RMT VMCompany Profile

- 1. COMPANY PROFILE 1

- 2. INTRODUCTION The company is one of the oldest valve manufacturer in Italy. Since 1950 design and manufacture were concentrated on lubricated plug valves in standard and inverted pressure-balanced designs. For 40 years the company operated successfully improving its skills and capabilities, up to the beginning of the â90s when the company w as liquidated due to market changes and the growing attention of the owners to forgings and ball valves production. In 1998 the activity found a new beginning with the name âLa Valvomeccanica S.p.A.â, incorporated in Solbiate Olona (VA) as a public limited company specialized in small and medium ball valves. In the same year, âRMT Valves s.r.l.â w as established in Voghera (PV), as a trading company supplying service to major w orldwide Engineering & Construction companies for all types of on-off valves: ball, gate, globe, check, butterfly and plug. In 2008 the good collaboration betw een the tw o companies led to the merger of the tw o companies into âRMT Valvomeccanica s.r.l.â. RMT VALVOMECCANICA is included in the GIVA group, an Italian group founded by Mr. Antonio Vienna in 1962 in Northern Italy, which performed in 2008 a turnover exceeding 650 Million Euro. Actually the group includes steel mills, such as Italfond, and important forge masters, such as Forgiatura A.Vienna, which can supply big forgings up to 120 tons and shell rings up to 8 meters in diameter, with a wide range of materials. Supported by the international experience and the innovation of the group, in the last years the company improved products quality and customers satisfaction. Moreover RMT Valvomeccanica has risen to the top of the market thanks to its competitiveness and the capacity to adapt to the continuous evolutions occurring within the market itself. 2

- 3. The factory and headquarter of the company are located in the town of Solbiate Olona, just North of Milan in the very heart of the Italian and European valve industry, at a short driving distance from most of the main sub suppliers of raw materials and components. Moreover Solbiate Olona is easy to get to from downtown Milan as w ell as from the tw o main airports of Malpensa and Linate. PRODUCT RANGE RMT VALVOMECCANICA s.r.l. is present in the small and big sized ball valve market, dedicated to the design and manufacture of ball valves in a multiplicity of materials: carbon and stainless steels, duplex and super duplex, as well as inconel and incoloy. Our valves are currently employed w orldwide in many applications such as oil & gas, chemical, petrochemical, naval, pharmaceutical, power, offshore etc. B ALL VALVE â FLOAT ING SIDE ENTRY â TYPE FSE Tw o pieces split bolted body side entry floating ball valves ASME class 150-300-600- 900-1500-2500 flanged butt w elding or hub ended (on request), anti-blow out stem, antistatic device, design triple stem seals, double body seals, fire-safe design, ISO 5211 drilling for top mounting (âĨ 1Â―â), construction and testing according to API 6D, ASME B 16.34, PED and BS 6755. Size range From Â―â to 8â full and reduced bore Suitable for Std. service Cryogenic service High temperature service Be operable with every actuation 3

- 4. B ALL VALVE â TRUNNION M OUNT ED SIDE ENTRY â TYPE TSE Tw o & three pieces split bolted body side entry trunnion mounted ball valves ASME class 150-300-600-900-1500- 2500 / API 2000 to 10000 flanged or hub ended (on request), anti-blow -out stem, antistatic device, design triple stem seals, double body seals, fire-safe design, ISO 5211 drilling for top mounting (âĨ 1Â―â), construction and testing according to BS 5351/API 6D. Size range From 2â to 60â B ALL VALVE â TRUNNION M OUNT ED TOP ENTRY â TYPE TTE One piece cast body construction, top entry trunnion mounted ball valves ASME class 150-300-600-900-1500-2500 flanged, butt w elding or hub ended (on request), anti-blow -out stem, antistatic device, design triple stem seals, double body seals, fire-safe design, ISO 5211 drilling for top mounting (âĨ 1Â―â), construction and testing according to BS 5351/API 6D Size range From 2â to 56â 4

