the water, while stirring, at approx. 50° C. Stir for approx. 20 min. * Melt the fat. * Add the melted fat, PalsgaardÂŪ DairyEmulsifier 010, PalsgaardÂŪ RecMilk 100 and other dry ingredients to the water phase, while stirring. * Deaerate.

- 8. * Preheat to 60° C. * Homogenization: 40 kp/cm2. * Pasteurization: 90° C/1 min. * Flash cool to 30° C, removing 4-6% water. * Seed with lactose, 0.02%. * Crystalization for 1-2 hours. * Filling

- 9. RSCM Processing: Mixing : ï Dispersion is effected using a high speed blade, a powder funnel and centrifugal pump, a powder/liquid blender or number of other devices designed for the purpose. Care should be taken to minimize air incorporation or a deaerator can be used. ï Liquid fat (55-60%) may be added before, after or with powder to minimize foaming. Uniform dispersion of fat to maintain protein/fat ratio at homogenization is required otherwise fat separation results. ï The SMP is dissolved in water heated to 40-50°C first to give solids concentration of 44%.

- 10. ï After hydration time of about 15 min during which the dispersed powder completes its dissolution, the sugar can be added and dissolved (agitation stopped to minimize air incorporation and to save power). ï During sugar addition, mix is heated to maintain temperature at 40-50°C. Then previously melted fat (50 °C) is added while mixing and the mix is further heated to 50- 60°C to facilitate filtration. ï When full cream powder is used, highest possible level of TS (52%) is used at mixing stage to achieve maximum economy.

- 11. Filtration: Filtration is carried out on duplex-type filters using a range of filter materials to remove extraneous material from milk prior to homogenization. Preheating: Preheating to homogenization temperature, 50-60°C is done. Higher temperature adversely affects heat stability of recombined evaporated milk. Homogenization: ïž From several systems, high pressure unit using shear type valve is commonly used for recombined EM preparation. Usual pressures are in range of 140 â 175 kg/cm2 for first stage, and 35 kg/cm2 on second stage.

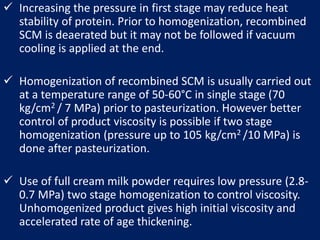

- 12. ïž Increasing the pressure in first stage may reduce heat stability of protein. Prior to homogenization, recombined SCM is deaerated but it may not be followed if vacuum cooling is applied at the end. ïž Homogenization of recombined SCM is usually carried out at a temperature range of 50-60°C in single stage (70 kg/cm2 / 7 MPa) prior to pasteurization. However better control of product viscosity is possible if two stage homogenization (pressure up to 105 kg/cm2 /10 MPa) is done after pasteurization. ïž Use of full cream milk powder requires low pressure (2.8- 0.7 MPa) two stage homogenization to control viscosity. Unhomogenized product gives high initial viscosity and accelerated rate of age thickening.

- 13. Pasteurization and Cooling: ï§ Recombined EM may be heated to homogenization temperature or pasteurized to extend its storage life and cooled to < 5°C. Pasteurization conditions used for recombined SCM vary in range of 80-90°C for 30 sec to 2 min. ï§ Use of 91°C for 30 sec gives adequate safety to product from yeasts without adverse effect on color or flavour. However, holding the product at higher temperature for longer period gives discoluration due to Maillard reaction. ï§ The recombined SCM must be handled aseptically here on. Cooling in plate heat exchanger up to 50°C and then by vacuum cooling to 30°C is carried out.

- 14. Lactose Seeding : In recombined SCM, formation of greatest number of small crystals (<10 Âĩ) is required to control large crystal formation giving sandy mouth feel. Addition of very finely ground seed lactose powder (300 mesh, ~ 1-10 Âĩ size) with high microbiological standards is done at a rate of about 0.05 % either as powder or as slurry. Alternatively, skim milk powder or sweetened condensed milk of previous batch can be used as seed material. After crystallization, further cooling under vacuum leads to about 10 % moisture evaporation and hence suitable allowances are made in original mix.

- 15. Storage, Stabilization and Standardization: ïķ The viscosity of EM is determined and solids level is adjusted to required specification. ïķ Addition of phosphates, citrates and sometimes calcium is required to stabilize proteins against heat effects during sterilization but their use should be kept to a minimum to avoid adverse effect on flavour of the product. ïķ The level of stabilizer is determined by taking trials and then whole batch can be standardized for canning.

- 16. Canning and Sterilization : The essentials in canning recombined EM are clean, well made cans, minimum foam, appropriate head space, correct weight and efficient closure. Any type of sterilization method employed should be efficiently performed and rapid cooling should follow to avoid any defect. Careful packaging to avoid any contamination from external sources is required for recombined SCM along with minimum headspace while filling to prevent growth of any surviving moulds.

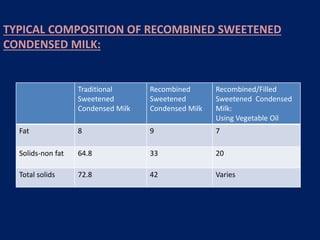

- 17. TYPICAL COMPOSITION OF RECOMBINED SWEETENED CONDENSED MILK: Traditional Sweetened Condensed Milk Recombined Sweetened Condensed Milk Recombined/Filled Sweetened Condensed Milk: Using Vegetable Oil Fat 8 9 7 Solids-non fat 64.8 33 20 Total solids 72.8 42 Varies

![Add Skim milk powder to the water

[stirr at 50â°C approximately 20 minutes]

Add the melted fat and other dry ingredients

Deaerate

Preheat to 60° C

Homogenization: 40 kp/cm2.

Pasteurization: 90° C/1 min.

Flash cool to 30° C

Seed with lactose](https://image.slidesharecdn.com/cbhaghatrscm-181210174114/85/RECOMBINED-SWEETENED-MILK-6-320.jpg)