Respiratory-Protection basics and clarification

- 2. Regulatory Requirements ’é© Covers all required and voluntary use of respiratory protection in general industry ’é© Requires a written program ’é© Requires employee training, medical evaluation, and fit-testing 2

- 3. Types of Respiratory Protection ’é© Atmosphere supplying ’éż Self-contained breathing apparatus (SCBA) ’éż Airline respirators ’é© Air purifying ’éż Gas and vapor ’éż Particulate ’éż Combination 3

- 4. Types of Face Pieces ’é© Mouthpiece ’é© Single use/disposable ’é© Quarter mask ’é© Half mask ’é© Full face ’é© Helmet 4

- 5. Effective Use of Respirators ’é© During installation of engineering controls ’é© During maintenance operations ’é© During process turnarounds ’é© For non-routine tasks ’é© For emergency response ’é© At hazardous waste site operations ’é© When other controls are inadequate ’é© When other controls are not feasible 5

- 6. Employee Effectiveness The use of respiratory protection limits the effectiveness of the employee by 33.33 percent. 6

- 7. Respirator Selection Criteria ’é© Physical state of the contaminant ’é© Contaminant concentration ’é© Oxygen deficiency ’é© Warning properties of contaminant ’é© Immediate Danger to Life Health atmospheres ’é© Can contaminant be ad/absorbed by a media? ’é© Can contaminant be ad/absorbed by the skin? ’é© Is the contaminant irritating to the eyes? 7

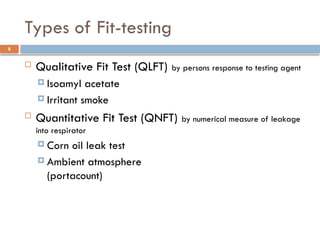

- 8. Types of Fit-testing ’é© Qualitative Fit Test (QLFT) by persons response to testing agent ’éż Isoamyl acetate ’éż Irritant smoke ’é© Quantitative Fit Test (QNFT) by numerical measure of leakage into respirator ’éż Corn oil leak test ’éż Ambient atmosphere (portacount) 8

- 9. Elements of a Respiratory Protection Program ’é© Written operating procedures ’é© Proper selection ’é© Training and fitting ’é© Cleaning and disinfecting ’é© Storage ’é© Inspection and maintenance ’é© Work area surveillance 9

- 10. Respiratory Program (cont.) ’é© Inspection and evaluation to determine effectiveness ’é© Medical examinations ’é© Approved respirators 10

- 11. Written Program Requirements ’é© Must be site-specific ’é© Must have a program administrator ’é© Must be developed when respirator use is required 11

- 12. When Respirators Are Not Required ’é© Can use employee respirator if it does not create a hazard ’é© Voluntary users of respirators must be given Appendix D ’é© Appendix D = employee information when respirators are not required ’é© Employers must implement a program for non-required users 12

- 13. Respirators Not Required (cont.) ’é© If dust masks only are used and not required, no written program is required ’é© Appendix D of the standard must be provided to users 13

- 14. General Requirements ’é© Use of NIOSH-approved respirators only ’é© Evaluation of hazards ’é© Availability of multiple respirator types 14

- 15. Respirators for Non-IDLH Use ’é© If cartridges have no ŌĆ£end of service life indicatorŌĆØ a change schedule must be used ’é© Added table for oxygen-deficient atmospheres based on altitude 15

- 16. Medical Evaluation ’é© Use of medical questionnaire (Appendix C) ’é© Follow-up medical exam for any positive response to questionnaire ’é© All medical evaluations must be made confidentially ’é© Employees must be allowed to discuss the questionnaire with the physician 16

- 17. Medical Evaluation (cont.) ’é© Physicians must be told conditions of respirator use ’é© Employers must provide a PAPR if employees cannot use a negative pressure APR ’é© Follow-up evaluations must be conducted if conditions of use or user health change 17

- 18. Fit-Testing ’é© Respirators will not protect you if they donŌĆÖt fit properly! ’é© Required for negative or positive pressure tight-fitting face pieces ’é© Must be conducted prior to use ’é© Must be conducted at least annually ’é© Must be retested if respirator fit or wearer changes 18

Editor's Notes

- #1: I. SpeakerŌĆÖs Notes: One of the most common means of protecting employee health is respiratory protection. However, there are several legal requirements that must be followed to properly use respiratory protection. This program focuses on the fundamental issues of respiratory protection as well as the basic regulatory requirements.

- #2: I. SpeakerŌĆÖs Notes: Respiratory protection is included with the other standards on personal protective equipment. If you use respiratory protection, it is important that all regulatory elements be in place. This program will include the recent revisions to the respiratory protection program.

- #3: I. Background for the Trainer: Show examples of the available types of respirators to the class. II. SpeakerŌĆÖs Notes: The most common type of respirator in use today is the air-purifying variety. It is important to remember that these respirators do not supply oxygen, they simply filter the air that we breathe. Another type of respirator is an atmosphere supplying respirator. It is commonly used by emergency responders and spill cleanup personnel.

- #4: I. SpeakerŌĆÖs Notes: Of these types of face pieces, you are not likely to see the mouthpiece or quarter mask much any more. More commonly you will find the single-use disposable, half mask, or full face. Both air-purifying and atmosphere-supplying respirators use both half mask and full face configurations.

