Roof supports in coal mines

- 1. ROOF SUPPORT IN UNDERGROUND COAL MINES

- 2. CONTENTS ⊠INTRODUCTION ⊠NEED FOR SUPPORT ⊠TYPES OF SUPPORT ⊠STANDING SUPPORT ⊠INTRINSIC SUPPORT ⊠CASE STUDY ⊠REFERENCES

- 3. INTRODUCTION ⊠Every underground mine can be subjected to roof failure. ⊠It has been the major cause for fatalities to mine workers across the world. ⊠Therefore, roof supports are used to stabilize the roof. ⊠Roof supports include both intrinsic supports, such as roof bolts, and standing supports, such as timber. ⊠They interact with the ground to create a stable rock structure.

- 4. WHY ARE SUPPORTS NEEDED? ⊠To prevent major collapses of mine roof. ⊠To protect miners from small rock falls that can occur from the immediate roof skin. ⊠To prevent deformation of mine openings for access, escape and ventilation of mine workings. ⊠To safeguard expensive machines used in mines.

- 5. TYPES OF SUPPORT ⊠Intrinsic support âThe supporting system in which the elements are installed within the roof. e.g. â roof bolt, cable bolts, metal pins etc. ⊠Standing support âThe supporting system in which the elements are installed between the roof and floor. e.g. â wooden logs, metal rods, steel arches etc.

- 6. STANDING SUPPORT ⊠TIMBER SUPPORTS ⊠METAL SUPPORTS ⊠POWERED SUPPORTS ⊠STEEL ARCHES

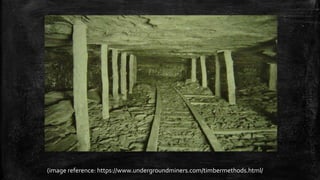

- 7. TIMBER SUPPORTS ⊠Timber supports are very common in Indian coal mines as it is cheap and easily available. ⊠Over 90% of underground coal output comes from timber supported workings. ⊠The kind of wood used as support in Indian coal mines are sal wood, teak wood, sankhon wood etc. ⊠Timber supports can be:Timber Props,Timber Bars and Wooden chocks

- 8. TIMBER PROPS ⊠The timber prop is strongest when the load acts parallel to its length. ⊠In flat seams the prop is erected vertical, and in vertical seams, the axis of the prop should be normal to the dip of the seam.

- 10. TIMBER BARS ⊠Bars act as beams. ⊠If the sides are weak, the bar is placed on vertical props. ⊠The bar should always be tight against the roof and should offer maximum area of contact against it. ⊠The side of the bar towards the roof is chopped flat for this purpose.

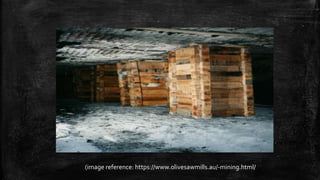

- 12. WOODEN CHOCKS ⊠A chock, cog or chockmate is a combination of sleepers above one another in a criss-cross manner. ⊠It supports a much larger stretch than a prop and is used in places where the roof is bad over a wide area and needs a substantial support. ⊠They are also erected where main roadways have to pass through area having coal pillars of inadequate size.

- 14. PROS AND CONS OF TIMBER SUPPORTS ⊠Advantages: ï They are relatively cheaper. ï They are easily available. ï They can be cut easily into desired length. ï They give early warnings when they swallow. ⊠Disadvantages: ï The resistance offered by timber is not uniform. Hence, it is difficult to standardise the design of support system. ï They may have inherent defects which will reduce the load bearing capacity considerably. ï The yield of timber is relatively low.

- 15. METAL SUPPORTS ⊠Iron and steel have been used in mines in the form of rigid and yielding props, beams and girders, reinforcement in concrete and corrugated sheets. ⊠FRICTION PROPS ⊠HYDRAULIC PROPS ⊠POWERED SUPPORTS ⊠STEEL BARS

- 16. FRICTION PROPS ⊠They are early bearing props and accept the roof and load very quickly. ⊠They have constant load yield characteristics. ⊠Friction props were adopted on longwall face with sand stowing first time in Chinakuri colliery.

- 18. HYDRAULIC PROPS ⊠A hydraulic prop is simply a hydraulic jack. ⊠They have been used at longwall mechanised faces in our country. ⊠A hydraulic prop can be set to take immediately 3/4th of the maximum load but when overloaded it will yield at the designed load after which the resistance is uniform.

