Rheology and Slot Die Coating Technology by Coating Tech Slot Dies

- 1. RHEOLOGY & SLOT DIE COATING TECHNOLOGY

- 2. SLOT DIE COATING TECHNOLOGY ŌĆó Background ŌĆó System ŌĆó Technique ŌĆó Process ŌĆó Summary

- 3. BACKGROUND ŌĆó Slot die basics ŌĆó Closed system ŌĆó Distribute fluid uniformly ŌĆó Define coat width ŌĆó Maintain temperature

- 4. BACKGROUND ŌĆó Slot die applications ŌĆó Viscosity versus shear rate ŌĆó % Solids ŌĆó Coating thickness ŌĆó Particle size ŌĆó Coating width ŌĆó Line speed ŌĆó Operating temperature

- 5. BACKGROUND ŌĆó Slot die design ŌĆó Rheology ŌĆó Manifold ŌĆó Body sections ŌĆó Fluid flow control

- 6. BACKGROUND RHEOLOGY ŌĆó Viscosity ŌĆó Shear Rate (Stress) o 1-10,000 1/sec

- 7. RHEOLOGY ŌĆó Test methods o ASTM D4440 ’üČ Parallel plate ’üČ Cone and Plate ’üČ Cup and Bob ’üČ Capillary

- 8. GEOMETRIES BOB and CUP CONE and PLATE PARALLEL PLATE DMA Rotational/Oscillatory Rotational/Oscillatory Rotational/Oscillatory Oscillatory, Creep Very low to medium viscosity Low to high viscosity, constant shear rate across the sample Low viscosity to soft solids, curing studies, dispersions Solids, thermo- mechanical analysis, curing, Tg, ŌĆ” Relatively large volume, inertia limitations in oscillatory test Very small volume, measure of normal stresses (elasticity) Very small volume, relatively large gap Stress is force over sample cross section

- 9. BACKGROUND RHEOLOGY ŌĆó Newtonian ŌĆó Polymeric o Shear thinning o Shear thickening ╬Ę ╬│ . ╬Ę ╬│ . ╬Ę ╬│ . ╬Ę ╬│ . ╬Ę ╬│ .

- 10. BACKGROUND RHEOLOGY ŌĆó Process Knowledge o GŌĆÖ (storage) o GŌĆØ (loss) o tan ╬┤

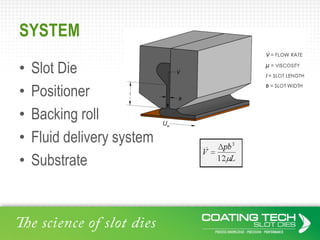

- 11. SYSTEM ŌĆó Slot Die ŌĆó Positioner ŌĆó Backing roll ŌĆó Fluid delivery system ŌĆó Substrate

- 12. SYSTEM ŌĆó Slot Die o Manifold design o Manufacturing tolerances o Lip offset o Lip geometry

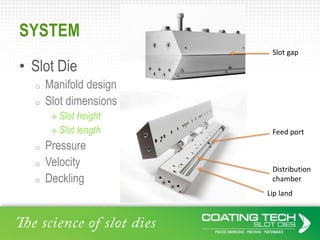

- 13. SYSTEM ŌĆó Slot Die o Manifold design o Slot dimensions ’üČ Slot height ’üČ Slot length o Pressure o Velocity o Deckling Distribution chamber Feed port Slot gap Lip land

- 14. SYSTEM ŌĆó Slot Die o Manifold design ’üČ Infinite cavity (Newtonian) ’üČ Coat hanger (Polymeric) o Goal = uniform volumetric flow rate and pressure across coat width o Range of viscosity (families)

- 15. SYSTEM ŌĆó Slot Die o Fixed lip o Flex lip o Rotary rod

- 16. SYSTEM ŌĆó Positioner o Attack angle o Position to roll o Repeatability

- 17. SYSTEM ŌĆó Backing roll o Diameter o TIR o Cocentricity o Cylindricity

- 18. SYSTEM ŌĆó Fluid Delivery System o Positive displacement o Rheology of fluid o Density o Particle size o Shear sensitivity

- 19. SYSTEM ŌĆó Substrate o Variation (RTY) o Surface energy o Surface treatment o Vacuum box o Tension control

- 20. SYSTEM ŌĆó Vacuum System Vacmin = (12┬ĄVLD)/dD 3 * ((dD/2)-h)) minimum vacuum required for coating thickness h (LD and dD are downstream lip length and slot die to substrate gap)

- 21. TECHNIQUE

- 23. TECHNIQUE ŌĆó Tensioned web o Elasto-hydrodynamic interaction ’üČ Web tension ’üČ Line speed/flow rate ’üČ Wet coating thickness ’üČ Wrap angles ’üČ Lip geometry ’üČ Web penetration

- 24. TECHNIQUE ŌĆó Curtain coating o Advantages ’üČ Large gap (irregular surfaces) ’üČ Reduced lines and streaks ’üČ Increased fluid velocity (hydrodynamic assist) ’üČ Higher line speed o Disadvantages ’üČ Air ’üČ Vibration ’üČ Minimum line speed & flow rate

- 25. PROCESS ŌĆó Full width coating

- 26. PROCESS ŌĆó Lane coating o Deckling o Body shim o Lip shims o Spreading (experimentation)

- 27. PROCESS ŌĆó Intermittent coating o Continuous o Discrete panel o IP o Process limitations ’üČ Head ’üČ Tail ’üČ Line speed ’üČ Start/stop phenomenon

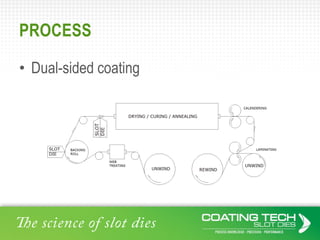

- 28. PROCESS ŌĆó Multi-layer coating o 2-3 layers in typical slot die design o ║▌║▌▀Ż die design accommodates more layers o Separate fluid delivery system for each layer o Combined outside the slot exit Žātop < Žābottom (surface energy stability)

- 30. SUMMARY ŌĆó System ŌĆó Technique ŌĆó Process