Speciality packaging

- 1. Speciality Packaging By, Monika (17) Parameshwari (18) Prashant (19) Pushpalatha (20) Rajan (21)

- 2. Snap Lock Bottom Box As we know, package design is all about the bottom locks. Sometimes Parallel Tuck In, Reverse Tuck In, Auto Lock, Snap Lock, etc. Snap Lock Bottom This is also called a 1-2-3 closure, or Houghland Bottom. This box has as a bottom closure and a top closure (can be any design/shape). The bottom closure design is more secure structure for heavier products than other types of bottom. The profile of the box nests very well and therefore minimizes paper waste. It is a versatile option for numerous applications. Advertise on all sides, top and inside flap of box. Easy top-load opening with secure, interlocking bottom assembly.

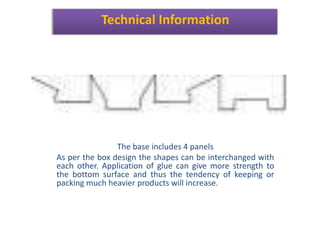

- 3. Technical Information The base includes 4 panels As per the box design the shapes can be interchanged with each other. Application of glue can give more strength to the bottom surface and thus the tendency of keeping or packing much heavier products will increase.

- 5.  Technical Aspects of Box includes Containment Protection Holding Economical Aspects includes Total cost = [ Cost/kg + Conversion charge + Profit ] * Box weight

- 6. Environmental Aspects includes Reduce Reuse Recycle Tests to be carried out Box Compression Test, BCT = [ 5.87* ECT* (T*BP)*1/2 ] Kg where, ECT is Edge Compression Test in KN/m BP is Box Perimeter in mm T is Thickness in calliper

- 7. Technical Factor PRODUCT SPECIFICATION Particulars UNIT 100 GSM 115 GSM 125 GSM 150 GSM 180 GSM 200 GSM 250 GSM 300 GSM 340 GSM Grammage Variation % +/-5 +/-5 +/-5 +/-5 +/-5 +/-5 +/-5 +/-5 +/-5 Bulk (min) CC/G 1.3 1.3 1.3 1.3- 1.4 1.3- 1.4 1.3- 1.4 1.3- 1.4 1.3- 1.4 1.3- 1.4 Burst Factor Range % 16 to 24 16 to 24 16 to 24 16 to 24 16 to 24 16 to 24 16 to 24 16 to 24 16 to 24

- 8. Paper or Material: Regular Coated Paperboard Kraft Board Metallic Paperboard Corrugated Board After Finishing : Blind Embossing Die Cutting Gloss Films PMS Colour Score Spot Varnish 3D/Motion Lenticular Printing Product Details

- 9. Cost Estimation It depends upon two factors : Absorption Costing : Direct Cost Indirect Cost Activity Based Costing

- 12. Applications • Chocolate Box Packaging • Toy Packaging • Fragrances or Perfumes Packaging • Soap Packaging (Bundle Blocks) • Gift Packaging • Food Packaging (Specially for Cakes) • Promotional Packaging

- 13. Additional Feature • Attractive Design • Less Wastage • Highly Reliable as compare to other types • Material thickness is adjustable according to your needs • Cost Effective • Additional use of Die cutting can give following shape to the butterfly feathers

- 14. Final Look

- 15. On behalf of my Team Mates Thank You

![ Technical Aspects of Box includes

Containment

Protection

Holding

Economical Aspects includes

Total cost = [ Cost/kg + Conversion charge

+ Profit ] * Box weight](https://image.slidesharecdn.com/specialitypackaging-141104015429-conversion-gate02/85/Speciality-packaging-5-320.jpg)

![Environmental Aspects includes

Reduce

Reuse

Recycle

Tests to be carried out

Box Compression Test,

BCT = [ 5.87* ECT* (T*BP)*1/2 ] Kg

where,

ECT is Edge Compression Test in KN/m

BP is Box Perimeter in mm

T is Thickness in calliper](https://image.slidesharecdn.com/specialitypackaging-141104015429-conversion-gate02/85/Speciality-packaging-6-320.jpg)