Run charts

- 1. Run Charts Adding the element of time will help clarify your understanding of the causes of variation in your processes. A run chart is a line graph of data points organized in time sequence and centered on the median data value. The patterns in the run chart can help you find where to look for assignable causes of variation. What can it do for you? Histograms or frequency plots can show you the general distribution or variation among a collection of data points representing a process, but one histogram or one frequency plot can not show you trends or help pinpoint unusual events. Sometimes, a normal-looking distribution will hide trends or other unusual data. To spot those trends, the data must be considered in time order. Plotting data on a run chart can help you identify trends and relate them to the time they occurred. This will help you in your search for the special causes that may be adding variation Unusual variation can hide in a frequency plot to your process. Run charts are especially valuable in the measure and analyze phases of Lean Six Sigma methodology.

- 2. How do you do it? 1. Select a characteristic from one of your processes. This characteristic could be presenting a problem because excessive variation often drives it outside of specification limits, or it could be a cause of customer complaints. 2. Measure the characteristic over time intervals and record the data. Note the time or the time period that is associated with each data point. 3. Find the median data value. To do this, list the data values in numeric order. Include each data point, even if it is a repeat value. If the number of data points is odd, the median is the middle value. If the number of data points is even, the median is halfway between the two values nearest the middle. For example, if the collected data points were: 5, 1, 18, 8, 12, 9, the ordered values would be: 1, 5, 8, 9, 12, and 18. The middlemost values are 8 and 9. The median is the average of those values, or 8.5. (Remember, the numerically-ordered data is only for determining the median. The data must be plotted in time order on the run chart to be of any value.) 4. Set up the scales for your run chart. The vertical scale will be the data values, and the horizontal scale will be the time. Make the horizontal scale about two to three times the distance of the vertical scale. 5. Label the vertical scale so that the values will be centered approximately on the median and so the scale is about 1 ½ to 2 times the range of the collected data. 6. Draw a horizontal line representing the median value. 7. Plot the data points in sequence. Connect each point to the next point in the sequence with a line. int ta ns ns int ta ns ns of r of r of r of r er t fo er t fo er t fo er t fo po f da po f da ru ru ru ru Some special cause variation reveals s s mb mi mb mi mb mi mb mi o o itself in unusual run-chart patterns. nu r li r li nu r li nu r li er er These clues can direct you in your mb mb we we pe pe Up Up search for causes. Count the number Lo Lo Nu Nu nu of runs. Runs are sequences of points 10 3 8 35 13 23 11 3 9 36 13 24 that stay on one side of, either above 12 3 10 37 13 25 or below, the median line. One way 13 4 10 38 14 25 14 4 11 39 14 26 of counting the runs is to circle these 15 4 12 40 15 26 sequences and tally them. Another 16 5 12 41 16 26 17 5 13 42 16 27 way of doing this is to count the 18 6 13 43 17 27 number of times the run-line crosses 19 6 14 44 17 28 20 6 15 45 17 29 the median, and then add one. 21 7 15 46 17 30 22 7 16 47 18 30 23 8 16 48 18 31 Compare the number of runs you 24 8 17 49 19 31 count to the accompanying chart. 25 9 17 50 19 32 26 9 18 60 24 37 27 9 19 70 28 43 Numbers of runs outside the range 28 10 19 80 33 48 shown for the number of data points 29 10 20 90 37 54 30 11 20 100 42 59 are statistically unusual. 31 11 21 110 46 65 32 11 22 120 51 70 33 11 22 34 12 23

- 3. Too few runs (below the lower limit) generally indicate that something cyclic is systematically shifting the process average. Example of too few runs Too many runs could point to a problem of consecutive, over-compensating process adjustments or indicate that the data points actually came from two sources with different process averages. Example of too many runs

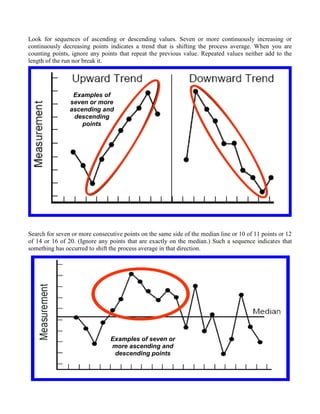

- 4. Look for sequences of ascending or descending values. Seven or more continuously increasing or continuously decreasing points indicates a trend that is shifting the process average. When you are counting points, ignore any points that repeat the previous value. Repeated values neither add to the length of the run nor break it. Examples of seven or more ascending and descending points Search for seven or more consecutive points on the same side of the median line or 10 of 11 points or 12 of 14 or 16 of 20. (Ignore any points that are exactly on the median.) Such a sequence indicates that something has occurred to shift the process average in that direction. Examples of seven or more ascending and descending points

- 5. A sequence of 14 or more data points alternating up and down suggests a variation related to sampling (such as one reading early in the day and one reading toward the end) or that the data is coming from two sources with different process averages (such as from two machines making the same part.) In looking for up-and-down alternation, ignore any points that are exactly the same as the preceding point. Example of 14 or more alternating points A sequence of seven or more points with exactly the same value usually should signal you to look for a special cause. While it is possible that your process has improved to the extent that the existing measurement technique is no longer sensitive enough to measure variation, it is usually more probable that a gauge is stuck or broken or that someone is making up the data. Example of seven points in a row with the same value

- 6. Now what? Run charts can be very valuable in helping your search for sources of variation. They are easy to plot and easy to interpret. The sampling is uncomplicated, and there are no statistical computations to make. They can also be applied to almost any process or any data. On the other hand, they are not an instant indicator. They are best used for spotting trends; short shifts in the process cannot always be detected with run charts. In addition, special causes that produce general piece-to-piece variation will not be readily detected on run charts. Finally, a simple run chart cannot establish the natural capabilities of a process, so it isn’t possible to use one to predict what specifications a process can actually meet. To do that, you need to create a control chart, a run chart with statistical control limits. Steven Bonacorsi is the President of the International Standard for Lean Six Sigma (ISLSS) and Certified Lean Six Sigma Master Black Belt instructor and coach. Steven Bonacorsi has trained hundreds of Master Black Belts, Black Belts, Green Belts, and Project Sponsors and Executive Leaders in Lean Six Sigma DMAIC and Design for Lean Six Sigma process improvement methodologies. Author for the Process Excellence Network (PEX Network / IQPC). FREE Lean Six Sigma and BPM content International Standard for Lean Six Sigma Steven Bonacorsi, President and Lean Six Sigma Master Black Belt 47 Seasons Lane, Londonderry, NH 03053, USA Phone: + (1) 603-401-7047 Steven Bonacorsi e-mail Steven Bonacorsi LinkedIn Steven Bonacorsi Twitter Lean Six Sigma Group