Safety presentation isolation and tagging

- 1. SAFETY PRESENTATION ISOLATION AND TAGGING

- 2. ISOLATION AND TAGGING You isolate to stop : • A motor from switching on (or off) • A substance such as liquid, gas or powder getting in or out • Two hazardous substances mixing 2

- 3. ISOLATION AND TAGGING You isolate to : • Allow maintenance or inspection • Take a piece of plant out of service for a certain time • Change a process • Make sure that even isolated plant cannot be started by mistake somewhere else • Stop the chance of human error or mechanical failure 3

- 4. ISOLATION AND TAGGING Isolation of equipment will make sure: • That it will not start while you are working on it • All persons working on the machine are protected • Damage to the equipment is prevented. 4

- 5. ISOLATION AND TAGGING Isolation points can be : • battery isolator switches • air or water system gate/shut off valves • electrical switches or any other physical means of ensuring personnel can not turn on the energy source. 5

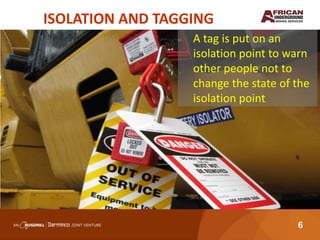

- 6. ISOLATION AND TAGGING A tag is put on an isolation point to warn other people not to change the state of the isolation point 6

- 7. ISOLATION AND TAGGING AUMS uses four basic types of tags • Out of Service • Personal Danger • Commissioning and Testing • Information 7

- 8. ISOLATION AND TAGGING ISOLATION AND TAGGING OUT OF SERVICE These tags are used to prevent defective equipment being started, operated or used which may result in injury to personnel or further equipment damage. 8

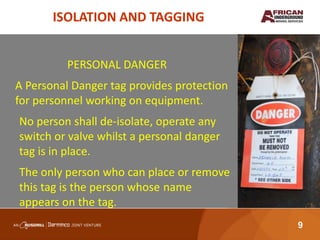

- 9. ISOLATION AND TAGGING PERSONAL DANGER A Personal Danger tag provides protection for personnel working on equipment. No person shall de-isolate, operate any switch or valve whilst a personal danger tag is in place. The only person who can place or remove this tag is the person whose name appears on the tag. 9

- 10. ISOLATION AND TAGGING COMMISSIONING AND TESTING This tag gives an employee exclusive control over the plant operation. It is used during commissioning, calibration, testing, inspection and maintenance when equipment is required to be in operating mode. 10

- 11. ISOLATION AND TAGGING ISOLATION AND TAGGING INFORMATION TAGS These tags are used to pass on information which may reduce inefficiencies, doubling up or constant reporting. 11

- 12. ISOLATION AND TAGGING Equipment must be isolated and tagged with an OUT OF SERVICE tag at each isolation point 12

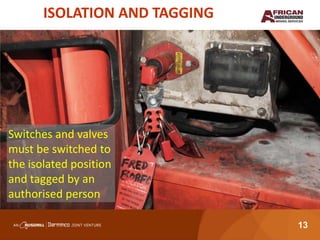

- 13. ISOLATION AND TAGGING Switches and valves must be switched to the isolated position and tagged by an authorised person 13

- 14. ISOLATION AND TAGGING Each person working on the equipment must have a PERSONAL DANGER tag at each isolation point 14

- 15. ISOLATION AND TAGGING ISOLATION AND TAGGING Before starting work, test the isolation. Discharge any energy that MIGHT be stored in the system. Each person must remove his or her own Personal Danger Tag at the completion of the job or prior to leaving the work site. If the task is incomplete, the Out of Service tag remains on the isolation point. Always communicate isolation conditions with your supervisor and the supervisor of the next crew coming on shift. 15

- 16. SAFETY PRESENTATION THANK YOU