Smt custom feeder series

- 4. General Taping Requirements 1. Electronic component diameter: round 3-10m 2. Square width: 5-10mm length 5-25 3. Electronic component height: 5-25mm 4. Tape hole spacing: 12.7 or 25.4 5. Pin diameter: 0.4-1.0mm 6. Pin spacing: 5-25mm 7. Cutting foot length: 2.5-5.0mm 8. Feeder drive: motor drive 9. Electronic component packaging: tape packaging 10. Feeder size: 500*100*165 mm L/W/H 11. Applicable machine brand£ºJUKI

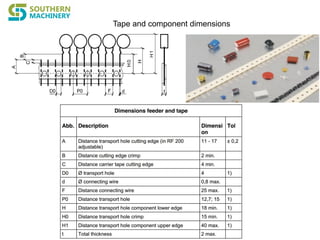

- 5. Tape and component dimensions

- 6. http£º//www.smthelp.com Radial series ,The through-hole feeder for mounter/odd-form machine. *The Radial is a revolutionary new concept from Southern Machinery that allow the placement or insertion of both surface mount and through-hole components. Can adaptive most of mounter. Auto insertion with mounters:

- 7. *General Taping Requirements Component Data for 12.7 mm and 15.0 mm (0.50 in. and 0.59 in.) Pitch Tape

- 8. *Taped Component Removal Pull Testing The taped components shall unwind (reel and cassette) or unfold (ammo-pack) with a force not to exceed 5 Newtons (17.9 oz.). Pull test shall be applied as illustrated in Figure 43.

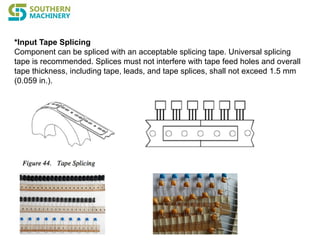

- 9. *Input Tape Splicing Component can be spliced with an acceptable splicing tape. Universal splicing tape is recommended. Splices must not interfere with tape feed holes and overall tape thickness, including tape, leads, and tape splices, shall not exceed 1.5 mm (0.059 in.).

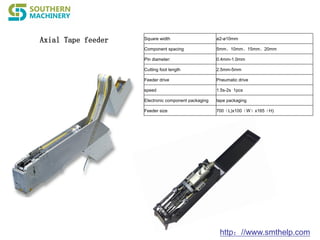

- 10. http£º//www.smthelp.com Square width ?2-?10mm Component spacing 5mm¡¢10mm¡¢15mm¡¢20mm Pin diameter: 0.4mm-1.0mm Cutting foot length 2.5mm-5mm Feeder drive Pneumatic drive speed 1.5s-2s 1pcs Electronic component packaging tape packaging Feeder size 700£¨L)x100£¨W£©x165£¨H) Axial Tape feeder

- 11. http£º//www.smthelp.com The Horizontal Stacked Tube Feeders . are high volume, high speed component feeding systems that are capable of feeding a variety of components, ranging from SMT devices to odd-form components. They feed components directly from the shipping magazines/tubes, or from in-process handling tubes. The tubes are stacked in the feeder horizontally. The components are pushed out of the bottom tube and to the pickup point by a pusher tape. automatically eject the empty tube and index the next tube into the feeding position. Key Benefits Ideal for feeding a wide variety of component packages . Dispenses components from their shipping tubes. Continuous feeding. Automatically changes tubes when one becomes empty. Handles a large inventory of components. Full tubes of components can be added to the top of the stack at any time. Ideal for use with components that can not be gravity fed because they are unstable for gravity feeding. Short cycle time ensures fast pick and place. Your investment in feeders is protected from obsolescence. Whenever your product design changes or new products are developed, feeders can be inexpensively converted by Tube Feeders Inc. to feed the new component. Control and communication by Programmable Logic Controller. Intuitive, informative Touch Screen Display panel provides all control functions for the operator and complete troubleshooting functions for maintenance or machine repair Horizontal Stacked Tube Feeders RTE-408

- 12. http£º//www.smthelp.com Vibratory Bowl Feeder These CNC machined parts feeders are applicable for precision components for the electronics and semiconductor industry (e.g. QFN, LED chips, MLCC, SOT packages and etc).

- 13. LABEL FEEDER. http£º//www.smthelp.com Reduce cost, improve quality and eliminate hand assembly. insulators, interconnect, shields, antennas . It automatically feeds and peels media from liner and presents for pick-up.Most applications with media size 3x3 to 3x28mm (width x length) can be picked with standard nozzles. Customer configurations available for < 3mm applications. Platform for up to 58x50mm (width x length) also available. Simple.Easy to use user interface with push button controls. User serviceable modular design.

- 14. http£º//www.smthelp.com The use of the solder plate is to add thickness to some components that requires more solder (3 pins transistors, USB jack pins, etc.) - PCB will still undergo normal solder paste printing process and this solder plates will be mount- ed by pick and place machines (a little off-set to the pad with solder paste on it). Then component will also be mounted on the pad. The purpose of the feeder is to lessen the cost by taking out costings on component reels or other solutions that is currently implemented in SMT production process. Label Feeder. vibratory Bowl Feeder. stacked horizontal Feeder . Solder Preform SMT feeder Tube Feeder Axial Tape Feeder Radial Tape Feeder .

- 15. Welcome inquiry 1,Please visit : www.smthelp.com 2, Find us more: https://www.facebook.com/autoinsertion 3, Know more our team: https://cn.linkedin.com/in/smtsupplier 4, Welcome to our factory in Shenzhen China 5, Google£ºAuto+Insertion 6, Looking forward to your email: shaoyong@smthelp.com