Robust Design And Variation Reduction Using DiscoverSim

- 1. Robust Design and Variation Reduction Using DiscoverSimŌäó John Noguera CTO & Co-Founder SigmaXL, Inc. www.SigmaXL.com September 24, 2012 Copyright ┬® 2012, SigmaXL, Inc.

- 2. Robust Design and Variation Reduction Using DiscoverSimŌäó: Agenda ’ü¼ Introduction to DiscoverSim ’ü¼ Monte Carlo Simulation ’ü¼ Stochastic Global Optimization ’ü¼ Case Study: Robust Design of Shut-Off Valve Spring Force ’ü¼ Case Study: Catapult Variation Reduction 2

- 3. Introduction to DiscoverSim ’ü¼ Variation reduction and robust design are a vital part of Design for Six Sigma (DFSS). ’ü¼ While Design of Experiments (DOE) play an important role in DFSS, in order to achieve optimal results, one must also employ the tools of Monte Carlo simulation and optimization. ’ü¼ DiscoverSim is a new, low cost, powerful Excel add-in tool by SigmaXL that will enable these improvements (even with complex, non-linear models). 3

- 5. Introduction to DiscoverSim ’ü¼ Stochastic Global Optimization can be achieved using a hybrid methodology of Dividing Rectangles (DIRECT), Genetic Algorithm, and Sequential Quadratic Programming. ’ü¼ Simulation and optimization speed are realized using DiscoverSim's Excel Formula Interpreter. ’ü¼ Utilizes Gauss Engine by Aptech. ’ü¼ Common Object Interface (COI) by Econotron Software to implement an Excel spreadsheet in Gauss Engine. ’ü¼ The Gauss Random Number Generator is the ŌĆ£KISS+MonsterŌĆØ random number generator developed by George Marsaglia. This algorithm produces random integers between 0 and 232 ŌĆō 1 and has a period of 108859. 5

- 7. Monte Carlo Simulation We start with the Y = f(X) Model, also known as the ŌĆ£Transfer FunctionŌĆØ: X Process Y ’ü¼ The Y = f(X) model should be based on theory, process knowledge, or the prediction formula of a designed experiment or regression analysis. ’ü¼ This prediction equation should be validated prior to use in DiscoverSim: ŌĆ£All models are wrong, some are usefulŌĆØ ŌĆō George Box. ’ü¼ The results of any Monte Carlo Simulation/Optimization should also be validated with further experimentation or use of prototypes. 7

- 8. Monte Carlo Simulation ’ü¼ After the Y = f(X) relationship has been validated, an important question that then needs to be answered is: ŌĆ£What does the distribution of Y look like when I cannot hold X constant, but have some uncertainty in X?ŌĆØ In other words, ŌĆ£How can I quantify my risk?ŌĆØ. ’ü¼ Monte Carlo simulation comes in to solve the complex problem of dealing with uncertainty by ŌĆ£brute forceŌĆØ using computational power. ’ü¼ The Monte Carlo method was coined in the 1940s by John von Neumann, Stanislaw Ulam and Nicholas Metropolis, while they were working on nuclear weapon projects in the Los Alamos National Laboratory. It was named in homage to Monte Carlo casino, a famous casino, where Ulam's uncle would often gamble away his money. 8

- 9. Monte Carlo Simulation The following diagram illustrates a simple Monte Carlo simulation using DiscoverSim with three different input distributions (XŌĆÖs also known as ŌĆ£AssumptionsŌĆØ) Y = A1 + A2 + A3 10,000 Replications A random draw is performed from each input distribution, Y is calculated, and the process is repeated 10,000 times. The histogram and descriptive statistics show the simulation results. 9

- 10. Selecting a Distribution ’ü¼ Selecting the correct distribution is a critical step towards building a useful model. ’ü¼ The best choice for a distribution is one based on known theory, for example the use of a Weibull Distribution for reliability modeling. ’ü¼ A common distribution choice is the Normal Distribution, but this assumption should be verified with data that passes a normality test with a minimum sample size of 30; preferably 100. 10

- 11. Selecting a Distribution ’ü¼ If data is available and the distribution is not normal, use DiscoverSimŌĆÖs Distribution Fitting tool to find a best fit distribution. ’ü¼ Alternatively, the Pearson Family Distribution allows you to simply specify Mean, StdDev, Skewness and Kurtosis. 11

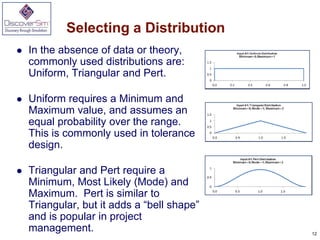

- 12. Selecting a Distribution ’ü¼ In the absence of data or theory, commonly used distributions are: Uniform, Triangular and Pert. ’ü¼ Uniform requires a Minimum and Maximum value, and assumes an equal probability over the range. This is commonly used in tolerance design. ’ü¼ Triangular and Pert require a Minimum, Most Likely (Mode) and Maximum. Pert is similar to Triangular, but it adds a ŌĆ£bell shapeŌĆØ and is popular in project management. 12

- 13. Specifying Correlations ’ü¼ DiscoverSim allows you to specify correlations between any inputs. DiscoverSim utilizes correlation copulas to achieve the desired Spearman Rank correlation values. ’ü¼ The following surface plot illustrates how a correlation copula results in a change in the shape of a bivariate (2 input) normal distribution: 13

- 14. Optimization: Stochastic Versus Deterministic ’ü¼ Monte-Carlo simulation enables you to quantify risk, whereas stochastic optimization enables you to minimize risk. ’ü¼ Deterministic optimization is a commonly used tool to find a minimum or maximum (e.g., Excel Solver) but it does not take uncertainty into account. ’ü¼ Stochastic optimization will not only find the optimum X settings that result in the best mean Y value, it will also look for a solution that will reduce the standard deviation. ’ü¼ Stochastic optimization looks for a minimum or maximum that is robust to variation in X, thus reducing the transmitted variation in Y. This is referred to as ŌĆ£Robust Parameter DesignŌĆØ in DFSS. 14

- 15. Optimization: Robust Parameter Design ŌĆō Catapult Example 15

- 16. Optimization: Local Versus Global The following surface plot illustrates a function with local minima and a global minimum: 16

- 17. Optimization: Local Versus Global ’ü¼ Local optimization methods are good at finding local minima, use derivatives of the objective function to find the path of greatest improvement, and have fast convergence. However they require a smooth response so will not work with discontinuous functions. ’ü¼ DiscoverSim uses Sequential Quadratic Programming (SQP) for local optimization. 17

- 18. Optimization: Local Versus Global ’ü¼ Global optimization finds the global minimum, and is derivative free, so will work with discontinuous functions. However because of the larger design space, convergence is much slower than that of local optimization. ’ü¼ DiscoverSim uses DIRECT (Dividing Rectangles) and Genetic Algorithm (GA) for global optimization. ’ü¼ A hybrid of the above methodologies is also available starting with DIRECT to do a thorough initial search, followed by GA, and then fine tuning with SQP. 18

- 19. Hiwa, S., T. Hiroyasu and M. Miki. ŌĆ£Hybrid Optimization Using DIRECT, GA, and SQP for Global ExplorationŌĆØ, Doshisha University, Kyoto, Japan. 19

- 20. DiscoverSim Components of Optimization ’ü¼ Input Control: The permissible range for the control is specified, and the control, which unlike an input distribution, has no statistical variation. ’ü¼ Think of this as a control knob like temperature. ’ü¼ This is also known as a ŌĆ£Decision VariableŌĆØ. ’ü¼ An input control can be referenced by a constraint and/or an output function. ’ü¼ It is possible to have a model that consists solely of controls with no input distributions. (In this case, the optimization is deterministic, so the number of replications, n, should be set to 1.) ’ü¼ An input control can be continuous or discrete integer. 20

- 21. DiscoverSim Components of Optimization ’ü¼ Constraint: A constraint can only be applied to an Input Control or calculation based on Input Control: ’ü¼ A constraint cannot reference an Input Distribution or Output Response. (Constraints for Outputs, also known as Requirements, will be added in Version 2.) ’ü¼ A constraint cannot be a part of the model equation (i.e., an output cannot reference a constraint). ’ü¼ Constraints can be simple linear or complex nonlinear. ’ü¼ Each constraint will contain a function of Input Controls or Parameter Monitors on the Left Hand Side (LHS), and a constant on the Right Hand Side (RHS). 21

- 22. DiscoverSim Optimization Metrics Optimization Goal: Minimize Maximize Multiple Output Weighted Sum Deviation from Target Weighted Sum Desirability Metric: Statistic: Mean Mean Mean Mean Median Median 1st quartile 1st quartile 3rd quartile 3rd quartile Minimum Minimum Maximum Maximum Standard Deviation Standard Deviation Mean Squared Error: Skewness (Taguchi Loss Function) Kurtosis Skewness Range Kurtosis IQR (75-25) Range Span (95-5) IQR (75-25) Pp Non-Normal Span (95-5) Ppu Capability Actual DPM: Ppl Indices and (defects per million) Ppk Actual DPM Calculated DPM : Cpm (defects per million assuming %Pp (Percentile Pp) require a normal distribution) %Ppu (Percentile Ppu) minimum of %Ppl (Percentile Ppl) 10,000 %Ppk (Percentile Ppk) replications.

- 23. Case Study: Robust New Product Design - Optimizing Shutoff Valve Spring Force This is an example of DiscoverSim stochastic optimization for robust new product design, adapted from: ’ü¼ Sleeper, Andrew (2006), Design for Six Sigma Statistics: 59 Tools for Diagnosing and Solving Problems in DFSS Initiatives, NY, McGraw-Hill, pp. 782-789. ’ü¼ Sleeper, Andrew, ŌĆ£Accelerating Product Development with Simulation and Stochastic OptimizationŌĆØ, http://www.successfulstatistics.com/ ’ü¼ This example is used with permission of the author. 23

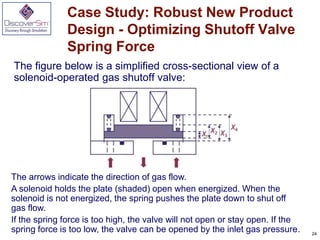

- 24. Case Study: Robust New Product Design - Optimizing Shutoff Valve Spring Force The figure below is a simplified cross-sectional view of a solenoid-operated gas shutoff valve: The arrows indicate the direction of gas flow. A solenoid holds the plate (shaded) open when energized. When the solenoid is not energized, the spring pushes the plate down to shut off gas flow. If the spring force is too high, the valve will not open or stay open. If the spring force is too low, the valve can be opened by the inlet gas pressure. 24

- 25. Optimizing Shutoff Valve Spring Force The method of specifying and testing the spring is shown below: The spring force requirement is 22 +/- 2 Newtons. The spring force equation, or Y = f(X) transfer function, is calculated as follows: Spring Length, L = -X1 + X2 - X3 + X4 Spring Rate, R = (X8 - X7)/X6 Spring Force, Y = X7 + R * (X5 - L) 25

- 26. Case Study: Catapult Variation Reduction This is an example of DiscoverSim stochastic optimization for catapult distance variation reduction, adapted from: ’ü¼ John O'Neill, Sigma Quality Management, www.sixsigmanagement.com. ’ü¼ This example is used with permission of the author. kx2 y’ĆĮ sin ’ü▒ cos ’ü▒ mg 26

- 27. Recommended Reading 1. Savage, Sam (2009), The Flaw of Averages: Why We Underestimate Risk in the Face of Uncertainty, Hoboken, NJ, Wiley. 2. Sleeper, Andrew (2006), Design for Six Sigma Statistics: 59 Tools for Diagnosing and Solving Problems in DFSS Initiatives, NY, McGraw-Hill. 27

- 28. Robust Design and Variation Reduction Using DiscoverSimŌäó Questions?