Reznoclad Brochure final_2016

- 1. exterior hpl R GOGREEN!!NEWEDGEHPLFACADE www.exteriorhpl.com exterior hpl R Authorised Dealer 100 % UV Protected

- 2. ABOUT REZNOCLAD Reznoclad is self-supporting high pressure laminate (HPL) with a decorative surface that is suitable for exteriors. It is fade resistant weather-proofand complieswith standard EN 438. It is entirely made up of layers of phenolic resin & impregnated craft paperswith top decorative layer and UVprotective film. The manufacturing process involves the combining of papers with o applications of high heat (150 c) and high pressure (9 Mpa) in which resin polycondensation takes place. One or both sides can be decorative mixedwith the phenolic resins. exterior hpl R 01

- 3. TYPES OF EXTERIOR PANELS REZNOCLAD panels are available in the following grades for their suitability as per the required applications. • Exterior Cladding Panels (Fire Retardant) • Exterior Cladding Panels • Exterior Cladding Panels (With Anti-graffiti) • Wall and facade linings • Cladding or exhibition building • Sporting and entertainment complexes • Decoration of commercial sites • Residential dwellings • silhouette profiles • fences • Facade Claddings • Balcony Claddings • Partitions • Rear ventilated facades • Ceilings • Outdoor furniture • Public facilities • Playground facilities • Sport facilities • Sun protection • Business entry portals • Functional constructions • Attic Cladding • Awnings REZNOCLAD panels are extremely durable with international styling and a wide range of colours available on both horizontal and vertical designs. Its excellent technical properties make it suitable for the building industries as an ideal alternative to traditional materials. APPLICATION exterior hpl R 02

- 4. CHARACTERISTICS CLEANING & MAINTENANCE HANDLING & STORAGES Reznoclad panel comes with a film on top layer for protection during transportation. During stocking, panels must be stacked horizontally on flat, stable shelfs, the panels to be stored in closed rooms under dry, normal climatic conditions. Cover plates must always be left on the stack. The cover should be weighted down. Any form of dirt or dust between the panels must definitely be avoided. Panels must be lifted and not pushed or pulled over the edge when carrying or loading. For climate differences, keep panels waiting for 24 hours in new climate conditions. With pre- installed fastering elements, care is to be take that the climatic effect is uniform on all sides. Use intermediate layers ofwood or plastic. REGULAR SIZES The protective film applied at factory must be removed from the surface of the panel immediately after installation to the facade. The surface of reznoclad panels repels dust, however over the time it may be necessary to clean their surface with soapy water for better aesthetic over time. WARRANTIES Thanks to practical experience over many year and the high quality of Reznoclad HPL Panels, warranties are available both for the product range in general and for specific projects. More information can be obtained from your local representative. 3050*1300*6mm 2440*1220*6mm Thickness On demand: 4 to 20mm Grain direction Easy to Clean Moisture Resistance Strike Resistance Chemical Effects Resistance Abrassion Resistance High Heat & Fire Resistance Ÿ Ÿ Resistance to atmospheric conditions Ÿ Resistance to swelling in boilingwater Ÿ Fire-resistance Ÿ Physical resistance to strikes and abrasion Ÿ Chemical resistance to mild acids, rain, air pollution Ÿ Wide range ofcolors and patterns Ÿ Easy to care and repair Ÿ Do not contain any harmful substances Resistance to UVrays Ÿ Ÿ Overall lightweight substructure and facade Ÿ dimensional stability and flatness Ÿ Lightweight facade system Ÿ Easier perforation Maximum light fasten exterior hpl R 03

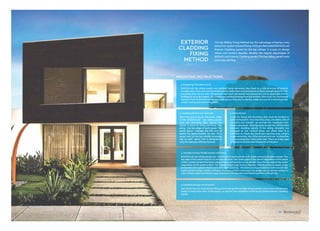

- 5. EXTERIOR CLADDING FIXING METHOD The lap Sliding Fixing Method has the advantage of being a very attractive system ofpanel fixing.With pre-fabricated REZNOCLAD Exterior Cladding panels for the lap sidings. It is easy to design robust and modern facades. Besides the regular advantages of REZNOCLAD Exterior Cladding panels, This lap siding panels looks more eye catching. MOUNTING INSTRUCTIONS 1. PreparingThe Substructure REZNOCLAD lap siding panels are installed using mounting clips fixed to a sub-structure of vertical wooden slats. Each slat must be at least 50 mm wide where two panels join to allow enough space for two mounting clips side by side. The gap between each slat should not exceed 500 mm as applicable to low building of up to 8m height. The panels are installed starting from the bottom. First of all, fit a horizontal base bar. Now fit the first row of mounting clips so they rest on the bar. Make sure you fit 2 mounting clips at eachvertical joint between panels. 2. Installing the first row ofpanels Place the groove along the lower edge of the REZNOCLAD lop siding panels onto the mounting clips. Secure the panels in place by fixing mounting clips along the lop edge of each panel. The panel above overlaps the first row of panels by approximately 25 mm. Fit a screw next to the lop middle mounting clip on each panel. This is designed to stop the sideways shifting ofpanels 3.Vertical joints A slot for Fixing the mounting clips must be located at each vertical joint. Two mounting clips, one either side of the joint, ore needed to provide the necessary hold. Please use proper backing strips to seal the vertical Joint between cladding panels. If the siding elements ore arranged so the vertical Joints ore offset then it is sufficient to install the panel plus backing strip using o single mounting clip. Ifthevertical joints are in a line then two mounting clips need to be used. There must be a gap ofat least 8 mm between the panels at the joint. 4. Outside corners/Inside cornerswith mitre REZNOCLAD lap siding panels can be mitred lor both outside and inside corners. Outside corners: The lap edge of the panel must be 12 mm shorter than the lower edge of the poneI (regardless of the panel width). Inside corners: The lower edge of the panel must be 12 mm shorter than the top edge of the panel (regardless of the panel width). The mitred edges must hove a chamfer. Thesub-struclure needs to be protected with a plastic sheet to prevent water entering. Elements can be installed on both outside and inside corners using a variety of shapes of corner profile. In this case the panels ore cut to size without a mitre. Please make sure there is a gap ofat least 5 mm between each panel and the corner profile. 5. Installing the top row ofpanels Secure the top row of panels by fitting screws along the top edge of each panels. Use screws with painted heads to match the color of the panels, as used for the installation of full-sized Samrat exterior Cladding panels. exterior hpl R 04

