C - Retread Procedures for Commercial Tires

- 1. Commercial Tire Retreading Robert C. McElroy, Ph.D. www.ForensicAccident.Com Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 1

- 2. Tire Definition Bubba Academic big & dirty flexible pressure vessel flat-on-bottom Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 2

- 3. Retread Training Program Dr. McElroy Attended ITRA Training Institute 40 Hour Commercial Tire Retreading Class Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 3

- 4. Retreading Is: ŌĆó Bonding a new tread to a worn tire casing Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 4

- 5. What is a Worn Casing ŌĆóis a properly It maintained tire that has worn out its useful tread life and been removed from service for retreading. Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 5

- 6. Vulcanizing or Curing ŌĆó Process of chaining macromolecules together. Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 6

- 7. Vulcanizing Involves ŌĆó Time ŌĆó Temperature ŌĆó Pressure Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 7

- 8. Tire Classification ŌĆó Passenger ŌĆó Truck Light ŌĆó Medium Truck ŌĆó Heavy Truck ŌĆó Off-Road ŌĆó Aircraft ŌĆó Agricultural ŌĆó Industrial / Mining ŌĆó Racing Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 8

- 9. Tire Retreading Involves ŌĆó Inspection ŌĆó Repairing ŌĆó Buffing / Skiving ŌĆó Cementing / Filling ŌĆó Tread Application ŌĆó Wicking / Enveloping ŌĆó Vulcanization ŌĆó Inspection Final Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 9

- 10. Mold Cure Retreading Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 10

- 11. Pre Cure Retreading Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 11

- 12. TodayŌĆÖProfessional Retreader s Must Know & Understand ŌĆó construction Tire ŌĆó sizes & what they Tire mean ŌĆó usage & application Tire ŌĆó maintenance Tire ŌĆó Tread design & functions ŌĆó Retread processing technology Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 12

- 13. Maintenance & Wheel Position Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 13

- 14. Tread Compounds Should Have: ŌĆó heat generation Low ŌĆó traction Good ŌĆó tear resistance High ŌĆó rolling resistance Low Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 14

- 15. Rolling Resistance Is Affected By: ŌĆó load Tire ŌĆó Inflation ŌĆó Tread compound ŌĆó construction Tire ŌĆó Tread depth ŌĆó Tread design Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 15

- 16. Road Factors ŌĆó Surface Characteristics ŌĆó Water depth ŌĆó Temperature Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 16

- 17. Vehicle Factors ŌĆó Speed ŌĆó Mode of operation ŌĆó Suspension ŌĆó Braking system ŌĆó Types of load ŌĆō liquid ŌĆō CG high Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 17

- 18. Heat History ŌĆó quantity of heat accumulated The over a period of time. Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 18

- 19. Tire Heat Exposure ŌĆó Original manufacturing temperatures. ŌĆó Original tread life operating temperatures. ŌĆó Retread process temperatures. Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 19

- 20. Typical Radial Truck Tire Operating on the Road 200o F 93o C Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 20

- 21. Typical Radial Truck Tire Original Tread Life 200,000 to 250,000 Miles 320,000 to 400,000 KM Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 21

- 22. Loads Heat buildup area Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 22

- 23. Tire Inflation Pressure ŌĆó / under inflation. Over ŌĆó Buffed too round / too flat. ŌĆó retread / narrow Wide retread. ŌĆó / narrow Wide processing rims or narrow road rims. Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 23

- 24. Low Air Pressure ŌĆó Increases running temperature. ŌĆó Reduces fuel economy. ŌĆó20% reduction in A inflation pressure causes a 16% reduction in tread life. Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 24

- 25. Effects On Tread Wear ŌĆó inflation by 10% Over reduces tread life 5- 8%. ŌĆó inflation by 20% Over reduces tread life 16%. ŌĆó Matching duals ŌĆó Torque, braking, stopping & cornering. Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 25

- 26. To Select Tires for Retreading ŌĆó Manufacturing defects ŌĆó Non-repairable damage ŌĆó Excessive age ŌĆó tire be retreaded Can again? Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 26

