Fertilizing the Prairies - Solid Waste & Recycling Magazine Article

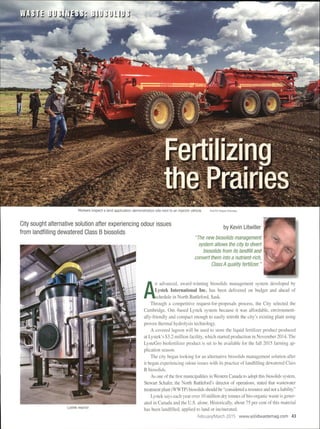

- 1. Workers inspect a land application demonstration site next to an injector vehicle. PHOTO Robert Palmese. City sought alternative solution after experiencing odour issues from landfilling dewatered Class Bbiosolids by Kevin Litwiller "The new biosolids management system allows the city to divert biosolids from its landfill and convert them into a nutrient-rich, Class Aquality fertilizer. " Lystek reactor A :advanced, award-winning biosolids management system developed by Lystek International Inc. has been delivered on budget and ahead of chedule in North Battleford, Sask. Through a competitive request-for-proposals process, the City selected the Cambridge, Ont.-based Lystek system because it was affordable, environment- ally-friendly and compact enough to easily retrofit the city's existing plant using proven thermal hydrolysis technology. A covered lagoon will be used to store the liquid fertilizer product produced at Lystek's $3.2-million facility, which started production in November 2014. The LysteGro biofertilizer product is set to be avai lable for the fall 2015 farming ap- plication season. The city began looking for an alternative biosolids management solution after it began experiencing odour issues with its practice of landfilling dewatered Class B biosolids. As one of the first municipalities in Westem Canada to adopt this biosolids system, Stewart Schafer, the Nonh Banleford's director of operations, stated that wastewater treatment plant (WWTP) biosolids should be "considered a resource and not a liability." Lystek says each year over 10 million dry tonnes ofbio-organic waste is gener- ated in Canada and the U.S. alone. Historically, about 75 per cent of this material has been landfilled, applied to land or incinerated. February/March 2015 www.solidwastemag.com 43

- 2. WASTE BUSINESS: BIOSOLIDS .. ..,:... . .....--2. MWAIMunicipal WasteAssociation V"~ Dedicaled 10 Waste Minimization and Diversion f'O/'II'IIttIyknownu AMRC Waste Diversion Planning • Waste Auditing • large Scale Organics and Recycling· Stewardship Celebrating 15 years and 500 projects nationwide. Waste Management Consulting Services Paul van derWerf,M.S<. 519-877-801-7733 TWitter: @2cL paulv@2cg.ca 2cg.ca 2cg~ Expert AWstance to Environmental Companies Technical Assistance Mergers & Acquisitions Financing & Investor Relations Government Relations Strategic growth and market development O~rational software that makes financials easy. ro~VexM~n~~}~~r;-software www :Ii TRUX Weigh·lT"" _ . .IIY'" Facility Management Software * ;1 llul.!.m.jd=~.com t~866-879-8789~ Our Best Technology Goes To Waste b d 1m Cam ri ge • Ontario 44 www.solidwastemag.com February/March 2015 "We are thrilled to be working with the community ofNorth Battleford as we expand our industry-leading solutions into Saskatchewan and across North America. We look forward to working with the City to showcase our proven technology at the open house event we are planning together for later this spring.II - Litwiller Converting biosolids into acommercial fer- tilizer high in organic matter is a win-win for both the city and local farmers, says Schafer. The new biosolids management system al- lows the city to divert biosolids from its land- fill and convert them into a nutrient-rich, Class A quality fertilizer registered by the Canadian Food Inspection Agency. The process involves acombination of heat, alkali and high shear mix- ing which boosts the ph and kills pathogens. Known as LysteGro, the fertilizer is already in high demand because it's pathogen-free, high in nutrients and organic matter, and far more cost effective than chemical altematives. The fertil- izer product is expected to help the city generate revenue and help offset costs. Higher organic matter levels in the fertil- izer mean farmers can worry less about over- application, which has been an issue on some farms in the past. In 2013, the Water Security Agency man- dated that North Battleford have a new bio- solids management solution in place by no later than November of 20l5. At the time, the city was burying the biosolids in the landfill, which was presenting other problems. Mike Dougherty, Lystek's manager of fer- tilizer production and distribution for Lystek, explained that the company works with local farmers, soil and crop specialists and land ap- plication professionals to ensure the soiI is tested prior to application and that the product is utilized properly. Generally speaking, this is done at about 3,000 gallons per acre. Because the fertilizer is injected several inches into the soil, there is almost no odour. 0 Kevin Litwiller is Lystek's director of business development. He can be reached at kevilll@lystek.coll1.