- 6. ENVIRONMENT Reznoclad is committed to continuous improvement of environmental performances. These panels are not hazardous to health and does not pollute the environment. It is made up of 70% cellulose fibers and 30% thermosetting resins and does not contain asbestos or heavy metals. These panels does not emit gases, fumes, solvents or liquid substances. Fixing DetailsInstallation System RIVET FIXING SYSTEM exterior hpl R 05

- 7. Woody Streaks 9363 Canyon Monument Oak 9391 American Elm 9354Light Knotty Pine 9322 Princess WalnutArizona Walnuts 9334 9383 Grey Monument OakWisconsin Walnut 9345 9394 exterior hpl R 06

- 8. 9351Brunt Wood9320Mustard Aquatone 9395Straight Wenge9394Oxford Cherry 9381Bengali Mango Dark 9384Versailles Walnut 9807Travetine Marble9806Gold Spray exterior hpl R 07

- 9. 9422White 9420Frosty White 9421​Smoke Grey 9425Black 9423Slate 9424Coffee exterior hpl R 08

- 10. REZNOCLAD PROJECTS TECHNICAL SPECIFICATION S. No. PROPERTIES TEST METHOD ATTRIBUTES OF PERFORMANCE UNITS OF MEASUREMENT RESULTS (AS PER EN438-6) 1. Surface Quality 1.1 Surface Quality EN 438-2.4 Spots, dirt and similar surface 2 2 mm /m 2 202 2 mm /mFibres, hairs & scratches Dimensional Properties Thickness Size Straightness of edge Squareness Flatness EN 438-2.5 EN 438-2.6 EN 438-2.7 EN 438-2.8 EN 438-2.9 2. 2.1 2.2 Thickness Tolerance Length and Width Straightness of edges Squareness Flatness (measured on full-size sheet) mm mm mm/m mm/m mm/m 5 T 8:+ 0, 4 +10/-0 1,5 1,5 6.0 T 10,0:5 Physical Properties3. 3.1 3.2 3.3 3.4 3.5 3.6 3.7 4. 4.1 4.2 5. 5.1 EN ISO 1 78 EN ISO 1 78 EN ISO 527-2 EN ISO 1183 EN 438-2.21 EN 438-2.15 EN 438-2.17 EN 438-2.19 EN 438-2.29 EN 135 01 Stress Stress Stress Density Indent dia. 10mm 2 T < 6mm Drop Height Indent dia. 10mm T 6mm - Drop Height Mass increase - 2 T < 5mm Mass increase - T 5mm Appearance Cumulative dimensional change -2 T 5mm Cumulative dimensional change -T 5mm Thermal Shock Resistance- Appearance Contrast Appearance Test as per EN 13823 (SBI Test) and EN ISO 11925 - 2 (Small-burner Test) Classification - 3 T < 6mm Classification - 6 T < 13mm Mpa Mpa Mpa 3 gm/cm min. min. max.% max.% Rating Longitudinal % Transversal % Longitudinal % Transversal % Rating Grey Scale Rating Rating Classification Classification 9000 80 60 1,35 1400 1800 EGS- 7, EGF- 10 EGS- 7, EGF- 10 4 0.40 0.80 0.30 0.60 4 3 4 B-s2, d0 B-s1, d0 Flexual Modulus Flexual Strength Tensile Strength Density Resistance to impact with large diameter bill Resistance to Wet Conditions Dimensional Stability at elevated temperatures Weather Resistance Requirements Resistance to Climatic Shock Resistance to Artificial Weathering Fire Performances Fire Reaction Classification PERMEABILITY WATER PROTECTION THERMAL INSULATION (ELEMENATION OF HEAT BRIDGE) SOLAR PROTECTION ACOUSTIC PROTECTION BREATHABLE FACADE FOR HEALTHIER BUILDINGS- REZNOCLAD HPL IS HIGHLY SUITED FOR VENTILATED FACADE SYSTEMS. exterior hpl R 09