Smart work

- 1. Smart WorkâĶ Solving Complex Engineering Problems Creatively Dibyendu De

- 2. Begin by Understanding Failures

- 3. What model does the Dog use?

- 4. RGB wavesâĶ. (Intention, Behaviour, Events)

- 5. S^2 = B => E âĒ B wave ï G wave ï R wave âĒ Stimuli x Structure = Emergent Behaviour ï Events (failures, success) âĒ Stimuli = {F, R, E, T, H, L, S} (both external & internal) âĒ Structure = {m, k, c, f, p, s} âĒ Behaviour = {S.E, K.E, A.P, Turbulence, Resonance, Surface, Noise, Entropy} âĒ Creative Response to Plan/Improve = {+, -, /, x, dy/dx,âŦ, 0, 1/x, >, <, =>, âĶ}

- 9. Bush..

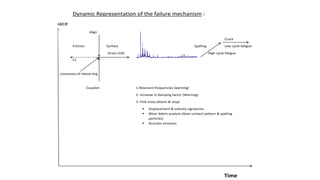

- 10. Dynamic Representation of the failure mechanism : Space Align Crack Friction Surface Spalling Low cycle fatigue Stress (HZ) High cycle fatigue L2 Looseness of sleeve brg. Coupled 1.Resonant frequencies (warning) 2. Increase in damping factor (Warning) 3. Pink noise (Alarm & stop) ï§ Displacement & velocity signatures ï§ Wear debris analysis (Gear contact pattern & spalling particles) ï§ Acoustic emission Time

- 11. Planning & Improvement âĒ Change oil from SP 320 to Servomesh 320 âĒ Use silica gel breather âĒ Electrostatic cleaner âĒ Al-bronze bush âĒ Drill a hole in the end cover of the lower bearing âĒ âĶ..