- 5. B ALL VALVE â TRUNNION M OUNT ED FULLY W ELDED â TYPE TSW One piece cast body construction, fully welded trunnion mounted ball valves ASME class 150-300-600-900 butt w elding or hub ended, anti-blow -out stem, antistatic device, design triple stem seals, double body seals, fire-safe design, ISO 5211 drilling for top mounting (âĨ 1Â―â), construction and testing according to BS 5351/AP I 6D Size range From 2â to 60â B ALL VALVE â D OUBLE BLOCK & BLEED â TYPE DBB One piece bolted body construction with tw o balls, trunnion mounted side entry ball valves ASME class 150-300-600-900- 1500-2500 flanged, hub ended, anti-blow - out stem, antistatic device, design triple stem seals, double body seals, fire-safe design, ISO 5211 drilling for top mounting (âĨ 1Â―â), construction and testing according to BS 5351/API 6D Size range From 2â to 24â B ALL VALVE â SUBSEA One piece cast body construction, trunnion mounted side entry ball valves ASME class 150- 300-600-900-1500-2500 flanged, hub ended, anti- blow -out stem , antistatic device , design triple stem seals, double body seals, fire-safe design, ISO 5211 drilling for top mounting (âĨ 1Â―â), construction and testing according to BS 5351/AP I 6D Size range From 2â to 48â 5

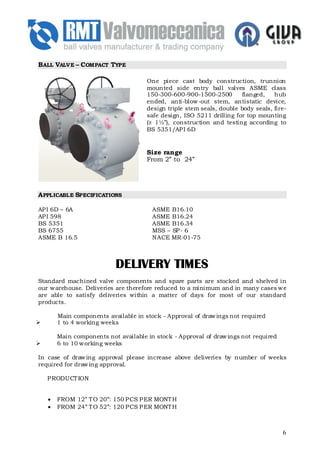

- 6. B ALL VALVE â COMPACT TYPE One piece cast body construction, trunnion mounted side entry ball valves ASME class 150-300-600-900-1500-2500 flanged, hub ended, anti-blow -out stem, antistatic device, design triple stem seals, double body seals, fire- safe design, ISO 5211 drilling for top mounting (âĨ 1Â―â), construction and testing according to BS 5351/AP I 6D Size range From 2â to 24â A PPLICABLE SPECIFICATIONS AP I 6D â 6A ASME B16.10 AP I 598 ASME B16.24 BS 5351 ASME B16.34 BS 6755 MSS â SP - 6 ASME B 16.5 NACE MR-01-75 DELIVERY DELIVERY TIMES Standard machined valve components and spare parts are stocked and shelved in our w arehouse. Deliveries are therefore reduced to a minimum and in many cases w e are able to satisfy deliveries within a matter of days for most of our standard products. Main components available in stock - Approval of draw ings not required 1 to 4 working weeks Main components not available in stock - Approval of draw ings not required 6 to 10 w orking weeks In case of draw ing approval please increase above deliveries by number of weeks required for draw ing approval. P RODUCT ION âĒ FROM 12â T O 20â: 150 P CS P ER MONT H âĒ FROM 24â T O 52â: 120 P CS P ER MONT H 6

