Shaft power measurement

- 1. UNIT-II Measurement of Shaft Power 1

- 2. âĒ Dynamometer is a device used to measure the torque being exerted along a rotating shaft so as to determine the shaft power input or output of power generating, transmitting and absorbing machinery. 2

- 3. Classification i. Absorption dynamometer:- in which energy is converted into heat by friction whilst being measured. Heat is dissipated to the surrounding where it generally serves no seful purpose. ii. Transmission dynamometer:- In which the energy is being transmitted either to or from the dynamometer is not absorbed or dissipated. After measurement the energy is conveyed to the surrounding in a useful mechanical or electrical form. iii. Driving dynamometer:- which may be coupled to either power-absorbing or power generating devices; since it may operate either a motor or a generator. 3

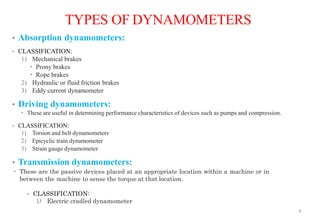

- 4. TYPES OF DYNAMOMETERS âĒ Absorption dynamometers: âĒ CLASSIFICATION: 1) Mechanical brakes ï Prony brakes ï Rope brakes 2) Hydraulic or fluid friction brakes 3) Eddy current dynamometer âĒ Driving dynamometers: ï These are useful in determining performance characteristics of devices such as pumps and compression. âĒ CLASSIFICATION: 1) Torsion and belt dynamometers 2) Epicyclic train dynamometer 3) Strain gauge dynamometer âĒ Transmission dynamometers: ï These are the passive devices placed at an appropriate location within a machine or in between the machine to sense the torque at that location. âĒ CLASSIFICATION: 1) Electric cradled dynamometer 4

- 6. ïą ABSORPTION DYNAMOMETERS 6 âĒ This dynamometers measure and absorb the power output of the engine to which they are coupled, the power absorbed is usually dissipated as heat by some means. âĒ Examples such dynamometers are: 1. Prony brake dynamometer 2. Rope brake dynamometer 3. Hydraulic dynamometer

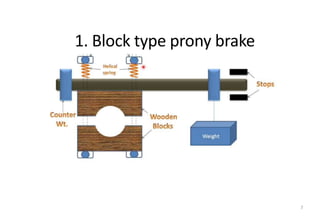

- 7. 1. Block type prony brake 7

- 8. CONSTRUCTION ï It consists of two wooden blocks placed around a pulley fixed to the shaft of an engine whose power is required to be measured. ï Blocks are clamped by means of bolts and nuts. A helical spring is provided between the nut and the upper block to adjust the pressure on the pulley to control its speed. ï The upper block has a long lever attached to it and carries a weight W at its outer end. A counter weight is placed at the other end of the lever which balances the brake when unloaded. ï In order to limit the motion of the lever, two stops provided. WORKING ï When the brake is to be operated, the long end of lever is loaded with suitable weights W and nuts are tightened until the engine shaft runs at a constant speed and the lever is in horizontal position. ï Under these conditions, the moment due to the weight W must balance the moment of frictional resistance between the blocks and the pulley. 8

- 9. ï LET, ï W = weight at the outer end of the lever (Newton) ï L = horizontal distance of the weight W from the center of the pulley (meter) ï R = radius of the pulley (meter) ï N = speed of the shaft (rpm) ï Now, the moment of the frictional resistance or torque of the shaft, ï ð = ð Ã ðŋ (Nm) And Power P = ïLIMITATIONS ïwhen the driving torque on the shaft is not uniform, this dynamometer is subjected to serve oscillations. ïAPPLIATIONS ïmeasuring power or torque developed by power source such as engines or electric motors. 9 2 / 60 2 60 1000 NT xT in Nm s N xWl in kW x ï° ï° ï ï ï ï ï ï ï ï ï―ï ï ï ï ï ï ï ï ï ï ï

- 10. 2. Band type prony brake

- 11. âĒ Consist of adjustable steel band to which are fastened blocks which are in contact with the engine brake drum. âĒ Frictional torque at the drum = Fr âĒ Balancing torque = Wl âĒ Under equillibrium condition: T = Fr = Wr in Nm âĒ Power = 11 2 / 60 2 60 1000 NT xT in Nm s NT xWl in kW x ï° ï° ï ï ï ï ï ï―ï ï ï ï ï ï ï

- 12. CONSRUCTION: ïIt consists of one, two or more ropes wound around the flywheel or rim of a pulley fixed rigidly to the shaft of the engine. ïThe upper end is kept in position while the lower end of the ropes is kept in position by applying a dead weight. ïIn order to prevent the slipping of the rope over the flywheel, wooden blocks are placed at intervals around the circumference of the flywheel. WORKING ï For the operation of the brake, the engine is made to run at a constant speed. ï The frictional torque due to rope, must be equal to the torque being transmitted by the engine. LET, âĒ W = weight at the end of the rope (N) âĒ S = spring balance reading (N) âĒ N = engine speed (rpm) âĒ D = diameter of the brake wheel (m) âĒ d = diameter of the rope (m) âĒ ( D + d ) = Effective diameter of the brake wheel 12 3. Rope brake dynamometer

- 13. 13

- 14. ADVANTAGE ï Cheap and easy construction LIMITATIONS ï Its not accurate because of change in friction coefficient of the rope with temperature. APPLICATIONS ï This type of absorption dynamometer is most commonly used. 14

