Senior Design Project

- 1. Senior Design Project Jon Zickermann Jorgensen Conveyors, Inc EXP-0701

- 2. Product Tour

- 3. Hinged Steel Belt - most common belt Carries chips from machine discharge Other types: Drag Flight Magnetic Mag-Drag: magnetic / drag flight hybrid 1.5ŌĆØ, 2.5ŌĆØ, 4ŌĆØ, 6ŌĆØ, 9ŌĆØ pitch belting available Conveyors for Material Handling Product Tour

- 4. The Project

- 5. Coolant filtration: Clean coolant keeps machine tool parts cool How it works: Coolant flows thru inlet by gravity from machine Heavy media deposits on the bottom & dragged Smaller chips are picked up by rotating filter drum Spray bar sprays off the chips onto Drag Flight belt The Project The Product: Filterveyor

- 6. Two types: Dual Stage Chip Conveyor (primary) Hinged Steel Belt Coolant flows through this belt Coolant Fines (secondary) Drag Flight Single Stage Drag Flight The Project

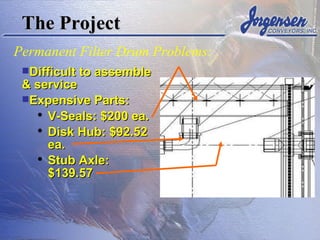

- 7. The Project Difficult to assemble & service Expensive Parts: V-Seals: $200 ea. Disk Hub: $92.52 ea. Stub Axle: $139.57 Permanent Filter Drum Problems:

- 8. The Solution: Cabinet-style assembly: Coverplate allows for easy access to drum Drum assembled & media filter fitted outside UHMW Seals far more cost effective than V-Seals UHMW Seal is static; drum rotates on this material (reducing wear) Design allows for removal of Disk Hub and Axle Spraybar is installed or serviced independently from drum Faster & easier service Adjustable spray angle The Project

- 9. Old: New: New vs. Old:

- 10. Cost Savings Old Design: $1,221.55 15 hours labor New Design $431.24 2 ┬Į planned hours labor The Project Cost Savings: $790.31

- 11. The following deserve a round of applause: Credits

- 12. THANK YOU