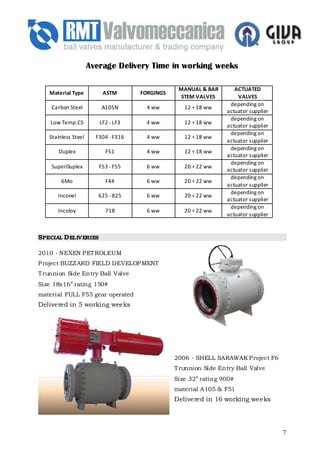

- 7. Average Delivery Time in working weeks MANUAL & BAR ACTUATED Material Type ASTM FORGINGS STEM VALVES VALVES depending on Carbon Steel A105N 4 ww 12 ÷ 18 ww actuator supplier depending on Low Temp.CS LF2 - LF3 4 ww 12 ÷ 18 ww actuator supplier depending on Stainless Steel F304 - F316 4 ww 12 ÷ 18 ww actuator supplier depending on Duplex F51 4 ww 12 ÷ 18 ww actuator supplier depending on SuperDuplex F53 - F55 6 ww 20 ÷ 22 ww actuator supplier depending on 6Mo F44 6 ww 20 ÷ 22 ww actuator supplier depending on Inconel 625 - 825 6 ww 20 ÷ 22 ww actuator supplier depending on Incoloy 718 6 ww 20 ÷ 22 ww actuator supplier SPECIAL D ELIVERIES 2010 - NEXEN P ET ROLEUM P roject BUZZARD FIELD DEVELOP MENT T runnion Side Entry Ball Valve Size 18x16â rating 150# material FULL F55 gear operated Delivered in 5 working weeks 2006 - SHELL SARAWAK P roject F6 T runnion Side Entry Ball Valve Size 32â rating 900# material A105 & F51 Delivered in 16 working weeks 7

- 8. CERTIFICATIONS CERTIFICATIONS - UNI EN ISO 9001:2008 â TÅV Italia Srl - CE MARK â TÅV Italia Srl - API MONOGRAM â American Petroleum Institute - SIL 3 â IEC 61508:2000 Functional Safety Management System - ATEX certificate 94/9/CE â DNV Modulo Uno 8

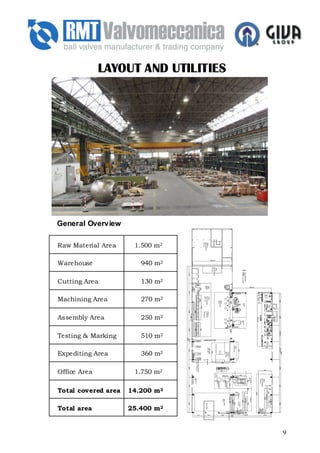

- 9. LAYOUT AND UTILITIES General Overview Raw Material Area 1.500 m2 Warehouse 940 m2 Cutting Area 130 m2 Machining Area 270 m2 Assembly Area 250 m2 Testing & Marking 510 m2 Expediting Area 360 m2 Office Area 1.750 m2 Total covered area 14.200 m2 Total area 25.400 m2 9

- 10. PROCESS EQUIPMENT Lifting âĒ 1 x 30 tons Overhead Double Girder Crane (indoor) âĒ 2 x 20 tons Overhead Double Girder Crane (1 indoor + 1 outdoor) âĒ 1 x 5 tons Overhead Double Girder Crane (indoor) âĒ 4 x 2 tons Wall Jib Cranes (assembling area) âĒ 3 x electric rechargeable Forklifts (2,5 tons LINDE + 4,8 tons LINDE + 12 tons KAREER) âĒ 6 x manual transpallets max 2500 kgs âĒ 4 x electric transpallets max 1400 kgs LINDE RMT VM - Control Pane l of CNC Machining PRODUCTION: âĒ 2 x CNC w ork-centre MORI SEIKI (Â―â to 10â - 12 pallets) âĒ 2 x Automatic cutting machines max. à 360mm RMT VM - CNC workce ntre (Â―â to 10â -12 palle ts). AUXILIARY: âĒ 1 x Manual parallel lathe H 300 x 1500mm âĒ 1 x Manual cutting machine max à 60mm âĒ 2 x Vertical drilling machines âĒ 1 x Radial drilling machine âĒ 3 x Grinding machines RMT VM â Automatic cutting machines max. à 360mm âĒ 1 x Ball polishing machine âĒ 1 x P ress for seat insert Assembling âĒ Hydraulic torque wrenches (rings and bodies up to 41.893 Nm) & 3 pump units P ROTEC & MAPP T OOLS up to 60 l and 700 bar âĒ 4 x benches for small valves assembly âĒ 2 x equipped areas for big valves assembly 10

