Rootcellar design, Steve Belyea & Jim Merkel

Download as ppt, pdf1 like1,705 views

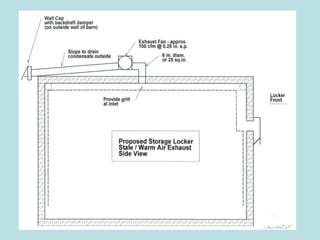

This document discusses various methods and considerations for designing and maintaining root cellars for food storage. It provides examples of different root cellar designs used by individuals and farms. It also covers the ideal storage conditions for different crops and factors involved in effectively controlling the storage environment, such as insulation, ventilation, humidity and temperature regulation. Sizing examples are given for storage units and cooling/ventilation systems.

1 of 66

Download to read offline

Ad

Recommended

Kristech oven-catalog

Kristech oven-catalogShailesh Gesota

╠²

The document describes various tray drying ovens and their applications in industries such as rubber, plastic, and food processing. It details specifications, construction materials, heating methods, and control systems, while offering customization options for size, tray types, and temperature settings. Additionally, it provides contact information for Kristech Automation for further inquiries and product offerings.DC Inverter Aircon with EVI and ERV technology

DC Inverter Aircon with EVI and ERV technologyJohnWang254

╠²

The document discusses a new energy recovery ventilator (ERV) system that improves indoor air quality by combining dehumidification, air purification, and air conditioning technologies. It highlights the system's ability to maintain fresh and healthy air in various environmental conditions, emphasizing energy efficiency through advanced features like DC inverter technology and enhanced vapor injection. The ERV can optimize temperature control while being suitable for a wide range of applications in commercial, educational, and residential buildings.Blfreshbox100wifileaflet201806en

Blfreshbox100wifileaflet201806enOliverh Kalprit

╠²

The document describes the Freshbox 100 WiFi single-room air handling unit, which provides efficient supply and exhaust ventilation with options for electric pre-heating and re-heating, making it suitable for various climates. It features advanced EC motors for high energy efficiency, built-in air purification filters, and remote control via Wi-Fi. Additionally, it includes heat recovery capabilities to minimize energy loss while maintaining indoor air quality.Cem 350 hvac ductwork ii 11 2015

Cem 350 hvac ductwork ii 11 2015miresmaeil

╠²

The document discusses issues with HVAC ductwork systems installed in attics. Key points include:

1) Ductwork installed in attics can lead to condensation problems and reduced insulation effectiveness due to temperature differences between the attic and interior spaces.

2) Accessing HVAC equipment for maintenance like filter changes can be difficult when installed in attics.

3) Installing ductwork and air handlers in attics leads to increased heating and cooling losses compared to keeping them within the insulated building envelope. This requires oversizing equipment and increases energy costs.5 Chea Group3

5 Chea Group35CHEAGroup3A

╠²

The document discusses three chemical engineering problems involving heat exchanger design and optimization. Problem 3 involves determining the optimum insulation thickness for a steam pipe. Problem 9 involves determining the cooling water flow rate and exit temperature for a condenser. Problem 15 involves determining the optimum exit temperature of cooling water and length of tubes for an air cooler.Step 4 - Properly Sized, Designed, Installed, and Commissioned HVAC Systems

Step 4 - Properly Sized, Designed, Installed, and Commissioned HVAC SystemsSynergy Airflow and Ventilation

╠²

This document outlines the importance of properly sized, designed, installed, and commissioned HVAC systems in energy-efficient homes, highlighting that many new constructions overlook these critical aspects, leading to comfort and efficiency issues. It emphasizes the need for comprehensive manual calculations (J, S, D, and T) to ensure HVAC systems work correctly with modern building practices and stresses the need for ongoing education and adherence to best practices within the HVAC industry. The document seeks to address common misconceptions and promote a holistic approach to HVAC and building science for improved indoor air quality and energy efficiency.Kemampuan Sarana Produksi dan Teknologi Industri Besi dan Baja

Kemampuan Sarana Produksi dan Teknologi Industri Besi dan BajaDewan Nasional Perubahan Iklim

╠²

The document summarizes the facilities, products, and technologies of Gunung Group's iron and steel industry in Indonesia. It describes the group's production facilities including blast furnaces, continuous casters, hot rolling mills, plate mills, and other equipment. It also discusses the group's strategies to support mega infrastructure projects through quality management systems and environmental technologies. Some challenges for the domestic steel industry are mentioned regarding raw materials, domestic market competition, and policies. Opportunities and hopes for developing the national steel industry are improving infrastructure and cooperation with research institutions.Tiny House presintation dalton goodwin

Tiny House presintation dalton goodwinDalton Goodwin

╠²

This document describes the layout and features of a 481 square foot tiny house, including a 38 square foot bathroom, 149 square foot bedroom, and multi-functioning living room. Storage options include stair storage, open shelves in all rooms, kitchen cabinets, and bathroom cabinets. Energy and utilities are provided by 800 watt solar panels, an instantaneous water heater, composting toilet, wood burning stove for heat and cooking, and greywater filtration system.Presentation finland

Presentation finlandKallele

╠²

This document discusses climate control in Finnish pig farms. It outlines that pigs can survive without feed for 3 weeks, water for 3 days, and air for 3 minutes, demonstrating the importance of proper climate control. The document then discusses ventilation principles, potential issues like rooms being too cold, warm, or drafty. It also addresses air quality factors and control options. Finally, it recommends different air inlet systems for different pig age groups and stresses the importance of proper system design, calculations, drawings and settings for effective climate control.Design of a Food Dehydrator

Design of a Food DehydratorDoruk Angun

╠²

This document describes the design of an apple dehydrator. It includes sections on the instruments used, which are an AC fan, heater, stainless steel trays, steel sheet housing, and thermostat. The design criteria aimed for the dehydrator to be low cost, small, efficient, and quick drying. Technical drawings and diagrams show the dehydrator layout. Cost analysis found the total cost to be $95.79. The results and conclusion sections discuss using mass and energy balances to model the drying performance for different air flow rates.How to obtain a high Tomato yield - Ep Heuvelink

How to obtain a high Tomato yield - Ep HeuvelinkGreen Smile

╠²

This document discusses how to obtain high tomato yields of 100 kg per m2 or more per year. It identifies several key factors for high yields: 1) Modern greenhouse technology that provides high light transmission, precise climate control, and semi-closed structures; 2) Advanced cultivation techniques like high wire systems and grafting that allow year-round production; and 3) High-yielding tomato cultivars developed through breeding. It also examines specific techniques like using diffuse light, precise temperature and humidity control, and supplemental CO2 that optimize growing conditions for photosynthesis and fruit production. The document concludes that combining state-of-the-art greenhouses, cultivation methods, and tomato varieties has allowed yields to increase dramatically in recent decades.Ventoergoa251proen

Ventoergoa251proenOliverh Kalprit

╠²

The document provides a detailed overview of the Vento Ergo A25-1 single-room ventilation units, highlighting their energy-efficient features like heat recovery of up to 85% and customizable humidity control. It describes the design and technical specifications, including the ceramic energy accumulator, installation options, and operation modes for efficient air exchange. Additionally, the document outlines the provided accessories and mounting kits for various wall thicknesses.2345 project

2345 projectEthan Ehrman

╠²

This document summarizes a heat load analysis conducted on an apartment. The team measured the apartment dimensions, wall constructions, and window/door properties to calculate heat loss through transmission and infiltration. They determined the existing furnace was oversized for the calculated heat load of 10,189 BTU/HR. To save 10% on heating costs, they proposed reducing the heat load by over 1,000 BTU/HR through lowering the indoor temperature, installing more insulated windows, and improving air sealing. However, the $1,396 cost of these upgrades would not be recouped for over 75 years, so were not deemed worthwhile.HVAC Case Study

