Screw metrology

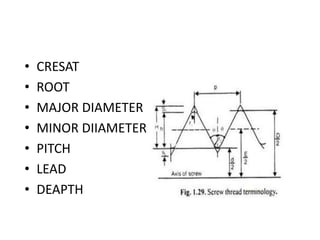

- 3. âĒ CRESAT âĒ ROOT âĒ MAJOR DIAMETER âĒ MINOR DIIAMETER âĒ PITCH âĒ LEAD âĒ DEAPTH

- 6. measurements (i) Major diameter, (ii) Minor diameter, (iii) Pitch diameter, (iv) Pitch, (v) Included angle, (vi) Thread form, (vii) Thread flank angle, etc.

- 7. Errors in Major and Minor Diameters This error is due to improper machine setting. Errors on major and minor diameter will cause. (a) Interference between mating threads, preventing engagement between mating bolt and nut. (b) Reduction in flank contact, if the error is in the other direction. It may lead to and excessive weakening of the threads and too much slackness between the mating parts

- 8. Errors in Pitch (a)Progressive Error (b)Periodic Error (c) Erratic Error

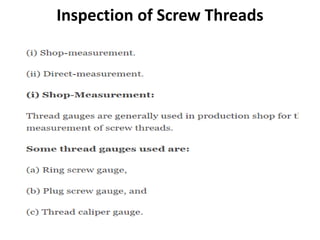

- 10. Inspection of Screw Threads

- 11. Ring Screw Gauge The Ring screw gauge has similar principle to a plain ring gauge, except that screw threads are cut on the inner surface of the ring screw gauge. Ring screw gauge in used to check screw threads on outside of cylindrical objects like bolts and shafts. They may be âGoâ and âNot-Goâ types.

- 12. Plug Screw Gauge

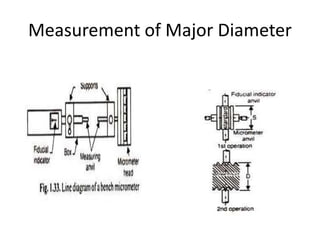

- 14. Measurement of Major Diameter

- 16. Measurement of Minor Diameter

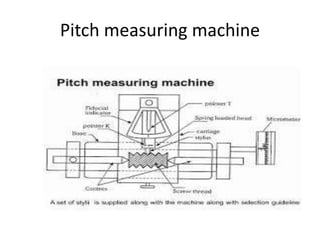

- 17. Pitch measurement âĒ Pitch measuring machine âĒ Tmm âĒ Screw pitch gauge

- 18. Screw pitch gauge pic working