Soft contact Lens-manufacturing methods.

- 2. SOFT LENS MANUFACTURING METHODS  Molding  Spin-casting  Lathing  Molding/lathing combination  Spin-casting/lathing combination  Molding - stabilized soft

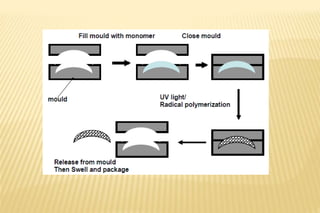

- 3. SOFT LENS MANUFACTURING MOLDING  Starts with liquid monomers  Requires controlled environment, especially humidity, and often needs to be O2-free  Polymerization initiator required (usually UV)  Subsequent steps.

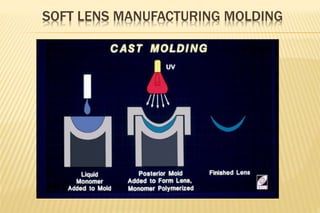

- 4. SOFT LENS MANUFACTURING MOLDING

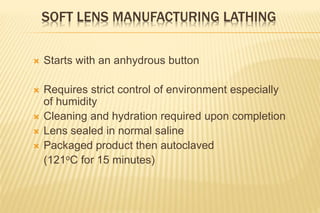

- 6. SOFT LENS MANUFACTURING LATHING  Starts with an anhydrous button  Requires strict control of environment especially of humidity  Cleaning and hydration required upon completion  Lens sealed in normal saline  Packaged product then autoclaved (121oC for 15 minutes)

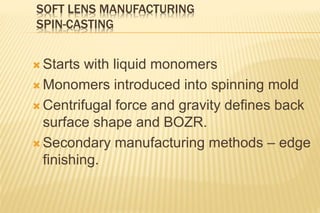

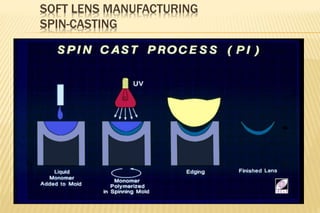

- 8. SOFT LENS MANUFACTURING SPIN-CASTING  Starts with liquid monomers  Monomers introduced into spinning mold  Centrifugal force and gravity defines back surface shape and BOZR.  Secondary manufacturing methods – edge finishing.

- 10. SOFT LENS MANUFACTURING SPIN-CASTING/MOULDING COMBINATION  front surface - spin-cast  Back surface - moulded

- 11. SOFT LENS MANUFACTURING SPIN-CASTING/LATHING COMBINATION  back surface - spin-cast  Front surface - lathed

- 12. SOFT LENS MANUFACTURING STABILIZED SOFT MOLDING  Developed for volume production  An inert water substitute is mixed with lens monomers before polymerization  Water replaces the substitute at hydration

- 13. SOFT LENS MANUFACTURING STABILIZED SOFT MOLDING  Better optical quality Quicker hydration  Enhanced reproducibility

- 14. SOFT LENS MANUFACTURING ASPHERIC  Template-following lathe  ‘Plunge’ tool, full or half diameter  x,y numerically controlled lathe  Molding - single/double-sided or spin-casting

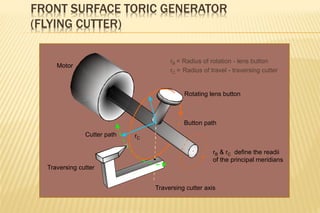

- 15. SOFT LENS MANUFACTURING TORIC  Toric machining  Crimped then worked as a sphere  Dual-axis ‘flying’ cutter (slab-off torics)  Molding - single/double-sided or spin- casting  Combinations of the above

- 16. FRONT SURFACE TORIC GENERATOR (FLYING CUTTER) rB = Radius of rotation - lens button rC = Radius of travel - traversing cutterMotor Button path Rotating lens button rB & rC define the readii of the principal meridians Traversing cutter axis Traversing cutter Cutter path rC Motor

- 17. SOFT LENS MANUFACTURING BIFOCALS  Concentric (annular) with - Distance centre - Near centre - Distance centre, progressive near - Best suited type –molding or spin casting.

- 19. SOFT LENS MANUFACTURING TINTED LENSES  Vat tinting  Reactive dyeing  Concentric rod casting  Front surface printing/stamping  Lamination - hand-painted - incorporated photograph - opaque ink stamping

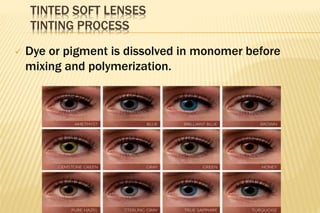

- 20. TINTED SOFT LENSES TINTING PROCESS  Dye or pigment is dissolved in monomer before mixing and polymerization.

- 21. TINTED SOFT LENSES OPAQUES Lamination was the original method • Artwork on scl - - the image is hand painted - a stock image is inserted - a thin photograph is used - an opaque ink is stamped

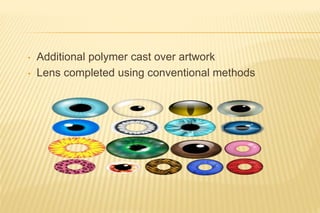

- 22. • Additional polymer cast over artwork • Lens completed using conventional methods