HVAC Case StudyNate Lee

╠²

The document analyzes the best HVAC system for a retail store called Discount Dan's located in Biloxi, Mississippi. It recommends a heat pump, split duct, single zone, constant volume system because it has low initial and operating costs, requires minimal maintenance, and would not cause the store to close if one component failed. The system was chosen because heat pumps are efficient, do not require gas lines, and could provide both heating and cooling for the store given its mild climate. Three COP 3 heat pump units with air handlers would meet the heating and cooling needs of the 15,000 square foot store.BioFire Fireplaces: Features and how it is built

BioFire Fireplaces: Features and how it is builtAlex W├Črz

╠²

BioFire fireplaces provide 12-24 hours of warmth from one fire due to their heavy ceramic refractory brick construction that absorbs heat during combustion and slowly radiates it afterwards. They have the highest burning temperature of 1000┬░C for complete combustion and very low emissions. Radiant heat from the surface is gentle, comfortable heating without drying the air or causing much dust movement, making them suitable for allergy and asthma sufferers. Each BioFire is custom designed and engineered to maximize efficiency.Natural and Mechanical Cooling- Kirk Edit 021715

Natural and Mechanical Cooling- Kirk Edit 021715Kirk Jones

╠²

This document discusses natural and mechanical cooling methods for farm and homestead storage. It begins by describing traditional natural cooling techniques like underground storage, spring water, and ice houses. It then outlines different mechanical cooling systems like venting, fans, refrigeration, and controllers. The document provides examples of different cooling solutions for various storage needs like root cellars, walk-in coolers, and markets. It also discusses important post-harvest care and techniques to remove field heat from produce before storage. Overall, the document provides an overview of both natural and mechanical cooling options and considerations for choosing the right system based on storage needs and scale.Iivr rtp

Iivr rtpRamabhau Patil

╠²

This document discusses hybrid cold chain solutions for preservation of fruits and vegetables in India. It begins by noting that India is the second largest producer of fruits and vegetables globally but also experiences significant post-harvest losses of 3-18% due to lack of cold storage and processing infrastructure. It then outlines various components of an integrated cold chain including pre-cooling, cold storage, distribution and marketing. Specific low-cost solutions are presented, such as mobile cool chambers, evaporative cooled storage structures, and earth tubes for cooling. Examples of farmers using these solutions are also provided. The document emphasizes that growing processable varieties and providing low-cost cool storage is key to increasing processing levels and reducing post-harvest losses in India.Hybrid cool chain for preservation of fruits & vegetables in india

Hybrid cool chain for preservation of fruits & vegetables in indiaRamabhau Patil

╠²

The document discusses India's production and post-harvest scenario for fruits and vegetables. It notes that agriculture contributes 16% of GDP but post-harvest losses amount to Rs. 45,000 crores annually due to lack of processing and perishability. Various low-cost cooling methods and storage structures are presented, including mobile cool chambers costing Rs. 18,000-20,000, evaporatively cooled rooms that increase shelf life, and earth tubes that use constant underground temperatures for passive heating and cooling. Case studies show farmers successfully using evaporative cooled rooms costing Rs. 75,000 for short-term on-farm storage. The document emphasizes growing processable varieties and providing low-cost cool storage to increase processing and reduce lossesCold Chain Management

Cold Chain ManagementRamabhau Patil

╠²

This document discusses India's production and post-harvest scenario for perishable goods and the need for cold chain management. It notes that India is a major producer of fruits and vegetables but suffers significant post-harvest losses of 3-18% due to lack of cold storage and processing. It then outlines various components of an integrated cold chain including pre-cooling, cold storage, distribution, and marketing. Specific technologies are described that can help reduce losses for small-scale farmers such as mobile cooling chambers, evaporative cooled storage structures, and earth tubes for cooling. Benefits of cooling produce and its effects on storage life are also summarized.MAINTAINING QUALITYPOSTHARVEST KITS AND REFERIGERATION FOR BERRIES

MAINTAINING QUALITYPOSTHARVEST KITS AND REFERIGERATION FOR BERRIESMark Klingman

╠²

This document provides information on maintaining quality and refrigeration for berries during postharvest handling. It emphasizes the importance of rapid cooling through a "cold chain" from field to consumer to extend shelf life. Proper harvesting, packaging, cooling, storage and transportation are discussed to minimize weight loss, decay and quality declines in berries. Mobile and DIY refrigeration options are presented for small farms.Storage system and management for horticultural crops

Storage system and management for horticultural cropsMaizatulIbrahim2

╠²

Storage system for horticultural cropUnit 9. Storage of Ecological Vegetables after Harvesting

Unit 9. Storage of Ecological Vegetables after HarvestingKarel Van Isacker

╠²

This document provides information on proper storage methods for ecological vegetables after harvesting. It discusses the importance of temperature, relative humidity, atmospheric composition, and light control in storage. Specific storage techniques covered include refrigeration, controlled and modified atmospheres, and freezing. The goals of storage are to slow biological and microbial activity while preserving quality and reducing moisture loss. Proper harvesting, packaging, and use of a cold chain during transportation are also emphasized for maintaining freshness.12667-1999.pptx

12667-1999.pptxglshtplu1

╠²

The document discusses the design considerations for cold storage rooms to preserve perishable products, with emphasis on refrigeration systems and cooling load calculation. It outlines the various heat gain sources, such as transmission, infiltration, product, internal, and refrigeration equipment heat loads, which must be accounted for in the refrigeration system design. Additionally, it provides guidelines on insulation types and thicknesses, factors influencing heat transfer, and examples for calculating total refrigeration load.Cooling Load Calculations and vapour compression

Cooling Load Calculations and vapour compressionBalaVenki1

╠²

The document provides a comprehensive overview of cooling load estimation for refrigeration systems, detailing factors that contribute to heat gain such as outside heat, air changes, and product cooling loads. It includes equations for calculating various heat loads, examples of practical applications, and data tables to ensure accurate load assessments. Additionally, it emphasizes the importance of accounting for defrosting needs and other operational considerations when determining equipment capacity.METHODS OF STORAGE AND POST HARVEST DISORDERS OF FRUIT CROPS

METHODS OF STORAGE AND POST HARVEST DISORDERS OF FRUIT CROPSAmanDohre

╠²

This document summarizes methods of storage and post-harvest disorders of fruit crops. It discusses the need for storage to preserve fruits and vegetables by slowing biological activity and reducing moisture loss, damage, and pathogens. Traditional low-cost storage methods include in-situ storage, storage using sand and coir, storage in pits, and storage using evaporative coolers. High-cost improved storage methods include cold storage, controlled atmosphere storage, modified atmosphere storage, solar-driven cold stores, and hypobaric/low pressure storage. Controlled atmosphere storage aims to reduce respiration and microbial growth by manipulating oxygen and carbon dioxide levels specific to each fruit.More Related Content

What's hot (7)

Presentation finland

Presentation finlandKallele

╠²

This document discusses climate control in Finnish pig farms. It outlines that pigs can survive without feed for 3 weeks, water for 3 days, and air for 3 minutes, demonstrating the importance of proper climate control. The document then discusses ventilation principles, potential issues like rooms being too cold, warm, or drafty. It also addresses air quality factors and control options. Finally, it recommends different air inlet systems for different pig age groups and stresses the importance of proper system design, calculations, drawings and settings for effective climate control.Design of a Food Dehydrator