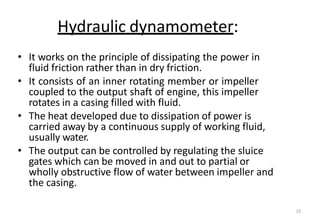

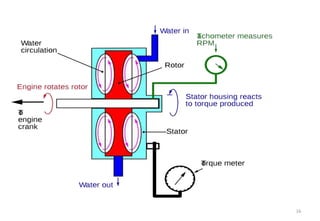

- 15. 15 Hydraulic dynamometer: âĒ It works on the principle of dissipating the power in fluid friction rather than in dry friction. âĒ It consists of an inner rotating member or impeller coupled to the output shaft of engine, this impeller rotates in a casing filled with fluid. âĒ The heat developed due to dissipation of power is carried away by a continuous supply of working fluid, usually water. âĒ The output can be controlled by regulating the sluice gates which can be moved in and out to partial or wholly obstructive flow of water between impeller and the casing.

- 16. 16

- 17. 17 TransmissionDynamometers :âĒ Power-measuring dynamometers may be transmission dynamometers or absorption dynamometers. The former utilize devices that measure torque, in terms of the elastic twist of the shaft or of a special torquemeter inserted between sections of the shaft. The torque is produced by the useful load that the prime mover, motor, or machine is carrying.

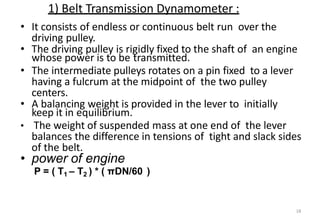

- 18. 18 1) Belt Transmission Dynamometer : âĒ It consists of endless or continuous belt run over the driving pulley. âĒ The driving pulley is rigidly fixed to the shaft of an engine whose power is to be transmitted. âĒ The intermediate pulleys rotates on a pin fixed to a lever having a fulcrum at the midpoint of the two pulley centers. âĒ A balancing weight is provided in the lever to initially keep it in equilibrium. âĒ The weight of suspended mass at one end of the lever balances the difference in tensions of tight and slack sides of the belt. âĒ power of engine P = ( T1 â T2 ) * ( ÏDN/60 )

- 20. 20 2) Epicyclic Train Dynamometer : âĒ Epicyclic train dynamometer which measures power while it is being transmitted from driving to the driven shaft. âĒ It consist of simple epicyclic gear train. âĒ The pinion is free to rotate on a pin fixed to the lever arm. âĒ The lever is pivoted about common axis of the driving and driven shaft. âĒ When the dynamometer is in operation, two tangential forces acts at the end of pinion. Torque Transmitted by Engine T = F * R = ( W * L / 2 * a ) * R Power Transmitted by Engine P = T * Ï = ( W * L / 2 * a ) * R * ( 2ÏN/60 )

- 21. âĒ Working principle: These dynamometers measure power or torque and as well provide energy to operate the device to be tested. 21

- 22. WORKING: âĒ it consists of a simple epicyclic train of gears, i.e. a spur gear. âĒ The spur gear is keyed to the engine shaft and rotates in anticlockwise direction. âĒ The annular gear is also keyed to the driving shaft and rotates in clockwise direction. âĒ The pinion or the intermediate gear meshes with both the spur and annular gears. The pinion revolves freely on a lever. âĒ A weight w is placed at the smaller end of the lever in order to keep it in position. âĒ The tangential effort P exerted by the spur gear on the pinion and the tangential reaction of the annular gear on the pinion are equal âĒ For equilibrium of the lever, taking moments about the fulcrum F âĒ 2P x a = W x L or P = WxL/ 2a R = Pitch circle radius of the spur gear in meters, and N = Speed of the engine shaft in rpm âĒ Torque transmitted, ð = ð ÃR Now, Power P= Tx2Î N/ 60 => (PxR) x 2Î N / 60 (watts) 22

- 23. WORKING PRINCIPAL: When power is being transmitted by the belt from one pulley to another, the tangential effort on the driven pulley is equal to the difference between the tension in the tight and slack sides of the belt. ï A belt transmission dynamometer, is called a Froude or Throneycraft transmission dynamometer. 23

- 24. CONSTRUCTION: âĒ It consists of a pulley A (called driving pulley) which is rigidly fixed tothe shaft of an engine whose power is required to be measured. âĒ There is another pulley B (called driven pulley) mounted on another shaft to which the power from pulley A is transmitted. The pulleys âĒ A and B are connected by means of a continuous belt passing round the two loose pulleys C and D which are mounted on a T-shaped frame. âĒ The frame is pivoted at E and its movement is controlled by two stops. WORKING: âĒ Since the tension in the tight side of the belt (T1) is greater than the tension in the slack side of the belt (T2),so the total force acting on the pulley C (i.e. 2T1) is greater than the total force acting on the pulley D (i.e. 2T2). âĒ It is thus obvious that the frame causes movement about E in the anticlockwise direction. âĒ In order to balance it, a weight W is applied at a distance L from E on the frame. âĒ Now taking moments about the pivot E, neglecting friction, 24

- 25. (Nm)âĒ Work done in one revolution= (ð1â ð2)ðð· âĒ workdone per minute= (ð1â ð2)ðð·ð (Nm) 60 âĒ Brake power = (ð1âð2)ðð·ð (Watts) 25