- #5: I. SpeakerŌĆÖs Notes: Respirators should never be your first line of defense because they can be difficult to use. However, this list of situations provides a foundation for the effective use of respiratory protection. Keep in mind that nonroutine tasks are those typically performed by the maintenance or other service organization. Each nonroutine task will vary, and it is difficult to implement engineering controls for that reason; therefore, respirators are used extensively in maintenance operations.

- #6: I. SpeakerŌĆÖs Notes: No employee likes to wear a respirator. A respirator offers protection, but as this slide demonstrates, it certainly doesnŌĆÖt enhance your ability to get the job done. ItŌĆÖs important that youŌĆÖre comfortable with the respirator you wear. If youŌĆÖre not, notify your supervisor. A better fit can usually be found.

- #7: I. Speaker Notes: All of these criteria should be taken into account when choosing a respirator. Is it a liquid, gas, or solid? How many ppm or mg/m3, etc., are in the environment? Is there enough oxygen to sustain life? How easy is it to detect the contaminant with the human senses (e.g., smell)? Is it likely that we may encounter an Immediately Dangerous to Life and Health (IDLH) atmosphere? Do we have the proper filter media for the given contaminant (e.g., HEPA cartridge for dusts)? Is there a hazard if the contaminant contacts the skin? Can it harm our eyes if contact is made?

- #8: I. SpeakerŌĆÖs Notes: If we use respirators, we must ensure that they are of a size and type that adequately fit the wearer. Qualitative fit-testing is very subjective and relies on the wearer to identify whether or not they smell or taste the challenge agent. Quantitative fit-testing provides a number called a fit factor, which can identify the quality of the fit and document compliance with the OSHA standards. This method uses dioctyl phthalate, corn oil, or ambient atmospheric particles.

- #9: I. SpeakerŌĆÖs Notes: As with many OSHA standards, 1910.134 says that if any employees are required to wear respirators, the company must have an adequate written program. The elements in this slide are those elements that must be covered by the overall program. It is also important that respirator users and their supervisors be effectively trained in these requirements.

- #10: I. SpeakerŌĆÖs Notes: These elements are also required to be in the companyŌĆÖs respiratory protection program.

- #11: I. SpeakerŌĆÖs Notes: Companies not only have to have a written program, but it must be site-specific. No boilerplate programs will be accepted by OSHA. The program must state how our company will meet the requirements. Someone should also be designated as the responsible person, typically the safety and health professional.

- #12: I. SpeakerŌĆÖs Notes: You can now use your own respiratory protection as long as it does not create an additional hazard. Basically, that means that employers still have the fundamental responsibility to ensure that the respirator in use is appropriate for the job. If your respirator use is voluntary, make sure you are given Appendix DŌĆöEmployee Information When Respirators Are Not Required. If they are not required, but an employer still allows their use, the employer must implement a program to ensure respirators are used effectively.

- #13: I. SpeakerŌĆÖs Notes: The major exception to the voluntary use rule is dust masks or single-use disposables. If only dust masks are used on a voluntary basis, no written program is required. Employers must make sure that the voluntary users of dust masks are still provided with Appendix D of the standard.

- #14: I. SpeakerŌĆÖs Notes: The new standard requires that all respirators be NIOSH approved. The old standard called for NIOSH/OSHA approval, but now, only NIOSH approval is required. The language is now in the standard that requires employers to provide a very specific evaluation of the hazards to ensure that the proper respirators are used. OSHA has always suggested it, but now it is in black-and-whiteŌĆöa company must have more than one type and size of respirator available due to varying characteristics in the user that affect fit, as well as the comfort of the respirator itself.

- #15: I. SpeakerŌĆÖs Notes: If cartridges have no end of service life indicator, employers must come up with their own schedule for cartridge change out. It is recommended that employers obtain information from various manufacturers to assist in developing the change schedule. The oxygen deficiency table will be of value in areas of high altitude; otherwise, differences are negligible.

- #16: I. SpeakerŌĆÖs Notes: Employers must use the lengthy medical questionnaire found in Appendix C of the OSHA regulation. This questionnaire is sensitive and has to be shared only with the licensed health care professional. If any employee responds positively to any of the questions, the health care professional must provide a medical exam for follow-up. Employers must also allow the employees an opportunity to discuss the questionnaire with the attending health care professional.

- #17: I. SpeakerŌĆÖs Notes: Your employer will also educate the medical professionals on the types of respirators in use as well as their operation and limitations. It is extremely important to give the medical professionals an opportunity to examine the respirators first hand. Things such as the additional 35 to 40 pounds of weight when using an SCBA are definite factors in the medical approval process. Powered air purifying respirators must be made available if you are required to wear a respirator and cannot use a negative pressure air-purifying respirator (assuming the negative pressure device provides adequate protection).

- #18: I. SpeakerŌĆÖs Notes: One significant change in the regulation is that fit-testing is now required for all negative and positive pressure devices. Prior standards did not require fit-testing for positive pressure devices. These tests are also now required annually. All respirators need to be fit-tested to be sure you are receiving adequate protection. If a respirator doesnŌĆÖt fit properly, it wonŌĆÖt protect you!