- 11. TESTING EQUIPMENT Material Tests (carried out on site): âĒ MP I - Magnetic P article T est (MAGISCOP E 3000 silver yoke) âĒ DYP - Dye P enetrant Examination âĒ UT - Ultrasonic Test (KRAUT KRAMER) âĒ P MI - P ositive Material Identification (Spectrometer NIT ON Analyzer XL2 800) âĒ Hardness Test INSTRUMENTS: RMT VM - Test Bench âĒ Roughness tester MIT UTOYO âĒ Measuring 3D machine CAM2 âĒ Altimeter TESA âĒ Comparator MIT UT OYO âĒ Alesameter MAHR âĒ Micrometer MIT UTOYO âĒ X-RAY view box 50000 Cd/mq SEMAT âĒ T emperature Recorder YOKOGAWA âĒ Dualscope for painting max 2000 m FISCHER RMT VM â Test Bench Valve Tests âĒ 2 x Pneumatic & Hydraulic Test Benches ( Â―â to 10â) [one w ith threaded ends] âĒ 1 x Pneumatic & Hydraulic T est Bench ( 6â to 24â ) âĒ 1 x Pneumatic & Hydraulic T est Bench ( 6â to 36â ) âĒ 1 x Pneumatic & Hydraulic T est Bench (16â - 48â ) bigger sizes are tested using blind RMT VM â Test Bench counter flanges âĒ P ressure gauges max 2000 bar âĒ Plug T est gauges up to 48â âĒ T orque verification equipment ALKITRONIC & Dynamometric Wrenches max 2000 Nm âĒ Flow meter ASA for Pneumatic T est (for metal to metal valves) âĒ Cryogenic test equipment (bath up to 12â valves) âĒ Fugitive emission test equipment (Helium Mass Spectrometer & Vacuum tester ESA) âĒ Bunker for valve gas testing up to 36â 600lbs (28â AP I 15000) RMT VM â Bun ker for Gas Testing 11

- 12. Tests carried out by sister companies: âĒ Ultrasonic test âĒ P MI Corrosion test âĒ RX Radiographic Test âĒ Mechanical and chemical tests âĒ DYE Liquid Penetrant âĒ MP I Magnetic P article âĒ Laboratory examination Marking, Packing & Shipping âĒ CNC Marking machine (low stress) âĒ Electric & Pneumatic tools for P acking âĒ 1 x 40 tons bridge crane âĒ 1 x 1500 kgs max balance âĒ 1 x 10 kgs balance SUPPORTING SERVICES RMT Electronic Data System consist of the following HW: 1 Application Server 1 File Server (MET ODO) 1 File Server (DNS) 1 File Server / APP L.SVR. (P ro-Engineering CAD) 2 Netw orks Access Storage (for daily backup) 2 main Hub-Sw itch 1 Gbit/s 4 secondary Hub-Sw itch 100 Mbit/s 3 Access point for wireless comunication 40 netw ork P C 6 A3/A4 Copier - Scanner - Fax simile (multi-task) 4 color laser printer A4 for higher number of copies an ink jet colour printer for larger format A3 an ink jet colour printer A4 format only Analog Switchboard hub configured by 16 external lines and 22 extension a router ADSL for Internet access (1 Mb band guarantee) a firew all cisco following SW: Operating System Window s XP , Window s Vista, Window s 7 A simultaneously accessible netw ork EDP System for 20 w orkstations MET ODO 4 licenses of Pro-Engineer CAD program 1 license of Tell CAD program other program able to realise informative data flow show in the manual and procedure and following internet connections: internet website www.rmtvalvomeccanica.com main E-mail: info@rmtvalvomeccanica.com 12