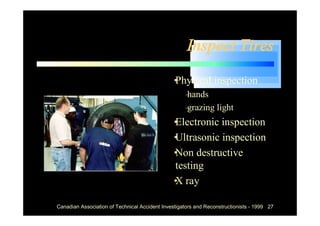

- 27. Inspect Tires ŌĆó Physical inspection ŌĆō hands ŌĆō grazing light ŌĆó Electronic inspection ŌĆó Ultrasonic inspection ŌĆó destructive Non testing ŌĆóray X Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 27

- 28. Electronic Inspection Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 28

- 29. Physical Inspection Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 29

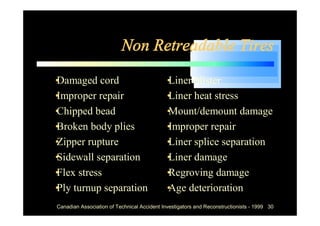

- 30. Non Retreadable Tires ŌĆó Damaged cord ŌĆó blister Liner ŌĆó Improper repair ŌĆó heat stress Liner ŌĆó Chipped bead ŌĆó Mount/demount damage ŌĆó Broken body plies ŌĆó Improper repair ŌĆó Zipper rupture ŌĆó splice separation Liner ŌĆó Sidewall separation ŌĆó damage Liner ŌĆó stress Flex ŌĆó Regroving damage ŌĆó turnup separation Ply ŌĆó deterioration Age Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 30

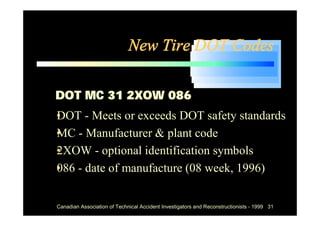

- 31. New Tire DOT Codes DOT MC 31 2XOW 086 ŌĆó - Meets or exceeds DOT safety standards DOT ŌĆó - Manufacturer & plant code MC ŌĆó 2XOW - optional identification symbols ŌĆó - date of manufacture (08 week, 1996) 086 Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 31

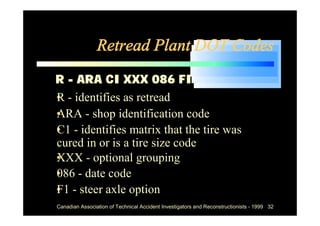

- 32. Retread Plant DOT Codes R - ARA CI XXX 086 FI ŌĆó identifies as retread R- ŌĆó - shop identification code ARA ŌĆó - identifies matrix that the tire was C1 cured in or is a tire size code ŌĆó - optional grouping XXX ŌĆó - date code 086 ŌĆó - steer axle option F1 Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 32

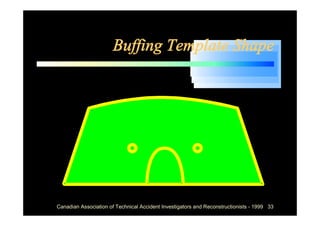

- 33. Buffing Template Shape Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 33

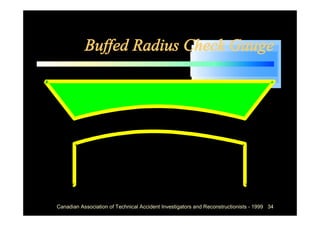

- 34. Buffed Radius Check Gauge Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 34

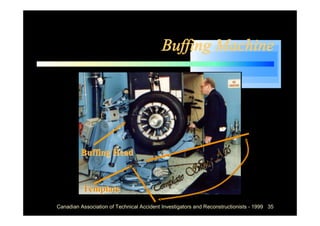

- 35. Buffing Machine Buffing Head Template Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 35

- 36. Apply Cement To: ŌĆó Protect buffed surface & exposed cords from oxidation. ŌĆó Improves adhesion by providing for more ŌĆ£intimate contactŌĆØ to buffed casing. Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 36

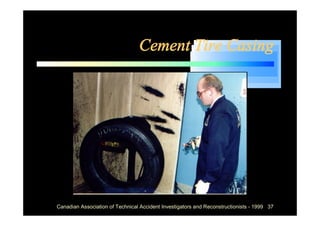

- 37. Cement Tire Casing Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 37

- 38. Cement = Rubber Solids Dissolved in Solvents ŌĆó Allow 15 minutes to dry after application. ŌĆó Install tread within 12 hours. ŌĆó Chemical ŌĆó vulcanizing Black ŌĆó Concentrated or brush ŌĆó Spray ŌĆó Extruder or hot tack Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 38