Design of a Food DehydratorDoruk Angun

╠²

This document describes the design of an apple dehydrator. It includes sections on the instruments used, which are an AC fan, heater, stainless steel trays, steel sheet housing, and thermostat. The design criteria aimed for the dehydrator to be low cost, small, efficient, and quick drying. Technical drawings and diagrams show the dehydrator layout. Cost analysis found the total cost to be $95.79. The results and conclusion sections discuss using mass and energy balances to model the drying performance for different air flow rates.How to obtain a high Tomato yield - Ep Heuvelink

How to obtain a high Tomato yield - Ep HeuvelinkGreen Smile

╠²

This document discusses how to obtain high tomato yields of 100 kg per m2 or more per year. It identifies several key factors for high yields: 1) Modern greenhouse technology that provides high light transmission, precise climate control, and semi-closed structures; 2) Advanced cultivation techniques like high wire systems and grafting that allow year-round production; and 3) High-yielding tomato cultivars developed through breeding. It also examines specific techniques like using diffuse light, precise temperature and humidity control, and supplemental CO2 that optimize growing conditions for photosynthesis and fruit production. The document concludes that combining state-of-the-art greenhouses, cultivation methods, and tomato varieties has allowed yields to increase dramatically in recent decades.Ventoergoa251proen

Ventoergoa251proenOliverh Kalprit

╠²

The document provides a detailed overview of the Vento Ergo A25-1 single-room ventilation units, highlighting their energy-efficient features like heat recovery of up to 85% and customizable humidity control. It describes the design and technical specifications, including the ceramic energy accumulator, installation options, and operation modes for efficient air exchange. Additionally, the document outlines the provided accessories and mounting kits for various wall thicknesses.2345 project

2345 projectEthan Ehrman

╠²

This document summarizes a heat load analysis conducted on an apartment. The team measured the apartment dimensions, wall constructions, and window/door properties to calculate heat loss through transmission and infiltration. They determined the existing furnace was oversized for the calculated heat load of 10,189 BTU/HR. To save 10% on heating costs, they proposed reducing the heat load by over 1,000 BTU/HR through lowering the indoor temperature, installing more insulated windows, and improving air sealing. However, the $1,396 cost of these upgrades would not be recouped for over 75 years, so were not deemed worthwhile.HVAC Case Study

HVAC Case StudyNate Lee

╠²

The document analyzes the best HVAC system for a retail store called Discount Dan's located in Biloxi, Mississippi. It recommends a heat pump, split duct, single zone, constant volume system because it has low initial and operating costs, requires minimal maintenance, and would not cause the store to close if one component failed. The system was chosen because heat pumps are efficient, do not require gas lines, and could provide both heating and cooling for the store given its mild climate. Three COP 3 heat pump units with air handlers would meet the heating and cooling needs of the 15,000 square foot store.BioFire Fireplaces: Features and how it is built

BioFire Fireplaces: Features and how it is builtAlex W├Črz

╠²

BioFire fireplaces provide 12-24 hours of warmth from one fire due to their heavy ceramic refractory brick construction that absorbs heat during combustion and slowly radiates it afterwards. They have the highest burning temperature of 1000┬░C for complete combustion and very low emissions. Radiant heat from the surface is gentle, comfortable heating without drying the air or causing much dust movement, making them suitable for allergy and asthma sufferers. Each BioFire is custom designed and engineered to maximize efficiency.Similar to Rootcellar design, Steve Belyea & Jim Merkel (20)

Natural and Mechanical Cooling- Kirk Edit 021715

Natural and Mechanical Cooling- Kirk Edit 021715Kirk Jones

╠²

This document discusses natural and mechanical cooling methods for farm and homestead storage. It begins by describing traditional natural cooling techniques like underground storage, spring water, and ice houses. It then outlines different mechanical cooling systems like venting, fans, refrigeration, and controllers. The document provides examples of different cooling solutions for various storage needs like root cellars, walk-in coolers, and markets. It also discusses important post-harvest care and techniques to remove field heat from produce before storage. Overall, the document provides an overview of both natural and mechanical cooling options and considerations for choosing the right system based on storage needs and scale.Iivr rtp

Iivr rtpRamabhau Patil

╠²

This document discusses hybrid cold chain solutions for preservation of fruits and vegetables in India. It begins by noting that India is the second largest producer of fruits and vegetables globally but also experiences significant post-harvest losses of 3-18% due to lack of cold storage and processing infrastructure. It then outlines various components of an integrated cold chain including pre-cooling, cold storage, distribution and marketing. Specific low-cost solutions are presented, such as mobile cool chambers, evaporative cooled storage structures, and earth tubes for cooling. Examples of farmers using these solutions are also provided. The document emphasizes that growing processable varieties and providing low-cost cool storage is key to increasing processing levels and reducing post-harvest losses in India.Hybrid cool chain for preservation of fruits & vegetables in india

Hybrid cool chain for preservation of fruits & vegetables in indiaRamabhau Patil

╠²

The document discusses India's production and post-harvest scenario for fruits and vegetables. It notes that agriculture contributes 16% of GDP but post-harvest losses amount to Rs. 45,000 crores annually due to lack of processing and perishability. Various low-cost cooling methods and storage structures are presented, including mobile cool chambers costing Rs. 18,000-20,000, evaporatively cooled rooms that increase shelf life, and earth tubes that use constant underground temperatures for passive heating and cooling. Case studies show farmers successfully using evaporative cooled rooms costing Rs. 75,000 for short-term on-farm storage. The document emphasizes growing processable varieties and providing low-cost cool storage to increase processing and reduce lossesCold Chain Management

Cold Chain ManagementRamabhau Patil

╠²

This document discusses India's production and post-harvest scenario for perishable goods and the need for cold chain management. It notes that India is a major producer of fruits and vegetables but suffers significant post-harvest losses of 3-18% due to lack of cold storage and processing. It then outlines various components of an integrated cold chain including pre-cooling, cold storage, distribution, and marketing. Specific technologies are described that can help reduce losses for small-scale farmers such as mobile cooling chambers, evaporative cooled storage structures, and earth tubes for cooling. Benefits of cooling produce and its effects on storage life are also summarized.MAINTAINING QUALITYPOSTHARVEST KITS AND REFERIGERATION FOR BERRIES

MAINTAINING QUALITYPOSTHARVEST KITS AND REFERIGERATION FOR BERRIESMark Klingman

╠²

This document provides information on maintaining quality and refrigeration for berries during postharvest handling. It emphasizes the importance of rapid cooling through a "cold chain" from field to consumer to extend shelf life. Proper harvesting, packaging, cooling, storage and transportation are discussed to minimize weight loss, decay and quality declines in berries. Mobile and DIY refrigeration options are presented for small farms.Storage system and management for horticultural crops

Storage system and management for horticultural cropsMaizatulIbrahim2

╠²

Storage system for horticultural cropUnit 9. Storage of Ecological Vegetables after Harvesting

Unit 9. Storage of Ecological Vegetables after HarvestingKarel Van Isacker

╠²

This document provides information on proper storage methods for ecological vegetables after harvesting. It discusses the importance of temperature, relative humidity, atmospheric composition, and light control in storage. Specific storage techniques covered include refrigeration, controlled and modified atmospheres, and freezing. The goals of storage are to slow biological and microbial activity while preserving quality and reducing moisture loss. Proper harvesting, packaging, and use of a cold chain during transportation are also emphasized for maintaining freshness.12667-1999.pptx