- 13. GIVA GROUP The GIVA Group (Gruppo Industriale Vienna Antonio), with tw o steel mills and five forge masters located in various parts of Northern Italy, today holds the National record for the volume of annual output. Experience and innovation are the particular qualities which best identify the groupâs companies, which are leaders in the sectors in which they operate. STEEL - STEEL MILLS - PRODUCTION CAPACITY T ONS PER YEAR: 60.000 tons Nunki Steel P roduction of Carbon Steel ingots: 1 ingot max 80 tons each 90 minutes Italfond Italfond S.p.A. manufactures forged ingots and bars made of Stainless Steel and Special Alloys, and currently ranks among the w orldâs most technologically advanced steel mills. Stainless Steel & exotic materials bars and ingots up to 21.500 kg âĒ 30 tons electric arc furnace, AOD converter and automatic plant for handling ferroalloys and scrap âĒ VAR equipment for re-melting machine âĒ Hydraulic presses + manipulators âĒ Rotary forging machine (the largest in Italy) âĒ Remote controlled heating furnaces âĒ Heat treatment furnaces & cooling tanks up to 80 tons gross weight âĒ Lathes & automatic peelers for bars up to 18â diam. âĒ 2 automatic grinding machines 13

- 14. RAW MATERIALS CARBON STEELS ASTM A105N ASTM A350 LF2 ASTM A350 LF3 [-101° IMPACT TESTED] AISI 4140 F60 STAINLESS STEELS ASTM A 182 F304 ASTM A 182 F6 ASTM A 182 F316 ASTM A 182 F317 ASTM A 182 F316L ASTM A 182 F316TI ASTM A 182 F316LN ASTM A 182 F321 ASTM A 182 F347 A564 GR. 630 (UNS S17400), 17-4-PH A479 XM19 (NITRONIC 50) DUPLEX STAINLESS STEELS ASTM A 182 F51 (UNS S31803) SUPER DUPLEX STAINLESS STEELS ASTM A 182 F53 (UNS S32750) ASTM A 182 F55 (UNS S39276) 6 MO ASTM A 182 F44 (UNS S31254) NICKEL ALLOYS INCOLOY 825 (UNS N8825) INCOLOY 625 (UNS N6625) INCONEL 718 (UNS N07718 B637 GR718) INCONEL X 750 (UNS S07750 B637 GR688) 14

- 15. - FORGE MASTERS - PRODUCTION CAPACITY T ONS PER YEAR: 200.000 tons FORGING P RODUCT ION RELEVANT TO VALVE MARKET : BODIES, CLOSURES, BALLS: FROM 56â TO 60â, 5 PCS PER WEEK Example: week 41,2008 â P roduced in 5 days 60 balls 56â 600lbs in LF2 Forgiatura A.Vienna Forgiatura A.Vienna operates in the heavy rolling and forging sector and is the largest company in GIVA Group. Thanks to the continual technological investments, the company today stands out d ue to its production capacity for large size forgings, both heavy-rolled and open-die-forged products. In 2007 Forgiatura A.Vienna became the leader in its field for the quantity and quality of production of shell rings for major petrolchemical projects. PRODUCTION: Forgings up to 120.000 Kgs Rings up to 9.000 mm in diameter M aximum l ength: 12 m EQUIP MENT: 10.000 - 6.000 and 3.500 tons presses CALAM 2000 rolling machine Wagner rolling mill Manipulators up to 90 tons P re-forging furnaces Cutting edge rolling technology is used to turn out items w eighing up to 120 metric tons max diameter 9.000 mm with height up to 3.000 mm. Heat treatment furnaces - salts - baths Up to mm 8000 x 12000 x 3500 h up to 1100°C 15