- 20. PROS AND CONS OF METAL SUPPORTS ⊠Advantages: ïThey can be easily re-used. ïThey have high load carrying capacity. ⊠Disadvantages: ïThey are relatively more expensive than timber supports. ïThey do not give early warning signs as timber. ïThey can get corroded due to moisture and mine water.

- 21. ⊠Powered supports enables the cutting machine to be used in full capacity as they can be moved forward fast enough to keep pace with any modern face cutter. ⊠Thus, they enable rapid advance of the face which in turn brings about improvement in roof conditions at the face. POWERED SUPPORT

- 22. SELF â ADVANCING OR WALKING SUPPORT ⊠These are open circuit type hydraulic chocks which, when already erected at a place, can be retracted by hydraulic pressure, pushed to the new site of erection by hydraulic shifting cylinders and erected by hydraulic pressure ⊠A workman is not required to handle the supports during any of its processes, except for guiding the roof bars supported by the hydraulic props. ⊠The self-advancing supports are used in coal mines on prop-free front of longwall faces and were introduced first time in India in Moonidih colliery, BCCL.

- 24. SHIELD SUPPORT ⊠The shield supports provides a continuous cover all along the face by canopies placed side by side. ⊠It is like a multi-leg hydraulic chock support except for a little difference in construction at the rear side, i.e., goaf side. ⊠The shield supports are with four legs which react directly with the canopy. ⊠It is suitable for sub-level caving in thick seams or for conventional operations in longwall faces.

- 26. STEEL ARCHES ⊠They are used for supporting permanent and semi-permanent roadways. ⊠Heavy section rails in two parts are suitably shaped to form an inverted U when assembled together. ⊠They have no yielding property. ⊠To keep arches in contact with the roof and sides wooden laggings are placed on top and sides.

- 28. INTRINSIC SUPPORT ⊠ROOF BOLTING ⊠ROOF STITCHING ⊠WOODEN DOWEL ⊠BAMBOO BOLTING

- 29. ROOF BOLTING ⊠Roof bolting is the practice of drilling vertical holes in the roof and fixing steel bolts into the in a manner that the bolts grip the strata and support the immediate roof. ⊠The bolted roof strata behave as one thick seam capable of supporting not only their own weight ut the weight of the strata above them. ⊠They are of two types: 1) Slot and wedge 2) Expansion shell

- 31. PROS AND CONS OF ROOF BOLTING ïAdvantages: ⊠It is simple to apply, easy to mechanise and moderately cheap in cost. ⊠It gives greater headroom and clearance in the roadway. ⊠Storage space required is small. ïDisadvantages: ⊠It can not be applied in all cases. ⊠It gives no warning signs of impending failure. ⊠Some types of bolts are not recoverable. e.g. slot and wedge bolt

- 32. ROOF STITCHING ⊠The principle of roof stitching is the same as that for roof bolting, i.e., the immediate rocks are held together as a composite stratum of large thickness. ⊠Roof stitching was adopted in coal mines as well as metal mines at Balaghat and Seetharama mica mine. It cannot be used in mines where roof condition deteriorates immediately after blasting. ⊠This method of support is both effective and cheap.

- 34. CASE STUDY OF TANDSI MINE, WCL ⊠Rock Mass Rating(RMR) = 44-64 ⊠Roof was supported by roof bolts up to 1.5 m length ⊠Gallery width = 4.5 m ⊠The roof bolts were installed such that there were 3 bolts in each row. ⊠The bolts had a spacing of 1.5 m from each other and 0.75 m from the pillar. ⊠One of the bolts was drilled vertically. And the other two were drilled inclined in such a way that they went into the pillar there by supporting the overburden pressure.

- 35. Design of layout for roof bolting (image reference: Sudipta Mukhopadhya and Satish Sharma (2017), A case study illustration of the layout and support in an Indian coal mine.)

- 36. REFERENCES 1. D.J. Deshmukh, Rock Mechanics and Roof Supports. Elements of MiningTechnologyVol.1. 2. R.D. Singh, Strata Control in Coal Mines. Principles and Practices of Modern Coal Mining. 3. Christopher Mark andThomas M. Barczak, Fundamentals ofCoal Mine Roof Support. 4. https://www.kau.edu.sa/, Mine Support. 5. Manoj Kumar Biswal, Design of Support System for Bord and Pillar Workings. 6. https://www.stolajohannes.cz/, Mine Supports. 7. https://www.cdc,gov/, Roof Support.