12667-1999.pptxglshtplu1

╠²

The document discusses the design considerations for cold storage rooms to preserve perishable products, with emphasis on refrigeration systems and cooling load calculation. It outlines the various heat gain sources, such as transmission, infiltration, product, internal, and refrigeration equipment heat loads, which must be accounted for in the refrigeration system design. Additionally, it provides guidelines on insulation types and thicknesses, factors influencing heat transfer, and examples for calculating total refrigeration load.Cooling Load Calculations and vapour compression

Cooling Load Calculations and vapour compressionBalaVenki1

╠²

The document provides a comprehensive overview of cooling load estimation for refrigeration systems, detailing factors that contribute to heat gain such as outside heat, air changes, and product cooling loads. It includes equations for calculating various heat loads, examples of practical applications, and data tables to ensure accurate load assessments. Additionally, it emphasizes the importance of accounting for defrosting needs and other operational considerations when determining equipment capacity.METHODS OF STORAGE AND POST HARVEST DISORDERS OF FRUIT CROPS

METHODS OF STORAGE AND POST HARVEST DISORDERS OF FRUIT CROPSAmanDohre

╠²

This document summarizes methods of storage and post-harvest disorders of fruit crops. It discusses the need for storage to preserve fruits and vegetables by slowing biological activity and reducing moisture loss, damage, and pathogens. Traditional low-cost storage methods include in-situ storage, storage using sand and coir, storage in pits, and storage using evaporative coolers. High-cost improved storage methods include cold storage, controlled atmosphere storage, modified atmosphere storage, solar-driven cold stores, and hypobaric/low pressure storage. Controlled atmosphere storage aims to reduce respiration and microbial growth by manipulating oxygen and carbon dioxide levels specific to each fruit.coldstoragepptpragati-150509061348-lva1-app6891.pdf

coldstoragepptpragati-150509061348-lva1-app6891.pdframyaas131

╠²

This document discusses the design of cold storage facilities. It covers various considerations for cold storage design including uniform temperatures, humidity, air movement, and product entry temperatures. It also outlines the key aspects of cold storage design such as site selection, building orientation, sizing calculations, insulation, and refrigeration system selection. Heat load calculations are an important part of ensuring the refrigeration system can maintain the desired environmental conditions within the cold storage.Cold storage ppt pragati

Cold storage ppt pragatiPragati Singham

╠²

The document outlines the design and considerations involved in creating a cold storage facility for perishable products, highlighting aspects such as site selection, refrigeration systems, heat load calculations, and storage space requirements. It also discusses the various types of cold storage, problems associated with refrigeration, and specific design elements necessary for optimizing performance. References to industry standards and academic sources are provided to support the information presented.coldstoragepptpragati-150509061348-lva1-app6891.pptx

coldstoragepptpragati-150509061348-lva1-app6891.pptxPrabhatHambire

╠²

This document discusses the design of cold storage facilities. It addresses considerations for cold storage design such as uniform temperatures, air movement, and humidity control. It also outlines the main components of cold storage design, which include site selection, building orientation, sizing calculations, insulation, and refrigeration systems. Heat load calculations are also an important part of cold storage design to determine the required refrigeration capacity. Software can be used to help analyze heat transfer and calculate refrigeration loads.Zero energy cool chambers for post harvest management of fruits and vegetables

Zero energy cool chambers for post harvest management of fruits and vegetablesPratibha Kashyap

╠²

This document describes a zero energy cool chamber developed by an Indian institute as a low-cost alternative to refrigeration for storing fruits and vegetables. It works using evaporative cooling principles by keeping bricks and sand in the chamber walls saturated with water. During hot summer months, it can maintain inside temperatures of 15-18┬░C and 95% relative humidity. It allows small farmers to store produce for a few days to avoid distress selling. Key advantages are that it is environmentally friendly, inexpensive to construct using local materials, and reduces post-harvest losses for farmers.CA in silo bin

CA in silo binshyamala chinnappan

╠²

Controlled atmosphere storage involves regulating oxygen, carbon dioxide, nitrogen, temperature and humidity levels to extend the shelf life of stored food products. Controlled atmosphere storage employs lower oxygen and higher carbon dioxide levels than ambient air. Controlled atmosphere storage inhibits bacterial and mould growth, protects against insects, reduces moisture loss and controls biochemical processes to slow ripening. Modern storage facilities include silos and bins of various materials and sizes. Controlled atmosphere storage can be combined with cold storage, which involves maintaining low temperatures to further extend shelf life. The design of a controlled atmosphere cold store involves considerations for insulation, refrigeration equipment, ventilation, storage chambers and maintenance procedures.Ad

Recently uploaded (20)

How payment terms are configured in Odoo 18

How payment terms are configured in Odoo 18Celine George

╠²

Payment terms in Odoo 18 help define the conditions for when invoices are due. This feature can split payments into multiple parts and automate due dates based on specific rules.LDMMIA Yoga S10 Free Workshop Grad Level

LDMMIA Yoga S10 Free Workshop Grad LevelLDM & Mia eStudios

╠²

This is complete for June 17th. For the weekend of Summer Solstice

June 20th-22nd.

6/17/25: ŌĆ£My now Grads, YouŌĆÖre doing well. I applaud your efforts to continue. We all are shifting to new paradigm realities. Its rough, thereŌĆÖs good and bad days/weeks. However, Reiki with Yoga assistance, does work.ŌĆØ

6/18/25: "For those planning the Training Program Do Welcome. Happy Summer 2k25. You are not ignored and much appreciated. Our updates are ongoing and weekly since Spring. I Hope you Enjoy the Practitioner Grad Level. There's more to come. We will also be wrapping up Level One. So I can work on Levels 2 topics. Please see documents for any news updates. Also visit our websites. Every decade I release a Campus eMap. I will work on that for summer 25. We have 2 old libraries online thats open. https://ldmchapels.weebly.com "

Our Monthly Class Roster is 7,141 for 6/21.

ALL students get privacy naturally. Thx Everyone.

As a Guest Student,

You are now upgraded to Grad Level.

See Uploads for ŌĆ£Student CheckinsŌĆØ & ŌĆ£S9ŌĆØ. Thx.

Happy Summer 25.

These are also timeless.

Thank you for attending our workshops.

If you are new, do welcome.

For visual/Video style learning see our practitioner student status.

This is listed under our new training program. Updates ongoing levels 1-3 this summer. We just started Session 1 for level 1.

These are optional programs. I also would like to redo our library ebooks about Hatha and Money Yoga. THe Money Yoga was very much energy healing without the Reiki Method. An updated ebook/course will be done this year. These Projects are for *all fans, followers, teams, and Readers. TY for being presenting.2025 June Year 9 Presentation: Subject selection.pptx

2025 June Year 9 Presentation: Subject selection.pptxmansk2

╠²

2025 June Year 9 Presentation: Subject selectionHow to Implement Least Package Removal Strategy in Odoo 18 Inventory

How to Implement Least Package Removal Strategy in Odoo 18 InventoryCeline George

╠²

In Odoo, the least package removal strategy is a feature designed to optimize inventory management by minimizing the number of packages open to fulfill the orders. This strategy is particularly useful for the business that deals with products packages in various quantities such as boxes, cartons or palettes. Communicable Diseases and National Health Programs ŌĆō Unit 9 | B.Sc Nursing 5t...

Communicable Diseases and National Health Programs ŌĆō Unit 9 | B.Sc Nursing 5t...RAKESH SAJJAN

╠²

This PowerPoint presentation covers Unit 9 ŌĆō Communicable Diseases and National Health Programs, a core part of the 5th Semester B.Sc Nursing (Community Health Nursing ŌĆō I) syllabus, as outlined by the Indian Nursing Council (INC).