- 16. La Forgia di Bollate P roduction range: forging w eight 100 to 18.000 kgs max. length bars/shafts 8.000 mm max. Ã discs 2.200 mm Ring lamination range: max. Ã 2.500 mm max. height 550 mm max. weight 2.500 kgs Forges 3.500 tons oil-pressure press 5.000 tons hydraulic press 6 manipulators up to 45-ton vertical lathes horizontal lathes milling machines CNC machining centres Nuova OFAR 6,000 T ons Press 80 T ons manipulator 50 T ons integrated manipulator 2,500 T ons Press 20 T ons manipulator 20 T ons integrated manipulator Vertical saw cutting Max. height 2,000 mm Max. width 2,000mm Horizontal saw cutting Max. length 6,000 mm Max. width 2,000mm Heat T reatment equipments P roducts up to 80 tons Maximum length: 22m 16

![TESTING EQUIPMENT

Material Tests (carried out on site):

âĒ MP I - Magnetic P article T est

(MAGISCOP E 3000 silver yoke)

âĒ DYP - Dye P enetrant Examination

âĒ UT - Ultrasonic Test (KRAUT KRAMER)

âĒ P MI - P ositive Material Identification

(Spectrometer NIT ON Analyzer XL2 800)

âĒ Hardness Test

INSTRUMENTS: RMT VM - Test Bench

âĒ Roughness tester MIT UTOYO

âĒ Measuring 3D machine CAM2

âĒ Altimeter TESA

âĒ Comparator MIT UT OYO

âĒ Alesameter MAHR

âĒ Micrometer MIT UTOYO

âĒ X-RAY view box 50000 Cd/mq SEMAT

âĒ T emperature Recorder YOKOGAWA

âĒ Dualscope for painting max 2000 m

FISCHER

RMT VM â Test Bench

Valve Tests

âĒ 2 x Pneumatic & Hydraulic Test

Benches

( Â―â to 10â) [one w ith threaded ends]

âĒ 1 x Pneumatic & Hydraulic T est Bench

( 6â to 24â )

âĒ 1 x Pneumatic & Hydraulic T est Bench

( 6â to 36â )

âĒ 1 x Pneumatic & Hydraulic T est Bench

(16â - 48â )

bigger sizes are tested using blind RMT VM â Test Bench

counter flanges

âĒ P ressure gauges max 2000 bar

âĒ Plug T est gauges up to 48â

âĒ T orque verification equipment

ALKITRONIC & Dynamometric

Wrenches max 2000 Nm

âĒ Flow meter ASA for Pneumatic T est

(for metal to metal valves)

âĒ Cryogenic test equipment (bath up to

12â valves)

âĒ Fugitive emission test equipment

(Helium Mass Spectrometer &

Vacuum tester ESA)

âĒ Bunker for valve gas testing up to 36â

600lbs (28â AP I 15000)

RMT VM â Bun ker for Gas Testing

11](https://image.slidesharecdn.com/companyprofile-1283947371431-phpapp01/85/RMT-VMCompany-Profile-11-320.jpg)

![RAW MATERIALS

CARBON STEELS

ASTM A105N

ASTM A350 LF2

ASTM A350 LF3 [-101° IMPACT TESTED]

AISI 4140

F60

STAINLESS STEELS

ASTM A 182 F304

ASTM A 182 F6

ASTM A 182 F316

ASTM A 182 F317

ASTM A 182 F316L

ASTM A 182 F316TI

ASTM A 182 F316LN

ASTM A 182 F321

ASTM A 182 F347

A564 GR. 630

(UNS S17400), 17-4-PH

A479 XM19 (NITRONIC 50)

DUPLEX STAINLESS STEELS

ASTM A 182 F51 (UNS S31803)

SUPER DUPLEX STAINLESS STEELS

ASTM A 182 F53 (UNS S32750)

ASTM A 182 F55 (UNS S39276)

6 MO

ASTM A 182 F44

(UNS S31254)

NICKEL ALLOYS

INCOLOY 825 (UNS N8825)

INCOLOY 625 (UNS N6625)

INCONEL 718

(UNS N07718 B637 GR718)

INCONEL X 750

(UNS S07750 B637 GR688)

14](https://image.slidesharecdn.com/companyprofile-1283947371431-phpapp01/85/RMT-VMCompany-Profile-14-320.jpg)