Self-Compacting Concrete: Composition, Properties, and Applications in Modern Construction

- 1. PRESENTED BY : GYANESHWAR VAYAS Department of civil engineering [M.Tech] (2421309) Presentation on Self Compacting Concrete Under the Guidance Of Dr.Bijan Kumar Roy

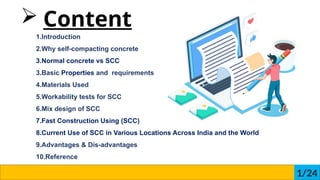

- 2. ? Content 1.Introduction 2.Why self-compacting concrete 3.Normal concrete vs SCC 3.Basic Properties and requirements 4.Materials Used 5.Workability tests for SCC 6.Mix design of SCC 7.Fast Construction Using (SCC) 8.Current Use of SCC in Various Locations Across India and the World 9.Advantages & Dis-advantages 10.Reference 1/24

- 3. 1. Development of SCC INTRODUCTION Figure 1: Reinforcement Details of a Complex Source: www.denverwater.org ?The concept of Self-Compacting Concrete (SCC) was first proposed in 1986. ?2.Professor H. Okamura introduced this concept. ?He was from Kochi University of Technology, Japan. 2/24

- 4. 1.Flexible Design ©C Can be used for any shape. 2.Better Reinforcement ©C Fills gaps around steel bars easily. 3.High Quality ©C Dense and uniform concrete. 4.Smooth Finish ©C Looks visually appealing. 5.Durable ©C Resists chemicals and gains strength early. ? Why self-compacting concrete..? Figure 2: Flowability of Self-Compacting Concrete (GIF) Source: www.youtube.com/@concrete-steel-timber3/24

- 5. ContinueĪŁĪŁ 6.Easy Casting ©C Faster and simpler pouring. 7.Efficient ©C Requires less labor. 8.Safer Work ©C Better working conditions. 9.Eco-friendly ©C Reduces noise and pollution. 10.Cost-Effective ©C Saves on formwork and lasts longer. Figure 3: Easy Casting ©C Faster and Simpler Pouring (GIF) Source: www.youtube.com/@concrete-steel-timber 4/24

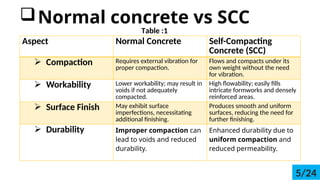

- 6. ?Normal concrete vs SCC Aspect Normal Concrete Self-Compacting Concrete (SCC) ? Compaction Requires external vibration for proper compaction. Flows and compacts under its own weight without the need for vibration. ? Workability Lower workability; may result in voids if not adequately compacted. High flowability; easily fills intricate formworks and densely reinforced areas. ? Surface Finish May exhibit surface imperfections, necessitating additional finishing. Produces smooth and uniform surfaces, reducing the need for further finishing. ? Durability Improper compaction can lead to voids and reduced durability. Enhanced durability due to uniform compaction and reduced permeability. Table :1 5/24

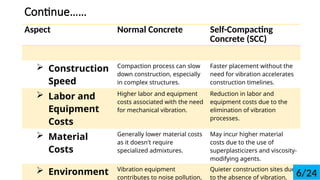

- 7. ContinueĪŁĪŁ Aspect Normal Concrete Self-Compacting Concrete (SCC) ? Construction Speed Compaction process can slow down construction, especially in complex structures. Faster placement without the need for vibration accelerates construction timelines. ? Labor and Equipment Costs Higher labor and equipment costs associated with the need for mechanical vibration. Reduction in labor and equipment costs due to the elimination of vibration processes. ? Material Costs Generally lower material costs as it doesn't require specialized admixtures. May incur higher material costs due to the use of superplasticizers and viscosity- modifying agents. ? Environment Vibration equipment contributes to noise pollution, Quieter construction sites due to the absence of vibration, 6/24

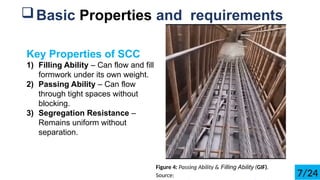

- 8. ?Basic Properties and requirements Key Properties of SCC 1) Filling Ability ©C Can flow and fill formwork under its own weight. 2) Passing Ability ©C Can flow through tight spaces without blocking. 3) Segregation Resistance ©C Remains uniform without separation. Figure 4: Passing Ability & Filling Ability (GIF). Source: 7/24