This unit enables nursing students to understand the epidemiology, prevention, control, and nursing management of common communicable diseases in India, while also offering a structured overview of the National Health Programs implemented to address them.

The content is critical for effective field practice, disease surveillance, early detection, referral, and health education, equipping students to participate in public health interventions and outbreak control at community and national levels.

¤ōś Key Topics Covered in the PPT:

Definition and classification of communicable diseases

Modes of transmission and chain of infection

Common communicable diseases in India:

Malaria

Tuberculosis

Leprosy

Dengue

HIV/AIDS

Hepatitis

COVID-19 (if included in the current curriculum)

Diarrheal diseases

Acute Respiratory Infections (ARIs)

Epidemiological factors, causative agents, symptoms, and incubation periods

Prevention and control strategies: primary, secondary, and tertiary levels

Nursing responsibilities in patient care, contact tracing, community surveillance, and outbreak control

Health education and behavior change communication for community awareness

Vaccination schedules and cold chain maintenance

National Health Programs related to communicable diseases:

National Vector Borne Disease Control Program (NVBDCP)

Revised National Tuberculosis Control Program (RNTCP)

National Leprosy Eradication Program (NLEP)

National AIDS Control Program (NACP)

Universal Immunization Program (UIP)

IDSP ŌĆō Integrated Disease Surveillance Program

Overview of standard treatment protocols, referral mechanisms, and community nurseŌĆÖs role in program implementation

This presentation is ideal for:

Nursing students preparing for university exams, class tests, and field projects

Tutors teaching infectious disease nursing and public health interventions

Nurses involved in immunization, outbreak investigation, and contact tracing

It provides a student-friendly breakdown of concepts, aligned with national priorities, including flowcharts, tables, case examples, and simplified text for field-level application.LDM Recording Presents Yogi Goddess by LDMMIA

LDM Recording Presents Yogi Goddess by LDMMIALDM & Mia eStudios

╠²

A bonus dept update. Happy Summer 25 almost. Do Welcome or Welcome back. Our 10th Free workshop will be released the end of this week, June 20th Weekend. All Materials/updates/Workshops are timeless for future students.

6/17/25: ŌĆ£My now Grads, YouŌĆÖre doing well. I applaud your efforts to continue. We all are shifting to new paradigm realities. Its rough, thereŌĆÖs good and bad days/weeks. However, Reiki with Yoga assistance, does work.ŌĆØ

6/18/25: "For those planning the Training Program Do Welcome. Happy Summer 2k25. You are not ignored and much appreciated. Our updates are ongoing and weekly since Spring. I Hope you Enjoy the Practitioner Grad Level. There's more to come. We will also be wrapping up Level One. So I can work on Levels 2 topics. Please see documents for any news updates. Also visit our websites. Every decade I release a Campus eMap. I will work on that for summer 25. We have 2 old libraries online thats open. https://ldmchapels.weebly.com "

A Safe House,

sanctuary of virtual relaxation and rejuvenation.

By ┬®YogiGoddess of ┬®LDMMIA, ┬®LDMYoga.

ŌÖźTeacher Dept: (Rev Dr) Leslie Moore, ND Yoga (Aide/LPN Trained), Metaphysician,

Using Reiki Practitioner/Master Level Trained.

#yogigoddess @YogiGoddessVEVO

ŌÖźLDMMIA & Depts: are fusing the fan clubs so do welcome.

We are timeless and a safe haven / Cyber Space. ThatŌĆÖs the design of our Fan/Reader/Loyal Blog.ŌÖź

LDM HQ Est. in Ann Arbor, MI 2005.

- Moved to Detroit in 2006,

- Expanded online 2007-2024+

- Became a Beatz Studio in 2009 as Yogi Goddess. After our Apple Podcast

- Relocated to Mount Pleasant MI for College The Pandemic Ending.

- Endemic - Present; Moved back to assist Family in Metro Detroit.

Practitioner Student. Level/Session 2

* The Review & Topics:

* All virtual, adult, education students must be over 18 years to attend LDMMIA eClasses and vStudio Thx.

* Please refer to our Free Workshops anytime for review/notes.

*Tech: Products Sold Separately are for Uploading Size Reasons, THX.

MIA TECH: Videos under Copyright including our Music Video for Yogi Goddess, Can only be picked up vs shop downloaded. We are under vydia.com

Pickup will be our Youtube, for unlisted Playlist.

We do have another Vod for Session 2, Level 1.

After that we move on to Session 3.

Levels 1-3 should be done by August to Sept.

LDM Recording, Yogi Goddess Bio (ReverbNation)

Organization functions as a Studio 1st. We are a Media Co, Private Sector, and Global Listed.

Imagine we are 2 different studios. One for Yoga, the Other for Music Beatz. We are also Vevo TV for Smart TV and Youtube, 2 platforms. The audience differs.

Our Biz income are Media monetization within The Entertainment genre. This includes the category of Yoga, Reiki, ASMR, and Music Beatz. Any other tips, donations, B2C sales/Student Tuition are extra. The Biz gifts are appreciated. (We have been given a few $K for random emergencies.)

Paper 108 | ThoreauŌĆÖs Influence on Gandhi: The Evolution of Civil Disobedience

Paper 108 | ThoreauŌĆÖs Influence on Gandhi: The Evolution of Civil DisobedienceRajdeep Bavaliya

╠²

Dive into the powerful journey from ThoreauŌĆÖs 19thŌĆæcentury essay to GandhiŌĆÖs mass movement, and discover how one manŌĆÖs moral stand became the backbone of nonviolent resistance worldwide. Learn how conscience met strategy to spark revolutions, and why their legacy still inspires todayŌĆÖs social justice warriors. Uncover the evolution of civil disobedience. DonŌĆÖt forget to like, share, and follow for more deep dives into the ideas that changed the world.

M.A. Sem - 2 | Presentation

Presentation Season - 2

Paper - 108: The American Literature

Submitted Date: April 2, 2025

Paper Name: The American Literature

Topic: ThoreauŌĆÖs Influence on Gandhi: The Evolution of Civil Disobedience

[Please copy the link and paste it into any web browser to access the content.]

Video Link: https://youtu.be/HXeq6utg7iQ

For a more in-depth discussion of this presentation, please visit the full blog post at the following link: https://rajdeepbavaliya2.blogspot.com/2025/04/thoreau-s-influence-on-gandhi-the-evolution-of-civil-disobedience.html

Please visit this blog to explore additional presentations from this season:

Hashtags:

#CivilDisobedience #ThoreauToGandhi #NonviolentResistance #Satyagraha #Transcendentalism #SocialJustice #HistoryUncovered #GandhiLegacy #ThoreauInfluence #PeacefulProtest

Keyword Tags:

civil disobedience, Thoreau, Gandhi, Satyagraha, nonviolent protest, transcendentalism, moral resistance, Gandhi Thoreau connection, social change, political philosophySCHIZOPHRENIA OTHER PSYCHOTIC DISORDER LIKE Persistent delusion/Capgras syndr...