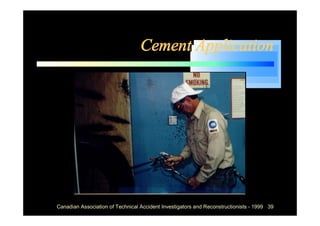

- 39. Cement Application Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 39

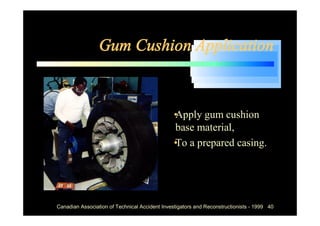

- 40. Gum Cushion Application ŌĆó Apply gum cushion base material, ŌĆó a prepared casing. To Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 40

- 41. Gum Cushion to Tire Contact Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 41

- 42. Trim Gum Cushion Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 42

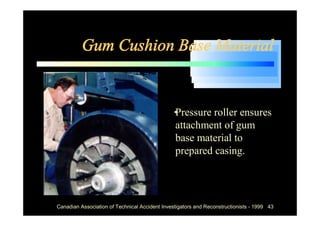

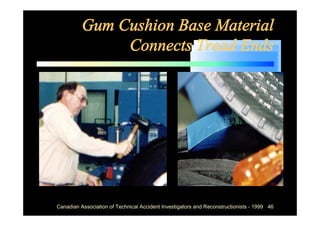

- 43. Gum Cushion Base Material ŌĆó Pressure roller ensures attachment of gum base material to prepared casing. Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 43

- 44. Precure Tread Installation ŌĆó Texturize tread end & cement. ŌĆó tread straight holding tightly. Feed ŌĆó cut point even or slightly longer. Mark ŌĆó straight & match tread design if possible. Cut ŌĆó cushion between tread ends. Place ŌĆó splice with least amount of hump. Butt ŌĆó rubber toward splice & from center out. Work ŌĆó Install DOT identification code. ŌĆó Apply poly. Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 44

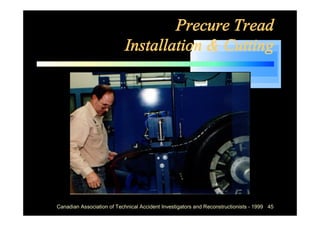

- 45. Precure Tread Installation & Cutting Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 45

- 46. Gum Cushion Base Material Connects Tread Ends Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 46

- 47. Poly Installation Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 47

- 48. DOT Identification Code Installation Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 48

- 49. Select Tire Envelope Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 49

- 50. Envelope on Expander Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 50

- 51. Envelope Expanded Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 51

- 52. Tire Insertion Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 52

- 53. Envelope Adjustment Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 53

- 54. Rim & Flange Installation Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 54

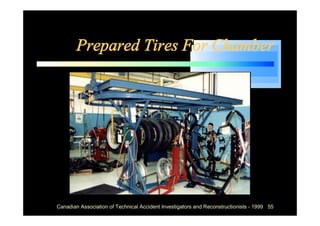

- 55. Prepared Tires For Chamber Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 55

- 56. Curing in Autoclave or Chamber Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 56

- 57. Track Installation Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 57

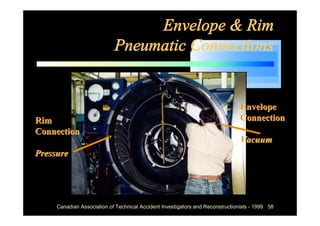

- 58. Envelope & Rim Pneumatic Connections Envelope Rim Connection Connection Vacuum Pressure Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 58

- 59. Seal & Lock Chamber Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 59

- 60. Set Time & Temperature Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 60

- 61. Post Vulcanization Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 61

- 62. Final Inspection Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 62

- 63. References Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 63

- 64. Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 64

- 65. Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 65

- 66. Dr. McElroy Examining Retreaded Tire The End Canadian Association of Technical Accident Investigators and Reconstructionists - 1999 66