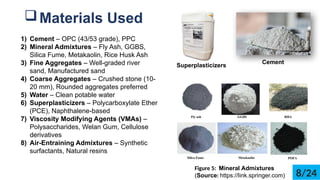

- 9. ?Materials Used 1) Cement ©C OPC (43/53 grade), PPC 2) Mineral Admixtures ©C Fly Ash, GGBS, Silica Fume, Metakaolin, Rice Husk Ash 3) Fine Aggregates ©C Well-graded river sand, Manufactured sand 4) Coarse Aggregates ©C Crushed stone (10- 20 mm), Rounded aggregates preferred 5) Water ©C Clean potable water 6) Superplasticizers ©C Polycarboxylate Ether (PCE), Naphthalene-based 7) Viscosity Modifying Agents (VMAs) ©C Polysaccharides, Welan Gum, Cellulose derivatives 8) Air-Entraining Admixtures ©C Synthetic surfactants, Natural resins Cement Figure 5: Mineral Admixtures (Source: https://link.springer.com) Superplasticizers 8/24

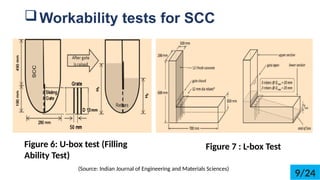

- 10. ?Workability tests for SCC Figure 7 : L-box Test Figure 6: U-box test (Filling Ability Test) (Source: Indian Journal of Engineering and Materials Sciences) 9/24

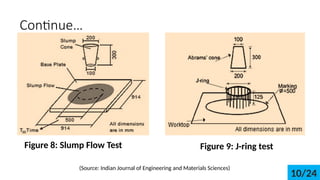

- 11. ContinueĪŁ Figure 8: Slump Flow Test Figure 9: J-ring test (Source: Indian Journal of Engineering and Materials Sciences) 10/24

- 12. ? Key Points for M80 SCC Mix Design: 1.Low Water-Powder Ratio (w/p) ©C Typically 0.25 to 0.30 for high strength. 2.Use of Superplasticizer ©C To enhance workability and self-compactability. 3.Addition of Silica Fume or Fly Ash ©C Improves durability, reduces permeability. 4.Aggregate Size Limited to 12 mm ©C Ensures better flow and avoids blocking in reinforcement. 5.Use of VMA (if needed) ©C Prevents segregation and enhances mix stability M80 Figure 10 : Concrete Cube 11/24

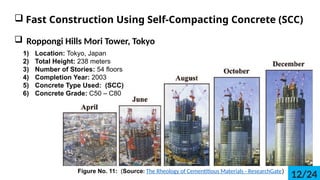

- 13. ? Fast Construction Using Self-Compacting Concrete (SCC) 1) Location: Tokyo, Japan 2) Total Height: 238 meters 3) Number of Stories: 54 floors 4) Completion Year: 2003 5) Concrete Type Used: (SCC) 6) Concrete Grade: C50 ©C C80 ? Roppongi Hills Mori Tower, Tokyo Figure No. 11: (Source: The Rheology of Cementitious Materials - ResearchGate) 12/24

- 14. ? Current Use of SCC in Various Locations Across India and the World ?Figure 12 : Palais Royale, Mumbai: 1) Location: Mumbai, India 2) Total Height: 320 meters 3) Number of Stories: 88 floors 4) Completion Year: Ongoing (Construction started in 2008) 5) Concrete Grade Used: M50 6) Type of Concrete: Self-Compacting Concrete (SCC) 7) Placement Method: Pumped for high- rise construction Figure : 12 (Source: Channeliam.com ) 13/24

- 15. ? Kesar Solitaire, 1) Location: Navi Mumbai, India 2) Total Height: Approx. 100 meters 3) Number of Stories: 26 floors 4) Completion Year: N/A 5) Concrete Grade Used: M40 6) Type of Concrete: Self-Compacting Concrete (SCC) 7) Placement Method: Pumped for high-rise construction 8) Reason for Using SCC: Enhanced strength, ease of placement in dense reinforcement, reduced labor, and improved surface finish. Figure : 13 (Source: in.pinterest.com) 14/24

- 16. ? Figure 14 : Delhi Metro Rail Corporatio n (DMRC) Projects (M40 to M60) (Source:www.nd tv.com) 15/24

- 17. ? 16/24

- 18. Figure : 16 (Source: Pixabay.com) ?Bandra-Worli Sea Link, Mumbai 1) Location: Mumbai, India 2) Total Length: 5.6 km 3) Height of Towers: 128 m 4) Number of Lanes: 8 lanes 5) Completion Year: 2009 6) Concrete Grade Used: M50 ©C M60 7) Type of Concrete: Self- Compacting Concrete (SCC) & High- Performance Concrete (HPC) 17/24