SCHIZOPHRENIA OTHER PSYCHOTIC DISORDER LIKE Persistent delusion/Capgras syndr...parmarjuli1412

╠²

SCHIZOPHRENIA INCLUDED TOPIC IS INTRODUCTION, DEFINITION OF GENERAL TERM IN PSYCHIATRIC, THEN DIFINITION OF SCHIZOPHRENIA, EPIDERMIOLOGY, ETIOLOGICAL FACTORS, CLINICAL FEATURE(SIGN AND SYMPTOMS OF SCHIZOPHRENIA), CLINICAL TYPES OF SCHIZOPHRENIA, DIAGNOSIS, INVESTIGATION, TREATMENT MODALITIES(PHARMACOLOGICAL MANAGEMENT, PSYCHOTHERAPY, ECT, PSYCHO-SOCIO-REHABILITATION), NURSING MANAGEMENT(ASSESSMENT,DIAGNOSIS,NURSING INTERVENTION,AND EVALUATION), OTHER PSYCHOTIC DISORDER LIKE Persistent delusion/Capgras syndrome(The Delusion of Doubles)/Acute and Transient Psychotic Disorders/Induced Delusional Disorders/Schizoaffective Disorder /CAPGRAS SYNDROME(DELUSION OF DOUBLE), GERIATRIC CONSIDERATION, FOLLOW UP, HOMECARE AND REHABILITATION OF THE PATIENT, Sustainable Innovation with Immersive Learning

Sustainable Innovation with Immersive LearningLeonel Morgado

╠²

Prof. Leonel and Prof. Dennis approached educational uses, practices, and strategies of using immersion as a lens to interpret, design, and planning educational activities in a sustainable way. Rather than one-off gimmicks, the intent is to enable instructors (and institutions) to be able to include them in their regular activities, including the ability to evaluate and redesign them.

Immersion as a phenomenon enables interpreting pedagogical activities in a learning-agnostic way: you take a stance on the learning theory to follow, and leverage immersion to envision and guide your practice.Tanja Vujicic - PISA for Schools contact Info

Tanja Vujicic - PISA for Schools contact InfoEduSkills OECD

╠²

Tanja Vujicic, Senior Analyst and PISA for SchoolŌĆÖs Project Manager at the OECD spoke at the OECD webinar 'Turning insights into impact: What do early case studies reveal about the power of PISA for Schools?' on 20 June 2025

PISA for Schools is an OECD assessment that evaluates 15-year-old performance on reading, mathematics, and science. It also gathers insights into studentsŌĆÖ learning environment, engagement and well-being, offering schools valuable data that help them benchmark performance internationally and improve education outcomes. A central ambition, and ongoing challenge, has been translating these insights into meaningful actions that drives lasting school improvement. Nutrition Assessment and Nutrition Education ŌĆō Unit 4 | B.Sc Nursing 5th Seme...

Nutrition Assessment and Nutrition Education ŌĆō Unit 4 | B.Sc Nursing 5th Seme...RAKESH SAJJAN

╠²

This PowerPoint presentation is based on Unit 4 ŌĆō Nutrition Assessment and Nutrition Education, a core topic in the 5th Semester of B.Sc Nursing under the subject Community Health Nursing ŌĆō I, as per the Indian Nursing Council (INC) guidelines.

The unit provides foundational knowledge of nutritional assessment techniques, importance of balanced diets, and health education strategies aimed at improving community nutrition. It empowers future nurses to play a key role in promoting nutrition, preventing malnutrition, and implementing dietary interventions at individual, family, and community levels.

Ō£ģ The PPT covers the following topics in detail:

Introduction to Nutrition and its role in health and disease prevention

Objectives of nutritional assessment in community settings

Types of nutritional assessment ŌĆō Anthropometric, Biochemical, Clinical, and Dietary (ABCD) methods

Tools and techniques used in each type of nutritional assessment

Interpreting growth charts, BMI, MUAC, and dietary recalls

Identification of malnutrition, both undernutrition and overnutrition

Common nutritional deficiencies ŌĆō protein-energy malnutrition, anemia, vitamin A deficiency, iodine deficiency

Principles of nutrition education and behavior change communication

Role of community health nurse in nutrition education during home visits, camps, and school health programs

Use of charts, posters, flashcards, and food models in health teaching

Culturally appropriate and locally available food suggestions

Strategies for promoting infant and young child feeding (IYCF)

National nutrition programs: POSHAN Abhiyaan, Mid-Day Meal Scheme, ICDS, and Anemia Mukt Bharat

Monitoring and evaluation of nutrition interventions

This PPT is perfect for:

B.Sc Nursing students preparing for unit tests or university exams

Nursing educators delivering community health lessons

Field work, community posting presentations, or group health teaching

Health educators and ASHA trainers working on community nutrition

All content is student-friendly, professionally formatted, and aligned with public health priorities and practical nursing roles.How to Manage Different Customer Addresses in Odoo 18 Accounting

How to Manage Different Customer Addresses in Odoo 18 AccountingCeline George

╠²

A business often have customers with multiple locations such as office, warehouse, home addresses and this feature allows us to associate with different addresses with each customer streamlining the process of creating sales order invoices and delivery orders.How to Customize Quotation Layouts in Odoo 18

How to Customize Quotation Layouts in Odoo 18Celine George

╠²

Customizing quotation layouts in Odoo 18 allows businesses to personalize their quotations to match branding or specific requirements. This can include adding logos, custom fields, or modifying headers and footers. Ad

Rootcellar design, Steve Belyea & Jim Merkel

- 1. Sustainability wonders: Bicycle Clothes line Condom Library Pad Thai Lady bugs Ceiling fan & The root cellar

- 2. Why are these Unity College students so serious? Solving a community problem Enrolled in the Environmental Citizen Service Learning Supplying a Community Need

- 3. My first root cellar -- under the cabin in British Columbia: Straw-bale and adobe Trap door in the kitchen Worked great but got moldy

- 4. My second root cellar experience: Under the Straw-Bale house Bucket system with ropes Compact Worked great, got moldy

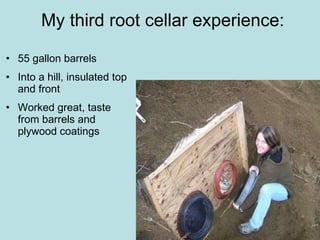

- 5. My third root cellar experience: 55 gallon barrels Into a hill, insulated top and front Worked great, taste from barrels and plywood coatings

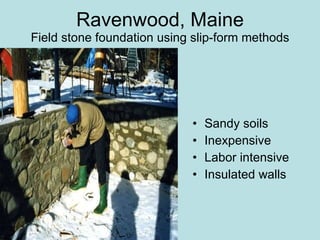

- 6. Ravenwood, Maine Field stone foundation using slip-form methods Sandy soils Inexpensive Labor intensive Insulated walls

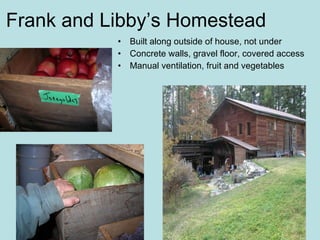

- 7. Frank and LibbyŌĆÖs Homestead Built along outside of house, not under Concrete walls, gravel floor, covered access Manual ventilation, fruit and vegetables

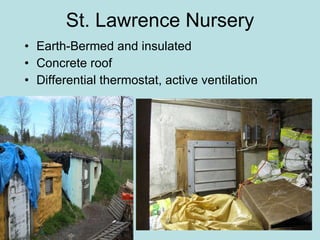

- 8. St. Lawrence Nursery Earth-Bermed and insulated Concrete roof Differential thermostat, active ventilation

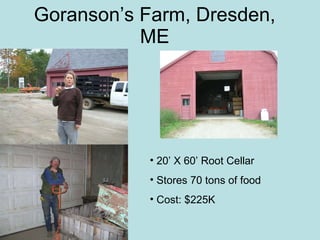

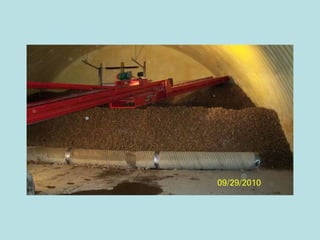

- 9. GoransonŌĆÖs Farm, Dresden, ME 20ŌĆÖ X 60ŌĆÖ Root Cellar Stores 70 tons of food Cost: $225K

