Solar parabolic collector

- 1. SOLAR PARABOLIC COLLECTOR ABSTRACT:  Solar Kettle is used as a principle of solar thermal heating system. Solar thermal systems convert sunlight into heat. "Flat-plate" solar thermal collectors produce heat at relatively low temperatures (80 to 140°F [27 to 60°C]), and are generally used to heat air or a liquid for space and water heating or drying agricultural products. Concentrating solar collectors produce higher temperatures.  They are most often used where higher temperature heat is desirable, there are large thermal loads, and/or where there are limitations in the area available for installing solar collectors, since they provide more energy per unit of collector surface area. They can also be applied in the production or refining of chemicals and fuels or to produce mechanical or electrical energy. The following is a discussion of concentrating systems for space or water heating. Such collectors can also be used to produce heat for absorption cooling. ECWAY TECHNOLOGIES IEEE PROJECTS & SOFTWARE DEVELOPMENTS OUR OFFICES @ CHENNAI / TRICHY / KARUR / ERODE / MADURAI / SALEM / COIMBATORE BANGALORE / HYDRABAD CELL: 9894917187 | 875487 1111/2222/3333 | 8754872111 / 3111 / 4111 / 5111 / 6111 Visit: www.ecwayprojects.com Mail to: ecwaytechnologies@gmail.com

- 2. SCOPE OF THE PROJECT: Parabolic trough technology is currently the most proven solar thermal electric technology. This is primarily due to nine large commercial-scale solar power plants, the first of which has been operating in the California Mojave Desert since 1984. Large fields of parabolic trough collectors supply the thermal energy used to produce steam for a Rankine steam turbine/generator cycle. There are two basic types of parabolic trough solar heating collectors that have been commercially developed: cylindrical parabolic troughs and compound parabolic collectors. A standard cylindrical parabolic trough has a fixed receiver/absorber positioned in the middle of the trough at or slightly above the radius across the edges of the reflector. The shape of the trough (rim angle) determines the focal point, and thus the position of the receiver. The reflector surface is usually polished aluminum, aluminized plastic, silvered glass, or stainless steal. The receiver usually has an absorber tube coated with a selective material that has a high absorption for the solar spectrum and low emittance for infrared radiation. The absorber tube may be enclosed in glass with a vacuum to reduce heat loss due to convection and radiation. Receiver temperatures can reach 750°F (400°C). WORKING PRINCIPLE In our Project, the type of concentrating system that is possible to use in a heating application is the parabolic dish. This has a bowl shaped reflector that focuses the sun onto a relatively small receiver. For optimum performance they require dual axis tracking and the receiver moves with the reflector. This complicates their practical application for water and space heating. Most parabolic dish systems are very sophisticated systems used for electricity generation or very simple systems for cooking food on a small-scale. Other types of concentrating systems have an array of

- 3. reflectors that individually track the sun and focus sunlight onto a central receiver located on a tower. Development of these systems has focused on electric power generation. ADVANTAGES Economical aspect: Least maintenance cost. No transportation from long distance No rent for electricityutilized No fuel required for operation Technical aspect: No moving parts, thus long life Noiseless operation No person required to operate the system Manufacturing aspect: Simple in construction, so easy to fabricate No heavy materials are used Safety aspect: Pollution free Less chance of accidents

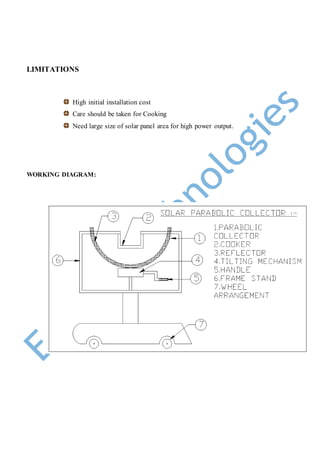

- 4. LIMITATIONS High initial installation cost Care should be taken for Cooking Need large size of solar panel area for high power output. WORKING DIAGRAM:

![SOLAR PARABOLIC COLLECTOR

ABSTRACT:

 Solar Kettle is used as a principle of solar thermal heating system. Solar thermal systems

convert sunlight into heat. "Flat-plate" solar thermal collectors produce heat at relatively

low temperatures (80 to 140°F [27 to 60°C]), and are generally used to heat air or a liquid

for space and water heating or drying agricultural products. Concentrating solar collectors

produce higher temperatures.

 They are most often used where higher temperature heat is desirable, there are large

thermal loads, and/or where there are limitations in the area available for installing solar

collectors, since they provide more energy per unit of collector surface area. They can also

be applied in the production or refining of chemicals and fuels or to produce mechanical or

electrical energy. The following is a discussion of concentrating systems for space or

water heating. Such collectors can also be used to produce heat for absorption cooling.

ECWAY TECHNOLOGIES

IEEE PROJECTS & SOFTWARE DEVELOPMENTS

OUR OFFICES @ CHENNAI / TRICHY / KARUR / ERODE / MADURAI / SALEM / COIMBATORE

BANGALORE / HYDRABAD

CELL: 9894917187 | 875487 1111/2222/3333 | 8754872111 / 3111 / 4111 / 5111 / 6111

Visit: www.ecwayprojects.com Mail to: ecwaytechnologies@gmail.com](https://image.slidesharecdn.com/solarparaboliccollector-140718215931-phpapp02/85/Solar-parabolic-collector-1-320.jpg)