- 19. ?Purvanchal Expressway (UP) ©C SCC used in pier caps & deck slabs. 1. Location: Uttar Pradesh, India 2. Current Lanes: 6 lanes (3 lanes each direction) 3. Expandable to: 8 lanes (future-ready) 4. Concrete Grade Used: M50-M60 5. Concrete Type: Self- Compacting Concrete (SCC) & High- Performance Concrete (HPC) Figure 17 : (Source: www.jagranjosh.com) Purvanchal Expressway 18/24

- 20. ? Arlanda Airport Control Tower, Stockholm, Sweden ©C 1) Height: 83m, Stories: 20, Completed: 2001, 2) Purpose: Air traffic control, Concrete Type: Self-Compacting Concrete (SCC), 3) Grade: C50/60, Placement: Pumped without vibration ? C50/60 concrete means 50 MPa cylindrical strength and 60 MPa cube strength C50/60 is a high-strength concrete grade based on European standard EN 206 Figure 18 : (Source: Recent Advances in Self-Compacting Concrete - NBMC W 19/24

- 21. ? Trump Tower, New York City 1) Location: New York City, USA 2) Total Height: 202 meters (664 ft) 3) Number of Stories: 58 floors 4) Completion Year: 1983 5) Concrete Grade Used: High- Strength Concrete (Up to 85 MPa) 6) Type of Concrete: Self- Compacting Concrete (SCC) & High-Performance Concrete (HPC) 7) Placement Method: Pumped into high-rise formwork Figure 19: (Source: Recent Advances in Self-Compacting Concrete - NBMCW) 20/24

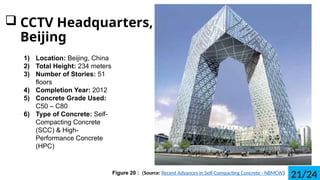

- 22. ? CCTV Headquarters, Beijing 1) Location: Beijing, China 2) Total Height: 234 meters 3) Number of Stories: 51 floors 4) Completion Year: 2012 5) Concrete Grade Used: C50 ©C C80 6) Type of Concrete: Self- Compacting Concrete (SCC) & High- Performance Concrete (HPC) Figure 20 : (Source: Recent Advances in Self-Compacting Concrete - NBMCW) 21/24

- 23. Advantages & Dis-advantages No. Advantages Disadvantages 1. Better Flowability ©C Easily fills complex formwork. Higher Material Cost ©C Requires more cement and additives. 2. Reduced Labor Costs ©C No need for vibration. Sensitive Mix Design ©C Small changes affect performance. 3. Improved Surface Finish ©C Smooth and defect-free. Specialized Testing Needed ©C Workability tests required. 4. Higher Durability ©C Dense concrete with low permeability. Higher Shrinkage Risk ©C More prone to plastic shrinkage. 5. Faster Construction ©C Speeds up the casting process. Limited Field Experience ©C Less common than conventional concrete. 22/24 Table : 2

- 24. ?References 1.Laskar, A. I. (2015). Concrete Technology Practices. Narosa Publishing House (Professor, NIT Silchar). 2.Government of Maharashtra WRD Handbook (n.d.). Chapter 3: Self-Compacting Concrete. WRD Maharashtra. 3.Rich, D., et al. (2012). UK ContractorsĪ» Views on Self-Compacting Concrete in Construction. Proc. ICE - Construction Materials. 4.Flatt, R. J., Martys, N., & Bergstr?m, L. (Year). The Rheology of Cementitious Materials. ResearchGate. Retrieved from 5.NBM & CW, n.d. Recent Advances in Self-Compacting Concrete (https://www.nbmcw.com) 6.Sharma, R. and Kapoor, M. (2016). 'Implementation Challenges of SCC in Delhi Metro Phase IIIĪ». 7.Singh, A., Verma, P. and UP Expressways Authority (2021). 'High-Performance SCC Applications in Purvanchal Expressway Bridge Piers'. Indian Highways, 23/24

- 25. 24/24 24/24

![PRESENTED BY :

GYANESHWAR VAYAS

Department of civil engineering

[M.Tech]

(2421309)

Presentation

on

Self Compacting

Concrete

Under the Guidance Of

Dr.Bijan Kumar Roy](https://image.slidesharecdn.com/scc-250406164027-dd5c8e9d/85/Self-Compacting-Concrete-Composition-Properties-and-Applications-in-Modern-Construction-1-320.jpg)