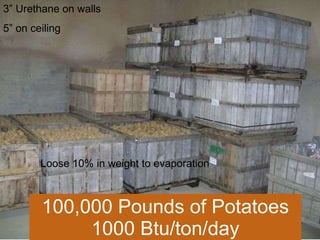

- 10. 100,000 Pounds of Potatoes 1000 Btu/ton/day Loose 10% in weight to evaporation 3ŌĆØ Urethane on walls 5ŌĆØ on ceiling

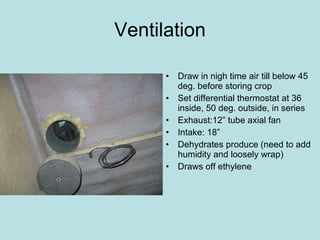

- 11. Ventilation Draw in nigh time air till below 45 deg. before storing crop Set differential thermostat at 36 inside, 50 deg. outside, in series Exhaust:12ŌĆØ tube axial fan Intake: 18ŌĆØ Dehydrates produce (need to add humidity and loosely wrap) Draws off ethylene

- 12. Dry Storage

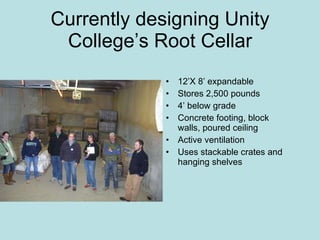

- 13. Currently designing Unity CollegeŌĆÖs Root Cellar 12ŌĆÖX 8ŌĆÖ expandable Stores 2,500 pounds 4ŌĆÖ below grade Concrete footing, block walls, poured ceiling Active ventilation Uses stackable crates and hanging shelves

- 14. Root Cellar Design Stephen Belyea Maine Department of Agriculture, Food, and Rural Resources

- 15. Storage is a period of rest : Not too warm, not too cool. Not too humid, not too dry. Just right!

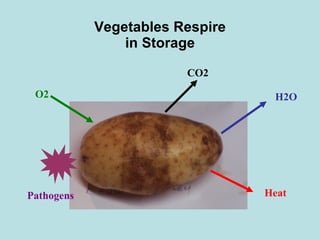

- 16. Vegetables Respire in Storage H2O CO2 O2 Heat Pathogens

- 17. Ideal Conditions Vary by Crop

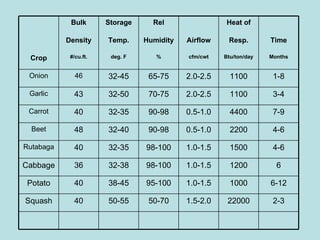

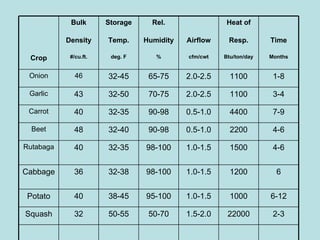

- 18. 2-3 22000 1.5-2.0 50-70 50-55 40 Squash 6-12 1000 1.0-1.5 95-100 38-45 40 Potato 6 1200 1.0-1.5 98-100 32-38 36 Cabbage 4-6 1500 1.0-1.5 98-100 32-35 40 Rutabaga 4-6 2200 0.5-1.0 90-98 32-40 48 Beet 7-9 4400 0.5-1.0 90-98 32-35 40 Carrot 3-4 1100 2.0-2.5 70-75 32-50 43 Garlic 1-8 1100 2.0-2.5 65-75 32-45 46 Onion Months Btu/ton/day cfm/cwt % deg. F #/cu.ft. Crop Time Resp. Airflow Humidity Temp. Density Heat of Rel Storage Bulk

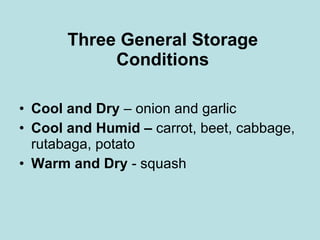

- 19. Three General Storage Conditions Cool and Dry ŌĆō onion and garlic Cool and Humid ŌĆō carrot, beet, cabbage, rutabaga, potato Warm and Dry - squash

- 20. Do these conditions occur naturally on a consistent basis? Certainly Not! How can we provide the storage conditions our stored crops need? We need to be able to control the environment in our storages.

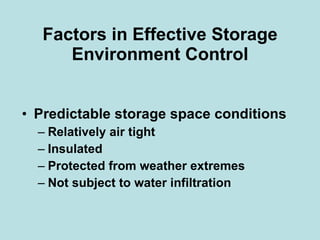

- 21. Factors in Effective Storage Environment Control Predictable storage space conditions Relatively air tight Insulated Protected from weather extremes Not subject to water infiltration

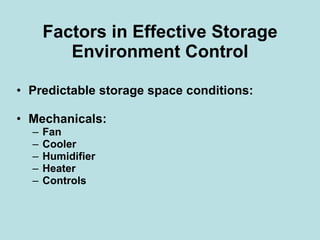

- 22. Factors in Effective Storage Environment Control Predictable storage space conditions: Mechanicals: Fan Cooler Humidifier Heater Controls

- 23. 2-3 22000 1.5-2.0 50-70 50-55 32 Squash 6-12 1000 1.0-1.5 95-100 38-45 40 Potato 6 1200 1.0-1.5 98-100 32-38 36 Cabbage 4-6 1500 1.0-1.5 98-100 32-35 40 Rutabaga 4-6 2200 0.5-1.0 90-98 32-40 48 Beet 7-9 4400 0.5-1.0 90-98 32-35 40 Carrot 3-4 1100 2.0-2.5 70-75 32-50 43 Garlic 1-8 1100 2.0-2.5 65-75 32-45 46 Onion Months Btu/ton/day cfm/cwt % deg. F #/cu.ft. Crop Time Resp. Airflow Humidity Temp. Density Heat of Rel. Storage Bulk

- 24. Sizing a Storage Unit Assume that the bulk density is approximately 40 lbs. / cu.ft. Only 75% of floor space is usable. Good air circulation. Leave space for easy access to different products. Shelves or pallets increase the total capacity by more efficient space utilization.

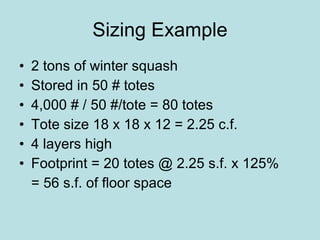

- 25. Sizing Example 2 tons of winter squash Stored in 50 # totes 4,000 # / 50 #/tote = 80 totes Tote size 18 x 18 x 12 = 2.25 c.f. 4 layers high Footprint = 20 totes @ 2.25 s.f. x 125% = 56 s.f. of floor space

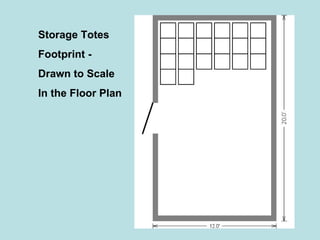

- 26. Storage Totes Footprint - Drawn to Scale In the Floor Plan

- 27. Ventilation Summer and early Fall ŌĆō remove Field Heat and Heat of Respiration Usually requires refrigeration Usually short term storage Late Fall and Winter ŌĆō remove heat of respiration Also have to consider heat gain through structure

- 28. Cooling with Outside Air Most economical cooling method Amount of cooling air required will vary significantly from day to day and week to week as outside air temperatures vary and as cooling load in the storage locker changes. Requires at least minimal controls

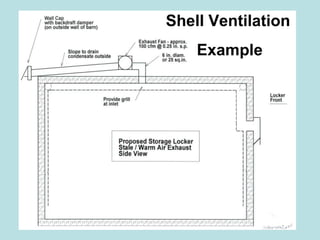

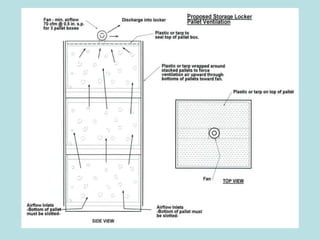

- 29. Shell Ventilation Cools inside of locker or storage room. Produce relies on air circulation through room and around bins / bags. Generally need 0.25 ŌĆō 0.50 cfm / cwt of stored product. Multiple fans or variable speed fans are most effective for varying conditions.

