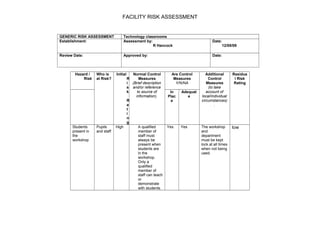

Risk assessment

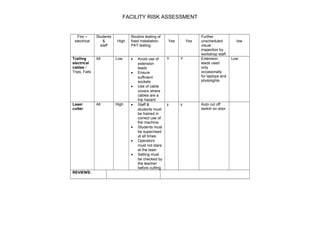

- 1. FACILITY RISK ASSESSMENT GENERIC RISK ASSESSMENT Technology classrooms Establishment: Assessment by: R Hancock Date: 12/08/09 Review Date: Approved by: Date: Hazard / Risk Who is at Risk? Initial Ri sk Rati ng Normal Control Measures (Brief description and/or reference to source of information). Are Control Measures Y/N/NA Additional Control Measures (to take account of local/individual circumstances) . Residua l Risk Rating In Plac e Adequat e Students present in the workshop Pupils and staff High A qualified member of staff must always be present when students are in the workshop. Only a qualified member of staff can teach or demonstrate with students. Yes Yes The workshop and department must be kept lock at all times when not being used. low

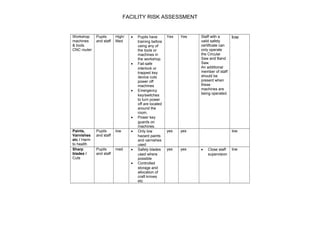

- 2. FACILITY RISK ASSESSMENT Workshop machines & tools. CNC router Pupils and staff High/ Med · Pupils have training before using any of the tools or machines in the workshop. · Fail-safe interlock or trapped key device cuts power off machines · Emergency key/switches to turn power off are located around the room. · Power key guards on machines. Yes Yes Staff with a valid safety certificate can only operate the Circular Saw and Band Saw. An additional member of staff should be present when these machines are being operated. low Paints, Varnishes etc / Harm to health Pupils and staff low · Only low hazard paints and varnishes used yes yes low Sharp blades / Cuts Pupils and staff med · Safety blades used where possible · Controlled storage and allocation of craft knives etc yes yes · Close staff supervision low

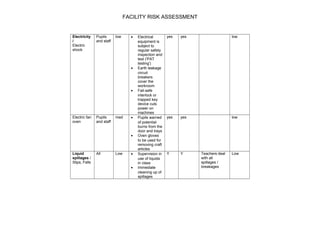

- 3. FACILITY RISK ASSESSMENT Electricity / Electric shock Pupils and staff low · Electrical equipment is subject to regular safety inspection and test ('PAT testing') · Earth leakage circuit breakers cover the workroom · Fail-safe interlock or trapped key device cuts power on machines yes yes low Electric fan oven Pupils and staff med · Pupils warned of potential burns from the door and trays · Oven gloves to be used for removing craft articles yes yes low Liquid spillages / Slips, Falls All Low · Supervision in use of liquids in class · Immediate cleaning up of spillages Y Y Teachers deal with all spillages / breakages Low

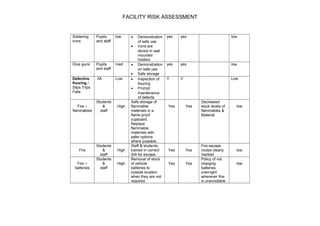

- 4. FACILITY RISK ASSESSMENT Soldering irons Pupils and staff low · Demonstration of safe use · Irons are stored in wall mounted holders yes yes low Glue guns Pupils and staff med · Demonstration on safe use · Safe storage yes yes low Defective flooring / Slips Trips Falls All Low · Inspection of flooring · Prompt maintenance of defects Y Y Low Fire ~ flammables Students & staff High Safe storage of flammable materials in a flame proof cupboard. Replace flammable materials with safer options where possible. Yes Yes Decreased stock levels of flammables & Material low Fire Students & staff High Staff & students trained in correct drill for escape. Yes Yes Fire escape routes clearly marked low Fire ~ batteries Students & staff High Removal of stock of vehicle batteries to outside location when they are not required. Yes Yes Policy of not charging batteries overnight whenever this is unavoidable. low

- 5. FACILITY RISK ASSESSMENT Fire ~ electrical Students & staff High Routine testing of fixed installation. PAT testing. Yes Yes Further unscheduled visual inspection by workshop staff. low Trailing electrical cables / Trips, Falls All Low · Avoid use of extension leads · Ensure sufficient sockets · Use of cable covers where cables are a trip hazard Y Y Extension leads used only occasionally for laptops and photolights Low Laser cutter All High · Staff & students must be trained in correct use of the machine. · Students must be supervised at all times. · Operators must not stare at the laser · Setting must be checked by the teacher before cutting. y y Auto cut off switch on door REVIEWS:

- 6. FACILITY RISK ASSESSMENT DATE OF REVIEW: REVIEWED BY: COMMENTS: DATE OF REVIEW: REVIEWED BY: COMMENTS: DATE OF REVIEW: REVIEWED BY: COMMENTS:

- 7. FACILITY RISK ASSESSMENT DATE OF REVIEW: REVIEWED BY: COMMENTS: DATE OF REVIEW: REVIEWED BY: COMMENTS: DATE OF REVIEW: REVIEWED BY: COMMENTS: