Rocky transformer technology

- 1. Rocky Transformer Sand Crusher Presentation Created by Vincent Rocco

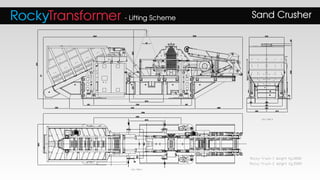

- 2. RockyTransformer - Lifting Scheme Sand Crusher

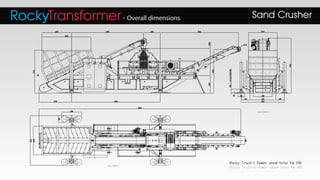

- 3. RockyTransformer- Overall dimensions Sand Crusher

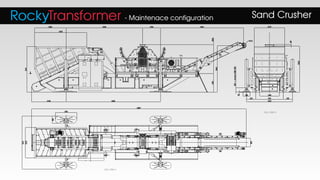

- 4. RockyTransformer - Maintenace configuration Sand Crusher

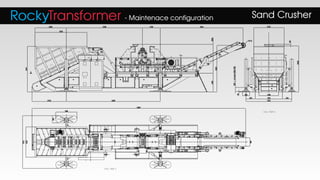

- 5. RockyTransformer - Maintenace configuration Sand Crusher

- 6. How It Works OUTPUT - Single Pass (ASTM C - 33%) 85 - 100% USEABLE SAND ROCKY TRANSFORMER EHSI SAND CRUSHER 1 - 3/8ŌĆØ Minus Feed Size FEED MATERIAL Crusher By-Product/ Sized Material

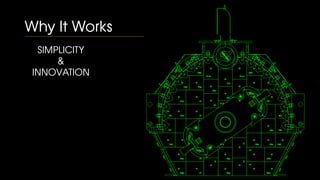

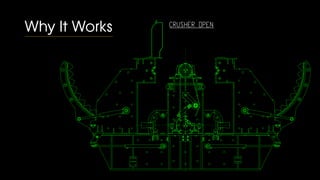

- 8. Why It Works

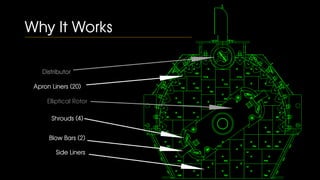

- 9. Why It Works Distributor Apron Liners (20) Blow Bars (2) Elliptical Rotor Side Liners Shrouds (4)

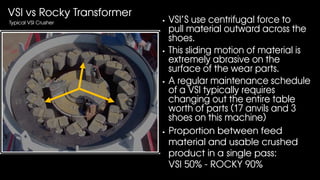

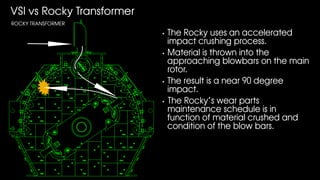

- 10. VSI vs Rocky Transformer Typical VSI Crusher VSIŌĆÖS use centrifugal force to pull material outward across the shoes. This sliding motion of material is extremely abrasive on the surface of the wear parts. A regular maintenance schedule of a VSI typically requires changing out the entire table worth of parts (17 anvils and 3 shoes on this machine) Proportion between feed material and usable crushed product in a single pass: VSI 50% - ROCKY 90%

- 11. VSI vs Rocky Transformer The Rocky uses an accelerated impact crushing process. Material is thrown into the approaching blowbars on the main rotor. The result is a near 90 degree impact. The RockyŌĆÖs wear parts maintenance schedule is in function of material crushed and condition of the blow bars. ROCKY TRANSFORMER

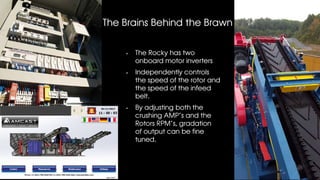

- 12. The Brains Behind the Brawn The Rocky has two onboard motor inverters Independently controls the speed of the rotor and the speed of the infeed belt. By adjusting both the crushing AMPŌĆÖs and the Rotors RPMŌĆÖs, gradation of output can be fine tuned.

- 13. High Efficiency Easy Maintenance Low Operating Costs Longer Wear Life of Parts Highlights

- 14. Rocky Sample Gradations Colorado Sample 3 /8 " minus feed Postt CCrush Alluvial Deposit 780 RPM 800 RPM 850 RPM Sieve % Passing %Passing % Passing% Passing 1/4" 100.00 - - - #4 91.00 99.60 99.70 100.00 #8 42.00 90.40 93.60 98.40 #16 11.00 63.80 70.30 87.40 #30 - 39.00 44.40 63.20 #50 - 22.20 25.50 37.40 #100 - 11.80 13.50 19.40 #200 0.10 5.80 590 8.00

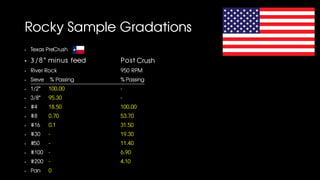

- 15. Rocky Sample Gradations Texas Pre-Crush 3 /8 " minus feed Post Crush River Rock 950 RPM Sieve % Passing % Passing 1/2" 100.00 - 3/8" 95.30 - #4 18.50 100.00 #8 0.70 53.70 #16 0.1 31.50 #30 - 19.30 #50 - 11.40 #100 - 6.90 #200 - 4.10 Pan 0

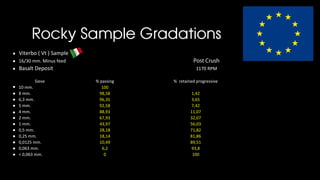

- 16. ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ Basalt Deposit 1170 RPM Sieve 10 mm. Rocky Sample Gradations Viterbo ( Vt ) Sample 16/30 mm. Minus feed Post Crush % passing 100 98,58 1,42 3,65 7,42 11,07 96,35 92,58 88,93 67,93 8 mm. 6,3 mm. 5 mm. 4 mm. 2 mm. 1 mm. 0 0,5 mm. 0,25 mm. 0,0125 mm. 0,063 mm. < 0,063 mm. 43,97 28,18 18,14 10,49 6,2 100 % retained progressive 32,07 56,03 71,82 81,86 89,51 93,8 ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ

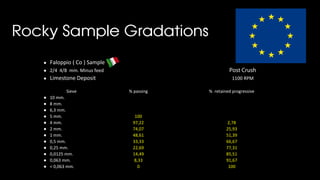

- 17. ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ ŌŚÅ 8 mm. Faloppio ( Co ) Sample 2/4 4/8 mm. Minus feed Post Crush Limestone Deposit 1100 RPM Sieve % passing % retained progressive 10 mm. 6,3 mm. 5 mm. 100 4 mm. 97,22 2,78 2 mm. 74,07 25,93 1 mm. 48,61 51,39 0,5 mm. 33,33 66,67 0,25 mm. 22,69 77,31 0,0125 mm. 14,49 85,51 0,063 mm. 8,33 91,67 < 0,063 mm. 0 100 Rocky Sample Gradations

- 18. INNOVATION IN AGGREGATE SYSTEMS.www.amcastonline.com CAPITAL EQUIPMENT DIVISION