- 31. ╠²

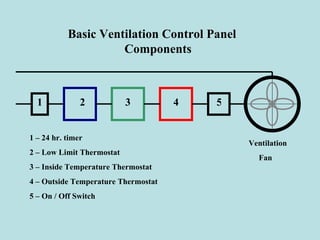

- 32. 2 3 4 5 1 1 ŌĆō 24 hr. timer 2 ŌĆō Low Limit Thermostat 3 ŌĆō Inside Temperature Thermostat 4 ŌĆō Outside Temperature Thermostat 5 ŌĆō On / Off Switch Ventilation Fan Basic Ventilation Control Panel Components

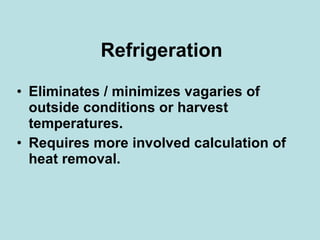

- 34. Refrigeration Eliminates / minimizes vagaries of outside conditions or harvest temperatures. Requires more involved calculation of heat removal.

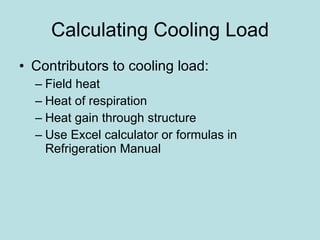

- 35. Calculating Cooling Load Contributors to cooling load: Field heat Heat of respiration Heat gain through structure Use Excel calculator or formulas in Refrigeration Manual

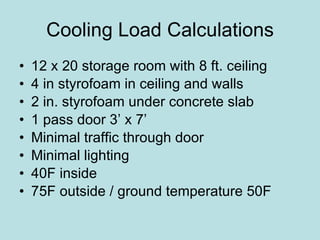

- 36. Cooling Load Calculations 12 x 20 storage room with 8 ft. ceiling 4 in styrofoam in ceiling and walls 2 in. styrofoam under concrete slab 1 pass door 3ŌĆÖ x 7ŌĆÖ Minimal traffic through door Minimal lighting 40F inside 75F outside / ground temperature 50F

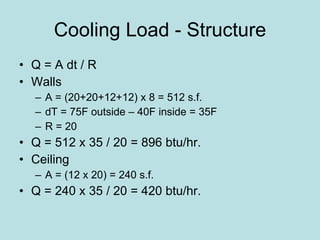

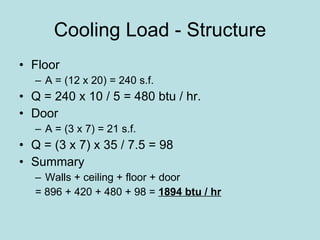

- 37. Cooling Load - Structure Q = A dt / R Walls A = (20+20+12+12) x 8 = 512 s.f. dT = 75F outside ŌĆō 40F inside = 35F R = 20 Q = 512 x 35 / 20 = 896 btu/hr. Ceiling A = (12 x 20) = 240 s.f. Q = 240 x 35 / 20 = 420 btu/hr.

- 38. Cooling Load - Structure Floor A = (12 x 20) = 240 s.f. Q = 240 x 10 / 5 = 480 btu / hr. Door A = (3 x 7) = 21 s.f. Q = (3 x 7) x 35 / 7.5 = 98 Summary Walls + ceiling + floor + door = 896 + 420 + 480 + 98 = 1894 btu / hr

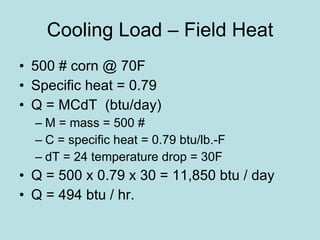

- 39. Cooling Load ŌĆō Field Heat 500 # corn @ 70F Specific heat = 0.79 Q = MCdT (btu/day) M = mass = 500 # C = specific heat = 0.79 btu/lb.-F dT = 24 temperature drop = 30F Q = 500 x 0.79 x 30 = 11,850 btu / day Q = 494 btu / hr.

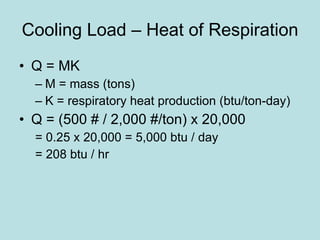

- 40. Cooling Load ŌĆō Heat of Respiration Q = MK M = mass (tons) K = respiratory heat production (btu/ton-day) Q = (500 # / 2,000 #/ton) x 20,000 = 0.25 x 20,000 = 5,000 btu / day = 208 btu / hr

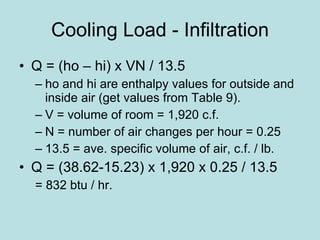

- 41. Cooling Load - Infiltration Q = (ho ŌĆō hi) x VN / 13.5 ho and hi are enthalpy values for outside and inside air (get values from Table 9). V = volume of room = 1,920 c.f. N = number of air changes per hour = 0.25 13.5 = ave. specific volume of air, c.f. / lb. Q = (38.62-15.23) x 1,920 x 0.25 / 13.5 = 832 btu / hr.

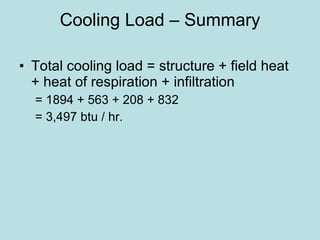

- 42. Cooling Load ŌĆō Summary Total cooling load = structure + field heat + heat of respiration + infiltration = 1894 + 563 + 208 + 832 = 3,497 btu / hr.

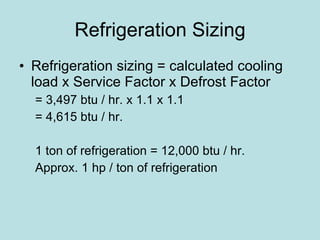

- 43. Refrigeration Sizing Refrigeration sizing = calculated cooling load x Service Factor x Defrost Factor = 3,497 btu / hr. x 1.1 x 1.1 = 4,615 btu / hr. 1 ton of refrigeration = 12,000 btu / hr. Approx. 1 hp / ton of refrigeration

- 44. ╠²

- 46. Air Conditioner Cool Bot Application?

- 47. Humidification

- 50. ╠²

- 52. ╠²

- 53. ╠²

- 54. Hygrometer

- 61. Easy Access

- 62. Easy Access / Easy Clean Up Well Lighted

- 63. Questions ŌĆ” and maybe Answers

- 64. Small Electric Space Heater

- 65. ╠²

- 66. ╠²