Rotor spinning a basic, process of spinning

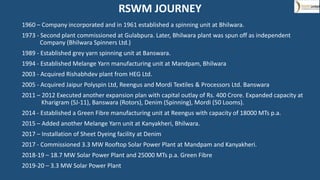

- 1. RSWM JOURNEY 1960 – Company incorporated and in 1961 established a spinning unit at Bhilwara. 1973 - Second plant commissioned at Gulabpura. Later, Bhilwara plant was spun off as independent Company (Bhilwara Spinners Ltd.) 1989 - Established grey yarn spinning unit at Banswara. 1994 - Established Melange Yarn manufacturing unit at Mandpam, Bhilwara 2003 - Acquired Rishabhdev plant from HEG Ltd. 2005 - Acquired Jaipur Polyspin Ltd, Reengus and Mordi Textiles & Processors Ltd. Banswara 2011 – 2012 Executed another expansion plan with capital outlay of Rs. 400 Crore. Expanded capacity at Kharigram (SJ-11), Banswara (Rotors), Denim (Spinning), Mordi (50 Looms). 2014 - Established a Green Fibre manufacturing unit at Reengus with capacity of 18000 MTs p.a. 2015 – Added another Melange Yarn unit at Kanyakheri, Bhilwara. 2017 – Installation of Sheet Dyeing facility at Denim 2017 - Commissioned 3.3 MW Rooftop Solar Power Plant at Mandpam and Kanyakheri. 2018-19 – 18.7 MW Solar Power Plant and 25000 MTs p.a. Green Fibre 2019-20 – 3.3 MW Solar Power Plant

- 2. RSWM REENGUS Synthetic yarn Effect yarn Polyester Viscose Blended Slub Effect Viscose 100% Injection Slub Polyester 100% Roving Grindle Polyester Acrylic Blended Melange Polyester Cotton Blended Spindles : Synthetic 32736 Production Capacity 33 MT/Day Count range 8s to 40s

- 3. RSWM RISHABDEV Spindles Production Capacity 50.7 MT/Day 52704 Count range 8s to 40s Synthetic yarn Viscose yarn Special fibre Effect yarn Viscose 100% Viscose Blended Viscose with Modal, Tencel, Bamboo, Excel Viscose Linen Slub Polyester 100% Polyester Blended Cationic Injection Slub Neppy Slub Lycra

- 4. RSWM KHARIGRAM Spindles : Synthetic Production Capacity 136 MT/Day 167136 Count range 6s to 60s Synthetic yarn Dyed yarn Effect yarn Acrylic 100% Acrylic blended Poly Viscose Slub Viscose 100% Viscose Blended Poly Cotton Core spun Polyester 100% Polyester Blended 100% Polyester Neppy yarn 100% Acrylic Roving Grindle D/F Grindle

- 5. RSWM BANSWARA Spindles : Synthetic Cotton Production Capacity 99 MT/Day 63600 31104 Count range 6s to 60s Synthetic yarn Cotton yarn Special fibre Effect yarn Acrylic 100% Acrylic blended Cotton 100% Coolmax Slub Viscose 100% Viscose Blended Cotton with Modal, Tencel, Bamboo Thermolite Injection Slub Polyester 100% Polyester Blended Siro Lycra Rotors 3140

- 6. 6 Spinning mills and Capacity - State wise Central India No. of Mills Spindles (Mio) Rotors('000) Maharashtra 110 3.49 25.64 Gujarat 163 3.81 48.94 W. Bengal + Orissa 15 0.44 2.13 Total 288 7.74 76.71 North India - I No. of Mills Spindles (Mio) Rotors('000) Punjab & Kashmir 157 4.51 102.21 Himachal Pradesh 21 0.8 10.84 Haryana 80 0.31 97.08 Madhya Pradesh - I 7 1.45 12.96 Total 265 7.07 223.09 North India - II No. of Mills Spindles (Mio) Rotors('000) Madhya Pradesh - II 37 0.96 13.68 UP + Uttaranchal 28 0.57 8.35 Rajasthan 36 1.9 28.86 Total 101 3.43 50.89 WB Punjab Rajasthan Madyah Pradesh Uttar Pradesh Bihar Gujarat Orissa Andhra Pradesh Maharashtra Karnataka Tamil Nadu Kerala Bhutan Bangladesh Jammu and Kashmir Himachal Pradesh Haryana Uttrakhand India No. of Mills Spindles (Mio) Rotors('000) North India - I 265 7.07 223.09 North India - II 101 3.43 50.89 Central India 288 7.74 76.71 South India 1152 22.96 369.32 Total 1806 41.2 720.01 Installed spindles and customer coverage South India No. of Mills Spindles (Mio) Rotors('000) Tamilnadu 979 17.86 326.46 Andhra Pradesh 138 3.98 37.56 Kerela 18 0.44 1.7 Karnataka 17 0.68 3.6 Total 1152 22.96 369.32 Now currently India harbours 50+ millions spindles across states and approx. 36% rise in rotors till 2022. 2019

- 7. RING SPINNING YARN PROCESS FLOW DRAWING (Homogenising fibre) LAP FORMER COMBER RING FRAME (Yarn creation) ROVING FRAME DRAWING (II Passage) AUTOCONER (Final Package)

- 8. ROTOR and NON CONVENTIONAL SPINNING YARN PROCESS FLOW ROTOR MACHINE (Final package) DRAWING (Homogenising fibre)

- 10. Rotor-spun compound yarns have such advantages as consistent strength, good evenness, structural stability and less hairiness. The process flow of rotor-spun compound yarns is shorter than that of ring- spun–compound yarns, and the productivity is higher. Why Rotor spun yarns

- 16. 23 26

- 29. point insert 1 turn twist

- 54. Something Hatke

- 55. Lycra spinning on Rotor

- 56. Thank you.