Sheet metal assembly verification by fea methods

- 1. 1. Introduction 2. Objective 3. Material property of components 4. CAD model 5. Unfold CAD model for sheet metal operation 6. Base FEA assembly model 7. Load and boundary condition 8. Displacement results for deferent types of element selection 9. Stress results for deferent types of element selection 10. Documents of max value of displacement & stress for deferent types of element selection 11. Conclusion of the presentation

- 5. ? Verification of FEA results by use of deferent FEA modeling methods with same element pattern and assembly method with same load and boundary condition(inertia relief) . ? It is a exercise of use of deferent testing methods and what type of assembly will satisfy it in all respect.

- 6. Material YoungˇŻs shear Poison's densitY naMe Modulus Modulus ratio aluMinuM 7.00e4 2.632e4 0.33 2.8e-9 alloY steel 2.10e5 8.203e4 0.28 7.83e-9

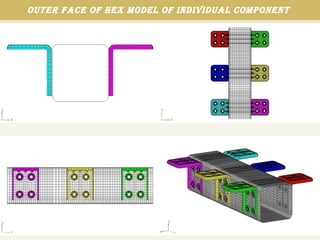

- 14. Hex model of individual component is tHe base model

- 15. Mid face of Hex Model of individual coMponent

- 16. outer face of Hex Model of individual coMponent

- 17. tet Model extracted by splitting of Hex Model of individual coMponent

- 21. iMages of area Having HigHer displaceMent value on loading condition HEX ELEMENT TET ELEMENT SHELL ELEMENT IN OUTER FACE SHELL ELEMENT IN MID PLAN

- 22. ASSEMBLY ELEMENT NODE SHOWING MAX VALUE AND RESULT TO TYPE VALUE BE TAKEN FOR REVIEW HEX MODEL 1.73E+00 TET MODEL 7.27E-01 MID PLANE MODEL 1.81E+00 HIGHER DISPLACEMENT OUTER SURFACE MODEL 1.82E+00 VALUE

- 25. ASSEMBLY ELEMENT ELEMENT SHOWING VALUE AND RESULT TO TYPE MAX VALUE BE TAKEN FOR REVIEW HEX MODEL 1.66E+02 TET MODEL 1.14E+02 MID PLANE MODEL 1.89E+02 HIGHER DISPLACEMENT OUTER SURFACE MODEL 1.91E+02 VALUE

- 28. ? The objective is achieved by getting different results from assembly by use of deferent modeling methods without change of base pattern of FEA model. ? Same assembly has to go for dynamic inertia relief test to gather output results variation.